Writing in Polymers, researchers from Mexico and Ecuador have provided a comparative review of advances in magnetic polymer nanocomposite research and the application of these innovative materials in the aerospace industry.

Study: Recent Trends in Magnetic Polymer Nanocomposites for Aerospace Applications: A Review. Image Credit: aappp/Shutterstock.com

Designing Advanced Materials for the Aerospace Industry

The aerospace industry has specific requirements for components that facilitate the design of advanced materials to meet the stringent demands of the sector. Materials need to possess specific properties such as light weight, superior thermal and corrosion resistance, excellent durability, and the ability to resist electromagnetic interference.

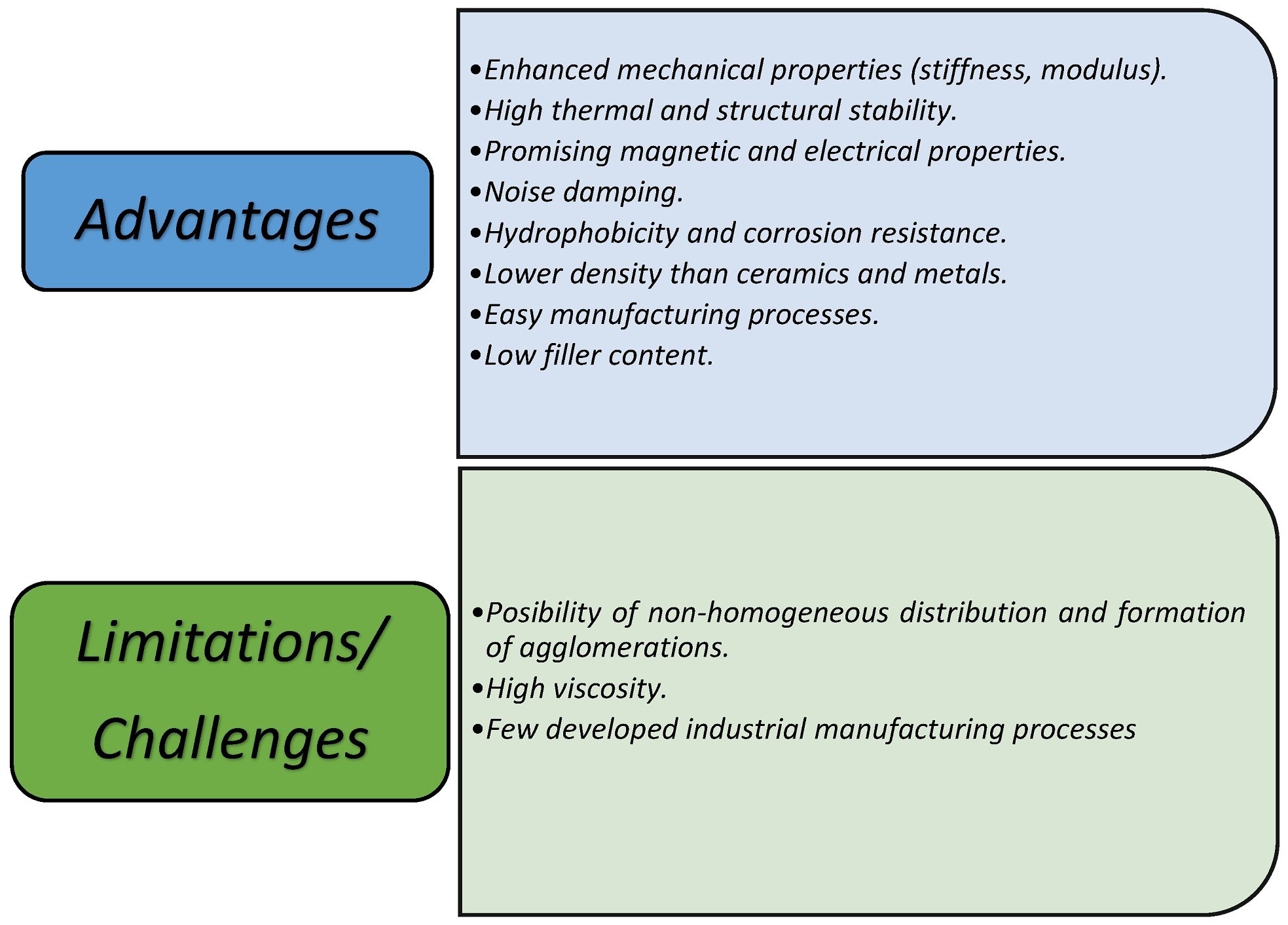

Advantages and limitations of polymer nanocomposites. Image Credit: Romero-Fierro, D et al., Polymers

