A research team led by chemists from the University of Liège has devised a novel polyurethane production technology that uses CO2 to produce new types of easily recyclable plastics. The study, which was published in the Journal of the American Chemical Society (J.A.C.S.), could lead to the development of completely sustainable plastics.

Image Credit: University of Liège

Commodity plastics have revolutionized the world of commerce. These plastics are ubiquitous in everyday life, used in everything from construction to clothing, cars, and food packaging. Their global use in 2019 is predicted to be close to 460 million tons.

This number is staggering, but not surprising, because plastics, also known as synthetic polymers, have met a large success thanks to their irreplaceable characteristics: they are light, cheap and incredibly versatile. However, the fact that they are difficult to recycle, or even impossible to recycle in the case of thermosets, has serious consequences.

Christophe Detrembleur, FNRS Research Director, Center for Education and Research on Macromolecules

This inability to recycle not only depletes the fossil resources needed to make them but also leads to their long-term accumulation in ecosystems and the oceans. As a result, it is critical for society as a whole to develop and produce plastics that can be easily recycled at the end of their useful life as soon as possible.

In this regard, a new method for creating readily recyclable polyurethane polymers is described in a study conducted by researchers at the University of Liège in cooperation with the Universities of Mons and the Basque Country.

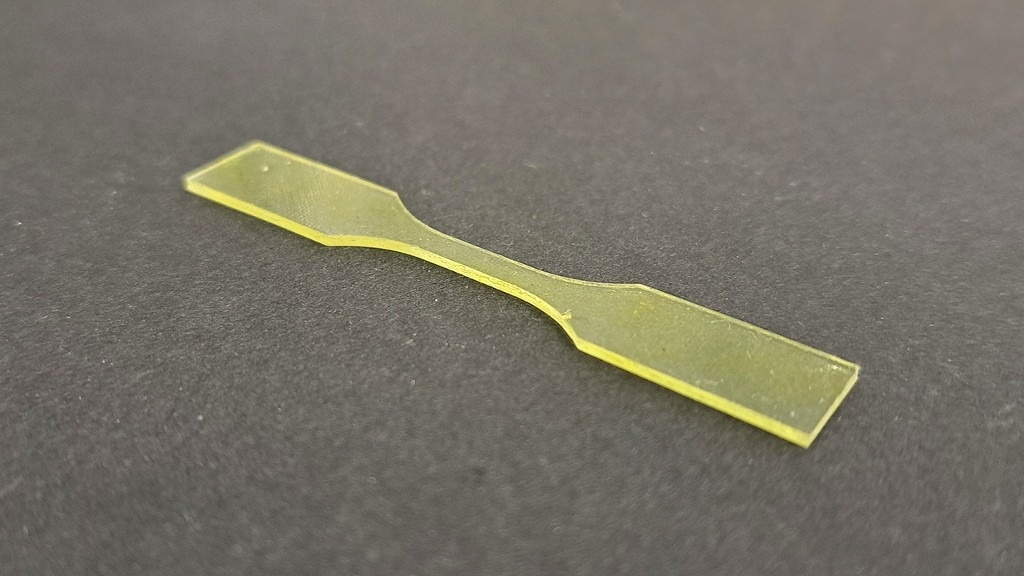

The special feature of this approach is the use of carbon dioxide (CO2) - a major emblematic waste of our society - as a raw material for the production of the building blocks, or monomers, needed to manufacture these new products. The structure of the monomers can be easily modified, making it possible to produce plastics with a wide range of properties, from highly malleable elastomers such as silicones to more rigid materials such as polystyrene.

Thomas Habets, Study First Author and Doctoral Student, Center for Education and Research on Macromolecules

Instead of having lengthy linear chains, the chemical structure of these polymers resembles a three-dimensional network. Compared to plastics comprised of lengthy molecular chains, thermosets—which are usually associated with being more difficult to recycle—are more durable because of their structure.

The polyurethanes that are produced here have novel ‘dynamic’ chemical bonds, which allow them to change shape through bond exchanges in comparatively mild reaction conditions, even if their structure is thermoset.

The most significant benefit of this new technology is its capacity to change the qualities that are available while providing several options for material recycling when it reaches the end of its useful life.

Habets added, “These new plastics can be recycled in multiple ways, either by simply reshaping them by heating them, or by mixing different types of plastic to create hybrid materials with new properties, or by breaking them down into their constituent monomers, which is ideal for eliminating additives such as dyes or recycling composites.”

This study shows that waste CO2 can be exploited directly as a chemical resource, with an eye on the future industrialization of CO2 valorization.

Detrembleur concluded, “This is the first initial study using our new building blocks and plastics but it is quite remarkable to see that our materials can already reach properties similar to those of some conventional petro-sourced plastics.”

With a broad spectrum of qualities that can effortlessly suit the needs of most everyday applications, this new technology is emerging as a possible answer for the creation of sustainable plastics.

Journal Reference

Habets, T., et al. (2023) Covalent Adaptable Networks through Dynamic N,S-Acetal Chemistry: Toward Recyclable CO2-Based Thermosets. Journal of the American Chemical Society. doi:10.1021/jacs.3c10080