A paper recently published in the journal Polymers has reviewed the mechanical properties of plant fiber-reinforced geopolymers (PFRGs).

Study: The Mechanical Properties of Plant Fiber-Reinforced Geopolymers: A Review. Image Credit: mrdoggs/Shutterstock.com

Background

Fiber-reinforced cement-based composites are gaining increasing popularity. However, cement-based material preparation consumes a significant amount of energy, which does not satisfy sustainable development goals.

Geopolymer, an inorganic polymer material with a three-dimensional (3D) network structure composed of oxidoperoxy(oxo)alumane (Al-O4) and orthosilicate (Si-O4) tetrahedral units, is considered the most suitable cementitious material to replace cement.

The geopolymer production process is simple compared to conventional cement, leading to reduced carbon emissions and energy savings. These polymers can be manufactured inexpensively and using an extensive range of raw materials, such as slag, fly ash, and silica fume.

Geopolymers are also advantageous compared to organic polymer materials due to their robust antioxidant capacity, good thermal stability, high strength, and high hardness. However, geopolymers are sensitive to microcracks and possess insufficient tensile strength and flexural strength due to their brittle nature.

To overcome the brittleness of geopolymers, fibers can be added to improve their toughness, limit the growth of microcracks, and enhance their tensile strength, toughness, and ductility.

Plant fiber (PF), a natural polymer material with a rough surface, high aspect ratio, and low density, can be added to geopolymers to improve their mechanical properties. PFs are lightweight, inexpensive, biodegradable, easy to obtain, and can be processed repeatedly.

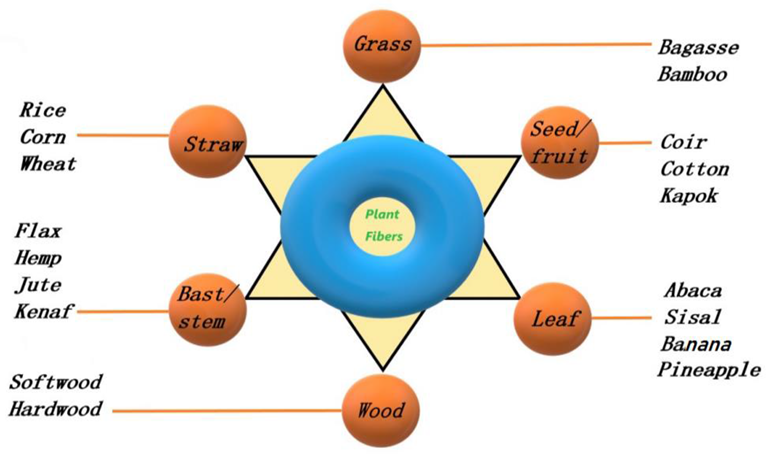

PF can improve toughness, reduce matrix shrinkage, and shorten the matrix curing time of composites as it possesses low hardness and high strength. Currently, PFRGs are studied and used in engineering applications extensively. Straw fibers, wood fibers, grass fibers, seed fibers, leaf fibers, and bast fibers are the commonly used PFs.

Classification of commonly used PFs. Image Credit: Liu, J et al., Polymers

The Study

In this paper, the authors reviewed the mechanical properties of PFRGs, specifically the impact of PF addition on the geopolymer mechanical properties, including the bending, tensile, and compression properties. They also identified the limitations of PFRG.

Compressive Strength

In PFRGs, the compressive strength depends on the bond between PFs and the matrix and the matrix material's compressive strength. Fiber type and fiber content primarily influence the compressive properties of geopolymers.

Studies demonstrated that the compressive strength of geopolymers is reduced with increasing fiber content. Specifically, the addition of more than 1% PF content reduces the PFRG compressive strength.

An evenly distributed proper amount of PF content in the matrix improved the composite compactness and reduced cracking and porosity, leading to higher compressive strength. For instance, the addition of 0.5% coir fiber content increased the compressive strength of geopolymer composites.

The addition of short cut flax fibers, bamboo fibers and lafite fibers decreased the compressive strength of geopolymers, while the addition of cotton stalk powder, coir fibers, sisal fibers, and corn straw fibers effectively increased the compressive strength.

Different fiber laying forms in the matrix also affect the composite compressive strength. The mechanical properties of geopolymers improved when woven flax fibers were added to them using a manual layup technique.

The compressive strength of PFRGs increases with increased fiber content when the fabric is laid horizontally, as the fiber can evenly distribute and absorb the load on the cross-section.

Flexural Strength

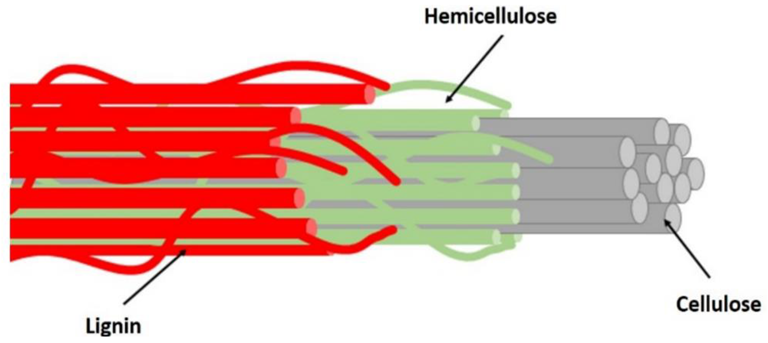

Fiber properties and fiber type play a crucial role in improving the composite fracture properties, such as flexural strength, of PFRGs. The findings of the study displayed that 5% hemicellulose, cellulose, and lignin enhanced the flexural strength of geopolymers.