Currently, there are very few advanced materials that can meet all these requirements. Traditionally, the aerospace industry has used metals such as aluminum to construct airplane parts, but they do not completely satisfy requirements such as corrosion resistance and light weight.

Research in recent years has focused on the development of advanced materials which can meet all material requirements demanded by the aerospace industry. Scientists have explored the fabrication of composites and the modification of established materials.

Polymer Composites

Polymer composites have been widely explored for this purpose in recent research. Polymers possess several benefits over other types of material, such as low cost, light weight, facile synthesis, and a wide range of mechanical, thermal, and electrical properties which are suitable for aerospace applications.

An interesting class of polymer nanocomposites has emerged in the past few years: magnetic polymer nanocomposites. The polymer matrix is reinforced with metallic nanoparticles of various configurations. Magnetic nanoparticles are metal oxides that can be magnetized by an external field, and these advanced materials possess some degree of electrical conductivity.

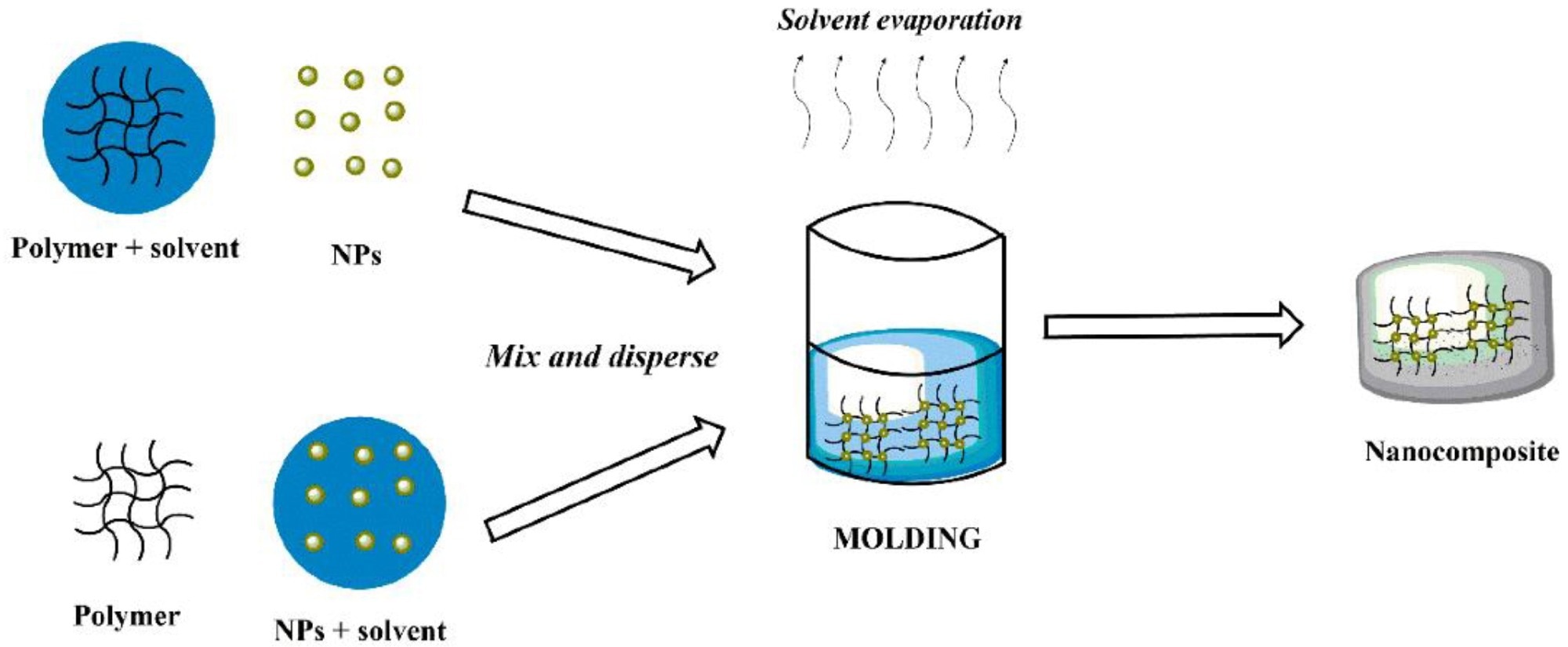

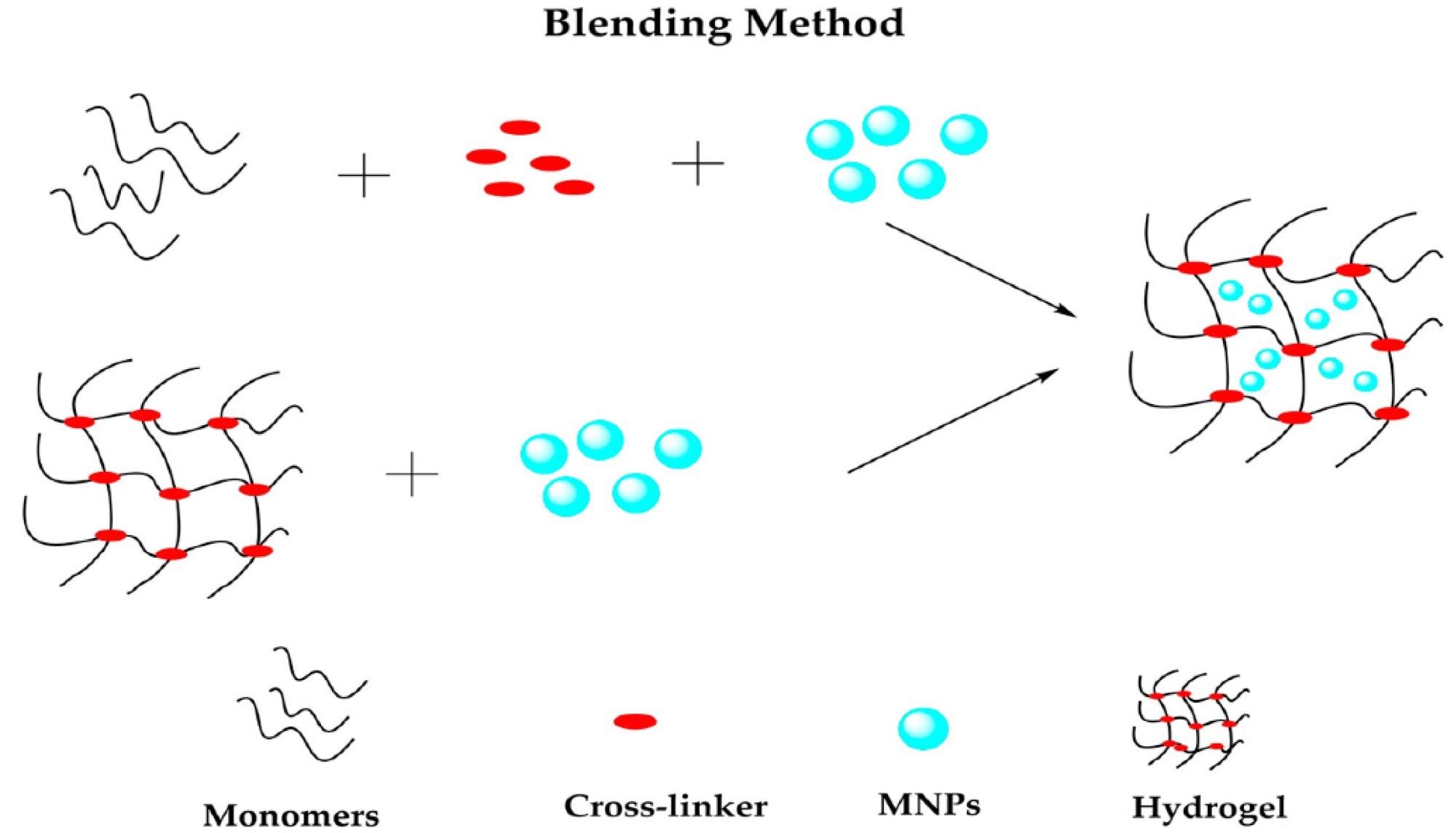

Nanocomposites can be synthesized from multiple precursor materials and by several processing routes. Synthesis methods can vary according to the characteristics of the composite material, available resources, and the type of reinforcing composite material used. Methods include chemical vapor deposition, molding, in-situ precipitation, and grafting.

Schematic representation of molding method. Image Credit: Romero-Fierro, D et al., Polymers

To fully explore the potential of magnetic polymer nanocomposites and their use in aerospace applications, there is a need for timely and comprehensive reviews of the current advances in state-of-the-art research. Fully understanding the improved properties of these advanced materials and their impact on the properties of aerospace parts will lead to the development of vastly improved nanocomposites and components.

