Electrical implants are classed as a group of implantable medical devices that can be used to treat or monitor a wide range of health conditions, from heart regulation in the form of pacemakers and hearing aid devices like cochlear implants to other advanced technologies that can treat depression and aid mobility.

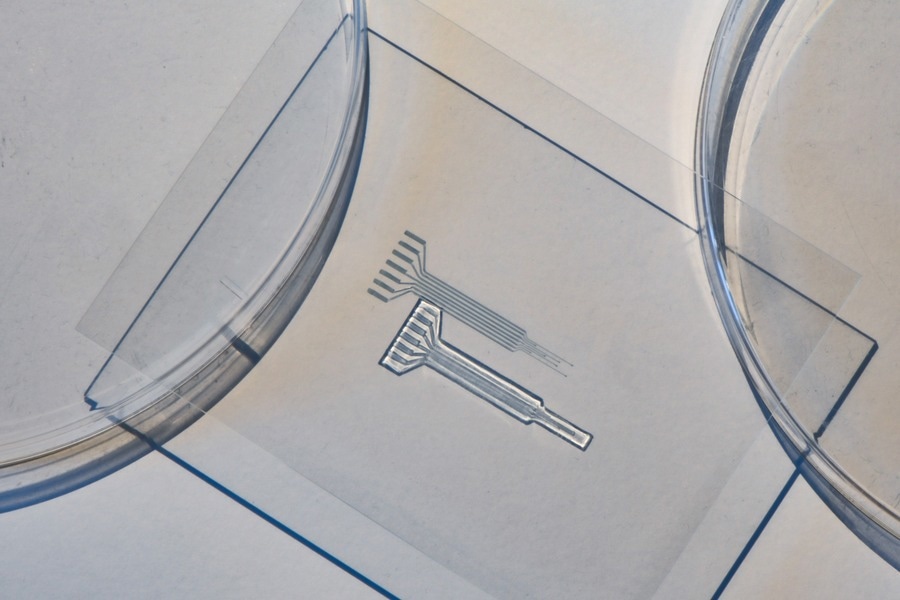

Image Credit: Felice Frankel, MIT

However, existing electrical implant technologies are made of metal and can be cumbersome, hard, and rigid, which means they can be uncomfortable and noticeable, as well as causing inflammation and, in some cases scarring, leaving long-lasting cosmetic damage to tissues.

Therefore, developing new materials and processes to manufacture electrical implantable devices that are more comfortable and safer for the user is a top priority in the field. Now researchers at MIT have developed a new Jell-O-like conductive polymer hydrogel that could be used in place of metals in implantable medical devices.

We believe that for the first time, we have a tough, robust, Jell-O-like electrode that can potentially replace metal to stimulate nerves and interface with the heart, brain, and other organs in the body.

Xuanhe Zhao, Professor of Mechanical Engineering and Civil and Environmental Engineering, MIT

High Performance Jell-O Conductivity

Metals have always been the traditional material of choice for implantable devices due to their conductivity and need to transmit electrical signals to either support vital organs – such as the heart – or to provide accurate information on a patient’s health status.

The new Jell-O-like polymer hydrogel, however, offers high-performance conductivity while proving to be as strong and soft as biological tissue. Moreover, in their research, published in the journal Nature Materials, the team claims the material can be fashioned into a printable ink for use in additive manufacturing (3D printing) techniques while retaining its key properties.

This material operates like metal electrodes but is made from gels that are similar to our bodies, and with similar water content… It’s like an artificial tissue or nerve.

Dr. Hyunwoo Yuk, Co-Founder of SanaHeal, a medical device startup

Advancing Conductive Polymers

During the 1970s, a range of conductive polymers were put to the test, which eventually went on to win the Nobel Prize in Chemistry for Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa in the year 2000 due to the material’s high electrical conductivity.

Over at MIT, the researchers set about building on these foundations and advancing conductive polymer materials by investigating their suitability for use in implantable medical devices.

Initially, as part of their mission to fabricate flexible and durable electrically conductive polymer hydrogels, the team encountered a few obstacles. For instance, their material combination of polymers and hydrogels produced something that was biocompatible yet could only transmit weak signals.

In gel materials, the electrical and mechanical properties always fight each other… If you improve a gel’s electrical properties, you have to sacrifice mechanical properties, and vice versa. But in reality, we need both.

Dr. Hyunwoo Yuk, Co-Founder of SanaHeal, a medical device startup

However, the team found that they could improve the desired electrical and mechanical properties by creating a new polymer/hydrogel formula. The team made sure they mixed the ingredients in a state known as phase separation, which meant that the two materials repelled each other.

Conductive Spaghetti-Like Strands

When in a state of phase separation, the individual ingredients are able to link their respective polymers to produce long, microscopic spaghetti-like strands, coming together as a complete material.

The electrical spaghetti is the conductive polymer, which can now transmit electricity across the material because it is continuous. And the mechanical spaghetti is the hydrogel, which can transmit mechanical forces and be tough and stretchy because it is also continuous.

Xuanhe Zhao, Professor of Mechanical Engineering and Civil and Environmental Engineering, MIT

This enables the Jell-O-like state of the material, meaning that it can now be altered for use in 3D printers allowing the team to design and print complex geometries for all kinds of electrical implants.

The researchers were able to print onto the heart and sensory system of rats and found the devices sustained stable functionality for over two months relaying electrical pulses to the heart and stimulating motor responses in the spinal cord and nerves of the sensory system.

The next steps include improving functionality so that implantable devices can last for prolonged periods as required in real-world applications. The team hopes to replace traditional materials such as metals, glass, and ceramics with something much more biocompatible and safer for patient use.

References and Further Reading

Chu, J. (2023) MIT engineers develop a soft, printable, metal-free electrode, MIT News | Massachusetts Institute of Technology. Available at: https://news.mit.edu/2023/mit-engineers-develop-soft-metal-free-electrode-0615

Zhou, T. et al. (2023) ‘3D printable high-performance conducting polymer hydrogel for All-Hydrogel Bioelectronic Interfaces’, Nature Materials. Available at: https://www.nature.com/articles/s41563-023-01569-2

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.