However, further increases in hemicellulose and lignin content reduced the compressive and flexural strength. The addition of 0.5-1 wt% flax fibers, cotton fibers, cotton stalk fibers, coir fibers, and sisal fibers increased the flexural strength of PFRGs. Several studies demonstrated that the effect of man-made fibers on the flexural strength of PFRGs was higher compared to natural fibers.

Basic structure of PF. Image Credit: Liu, J et al., Polymers

Tensile Strength

The tensile strength of brittle-natured geopolymers can be improved by adding PFs. PFRGs demonstrated a high fracture resilience and strength when two wt% natural fiber content was added to them.

The addition of cellulose II-NA increased the density and mechanical strength and decreased the porosity of PFRGs. The compressive strength reduced while the flexural strength of PFRGs increased with the increasing flax tows content up to one wt%. However, the splitting tensile strength of the unreinforced matrix was higher compared to the flax tow-reinforced matrix.

Load-Displacement Behavior and Toughness

The higher content of sweet sorghum as fiber reinforcement decreased the unit weight of PFRGs. Although the fibers reduced the compressive strength, the post-peak toughness, bending strength, and splitting tensile strength initially increased and then decreased when the content increased to two wt%.

Sweet sorghum PFRG displayed a ductile failure in place of brittle failure demonstrated by pure geopolymers. Moreover, the addition of sweet sorghum significantly improved the post-peak ductility compared to pure geopolymers that suddenly fail at peak load.

Increasing the content of natural fibers after a specific level decreased the fracture toughness of PFRGs. For instance, the addition of 0.5 wt% cotton fibers increased the fracture toughness of PFRGs, while 0.7% and one wt% fiber decreased the toughness.

Among all composites, PFRGs reinforced with 4.1 wt% flax fiber content displayed the highest flexural strength. The addition of ten vol.% phormium tenax fibers to PFRGs significantly increased flexural strength and changed the failure from brittle to ductile.

Fiber Pretreatment

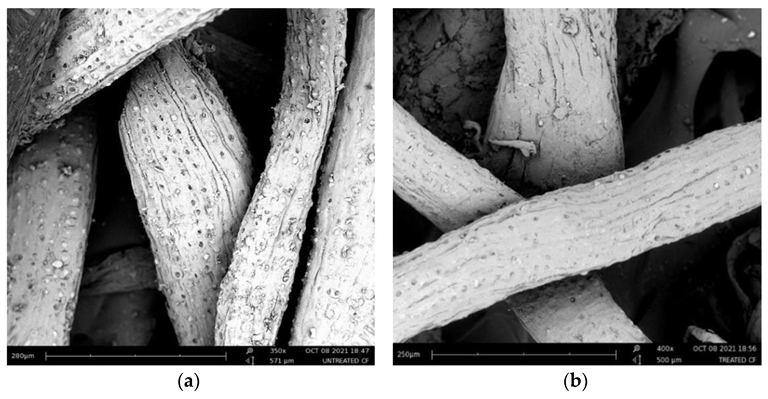

Treatment of PFs and the modification of their surface are necessary to ensure better compatibility and stronger adhesion of the fiber with the composite matrix. Treated PFs possess fewer impurities, which improves the bonding of their contact surfaces.

For instance, the pretreatment of coir fibers for 24 h with 5% sodium hydroxide eliminated impurities such as oil and wax and improved the surface texture of the fibers.

Different fiber pretreatment methods lead to different effects on PFRG properties. Alkalization, a common chemical modification technology of biological materials, is used to pretreat PFs.

Among all PFRGs, polyvinyl alcohol (PVA)-treated cotton stalk powder-reinforced geopolymers demonstrated the highest flexural and compressive strength. PVA solution substantially improved the binding properties of matrix and powder.

Similarly, the addition of alkali-treated coir fibers increased the toughness, flexural strength, and compressive strength of PFRGs. The waste abaca fiber surface properties were improved through pretreatment to enhance the adhesion between the fiber and geopolymer matrix.

The pretreatment of jute fiber, razorgrass fiber, earth palm fiber, and pine fiber using hybridization, 8% sodium hydroxide solution, keratinization, and hot water treatment, respectively, improved the compatibility between the matrix and fibers.

SEM of (a) untreated coir fibers and (b) pretreated coir fibers. Image Credit: Liu, J et al., Polymers

Conclusion

PFs can effectively increase the flexural strength compared to the compressive strength of PFRGs. Higher cellulose content leads to greater strengthening and toughening of composites. Wood fibers display better compatibility with geopolymers compared to non-wood fibers.

However, traditional fibers possess superior mechanical properties compared to PFs. PFs will precipitate sugars, such as lignin, hemicellulose, and cellulose, in an alkaline environment, which can prevent the strength development of cementitious materials. Moreover, PFs display poor adhesion to cementitious materials and easily degrade in an alkaline matrix, which adversely affects the long-term properties of PFRGs.

Surface modification and repair of PFs are essential to fully utilize their self-treatment properties. Additionally, more research is required to evaluate the interfacial toughening and bonding mechanism of PFs in the geopolymer matrix. The long-term durability of PFs also must be assessed to identify their potential applications in the exterior components of construction works.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Liu, J., Guo, G., Zhang, Y. et al. The Mechanical Properties of Plant Fiber-Reinforced Geopolymers: A Review. Polymers 2022. https://www.mdpi.com/2073-4360/14/19/4134