The Paper

In order to elucidate the potential benefits that these polymer nanocomposites can bring to the aerospace sector in the 21st century, the authors have presented the most promising results in this research area. The advantages of these materials over other types of advanced and conventional materials have been considered, and future prospects have been highlighted and discussed.

Advantages and Limitations

Polymer matrix nanocomposites, including magnetic polymer nanocomposites, have several specific advantages as materials for aerospace applications. They possess enhanced mechanical properties, good structural and thermal stability, noise damping properties, lower density than metals and ceramics, hydrophobicity, and other benefits.

There are, however, some limitations to these materials, such as high viscosity, agglomeration formation, non-homogenous material distribution, and a lack of developed industrial manufacturing processes. These challenges must be overcome to improve the commercial viability of these materials for the aerospace industry.

Applications of Magnetic Polymer Nanocomposites in the Aerospace Industry

Natural phenomena can significantly damage airplanes, such as electromagnetic interference, icing, and corrosion. This can lead to aircraft being grounded and increased maintenance costs or, in the worst-case scenarios, can cause disasters and massive losses of life.

Schematic representation of blending method. Image Credit: Romero-Fierro, D et al., Polymers

Magnetic polymer nanocomposites possess properties that help protect airframes against these natural phenomena. They have been applied in EMI shielding applications, anti-corrosion coatings and paints, and structural health monitoring applications. Several composites have been explored.

Characterizing Nanocomposites

Characterizing the properties of magnetic polymer nanocomposites is an integral element of their processing (like every other material.) Structural analysis, morphological analysis, and the determination of properties are all important characterization approaches used by researchers.

Effectively characterizing nanocomposites can be challenging and frequently requires a combination of analytical techniques. Approaches used in the aerospace industry for the characterization of nanocomposites include computational modeling, atomic force microscopy, transmission electron microscopy, Raman spectroscopy, X-ray diffraction, and thermal characterization.

Future Prospects

Utilizing polymeric nanocomposites is a rapidly growing area of research and development in the aerospace industry, with one of the main aims currently in the sector being the replacement of conventional metal parts in airframes and other elements. Nanocomposites have several improved properties that cannot be replicated at the macroscale.

A key drawback to the use of composites such as magnetic polymer nanocomposites is non-homogenous mixing and material agglomeration. Overcoming this issue should be a focus of future research in the aerospace industry into the development of efficient and reliable nanocomposites, with the development of improved synthesis methods and new filler compositions playing a role.

The critical gap in industrial manufacturing processes available facilitates the need for intense development, and these must be optimized in terms of cost, energy consumption, efficiency, and other areas to satisfy commercial demands. Environmental aspects must also be satisfied.

Overall, whilst there are still several key challenges associated with the manufacture and commercial use of magnetic polymer nanocomposites and other advanced composite materials in the aerospace industry, they are highly promising. Already, they have been successfully evaluated for use in components, satisfying several key aerospace requirements. The future for these materials in this sector is looking highly interesting.

Further Reading

Romero-Fierro, D et al. (2022) Recent Trends in Magnetic Polymer Nanocomposites for Aerospace Applications: A Review Polymers 14(19) 4084 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/19/4084

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.