Reviewed by Lexie CornerSep 18 2024

A critical step in reusing CO2 to produce sustainable fuels is linking carbon atoms together, and researchers at the University of Michigan have developed an artificial photosynthesis system that successfully binds two carbon atoms into hydrocarbons with industry-leading efficiency. The study was published in Nature Synthesis.

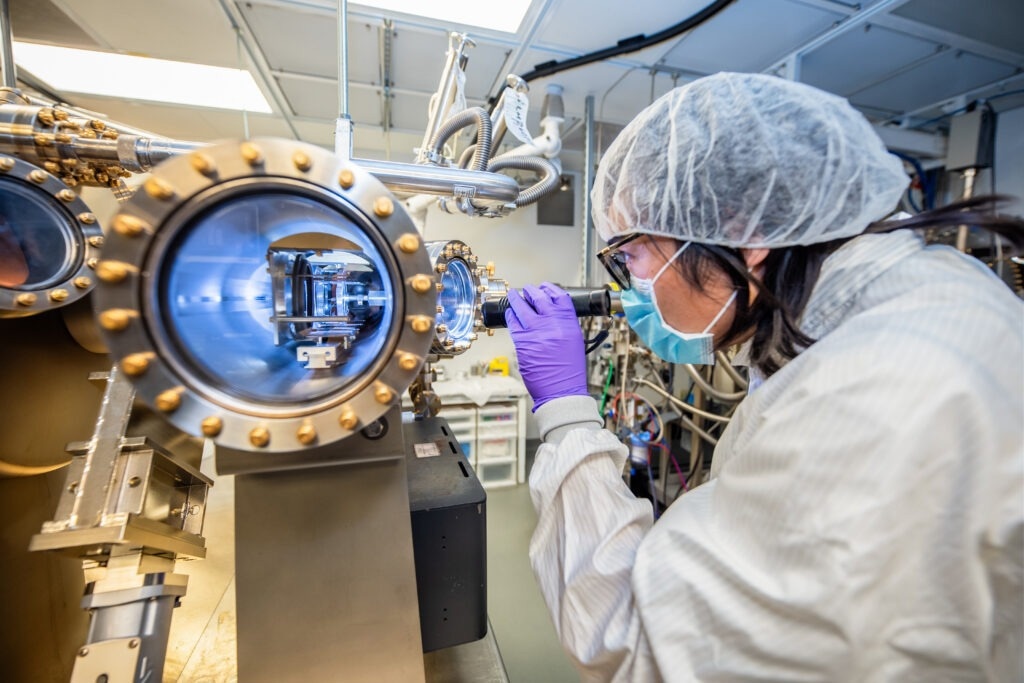

Yuyang Pan, a Ph.D. student in electrical and computer engineering and coauthor of the study in Nature Synthesis, checks on the machine growing gallium nitride nanowires on silicon in the lab of Zetian Mi. The device that the team can turn carbon dioxide and water into ethylene, is a step toward making solar fuels. Image Credit: Silvia Cardarelli

Yuyang Pan, a Ph.D. student in electrical and computer engineering and coauthor of the study in Nature Synthesis, checks on the machine growing gallium nitride nanowires on silicon in the lab of Zetian Mi. The device that the team can turn carbon dioxide and water into ethylene, is a step toward making solar fuels. Image Credit: Silvia Cardarelli

The system surpasses previous artificial photosynthesis systems in efficiency, yield, and longevity while producing ethylene. One potential application is capturing carbon dioxide that would otherwise be released into the atmosphere and using it to produce plastics, as ethylene is a commonly used hydrocarbon in plastic manufacturing.

The performance, or the activity and stability, is about five to six times better than what is typically reported for solar energy or light-driven carbon dioxide reduction to ethylene. Ethylene is actually the most produced organic compound in the world. But it is typically produced with oil and gas, under high temperatures and pressures, all of which emit CO2.

Zetian Mi, Professor and Corresponding Author, Electrical and Computer Engineering, University of Michigan

The long-term objective is to create longer chains of carbon and hydrogen atoms to eventually produce easily transportable liquid fuels. One challenge is fully removing the oxygen from water (H2O), the hydrogen source, and CO2, the carbon source.

The device uses two types of semiconductors: a silicon base and a forest of gallium nitride nanowires, each only 50 nm wide. Copper clusters, with about 30 atoms each, are dispersed along the nanowires where the conversion of carbon dioxide and water into ethylene occurs.

When the nanowires are submerged in carbon dioxide-enriched water and exposed to sunlight, the light's energy releases electrons, causing the water near the surface of the gallium nitride nanowires to split. This produces both hydrogen for ethylene synthesis and oxygen, which the gallium nitride absorbs to form gallium nitride oxide.

Copper captures hydrogen and carbon atoms from carbon dioxide, converting them into carbon monoxide. The researchers believe that two carbon monoxide molecules combine with hydrogen, receiving an energy boost from the light, and complete the reaction at the copper-gallium nitride oxide interface, with hydrogen atoms replacing the oxygen atoms.

The researchers discovered that 61 %of the free electrons generated by the light-absorbing semiconductors contributed to ethylene production. While a different silver-copper-based catalyst achieved roughly 50 % efficiency, it degraded within a few hours and required a carbon-based fluid to operate.

The Michigan team's equipment, on the other hand, operated without slowing down for 116 hours, and they have operated comparable devices for 3,000 hours.

In contrast, the Michigan team's device ran for 116 hours without slowing down, and similar devices ran for 3,000 hours. Oxygen's enhancement of the catalyst and its role in a self-healing process, combined with the water-splitting function of gallium nitride, contributed to this durability. The researchers plan to explore the device’s endurance limits in future studies.

Ultimately, the system generated ethylene at a rate over four times higher than any competing systems.

In the future, we want to produce some other multicarbon compounds, such as propanol with three carbons or liquid products.

Bingxing Zhang, Assistant Research Scientist and Study First Author, Electrical and Computer Engineering, University of Michigan

Mi's ultimate goal is to develop liquid fuels, which could make many current transportation technologies more sustainable.

The US Army Research Office funded the study.

The device was constructed at the Lurie Nanofabrication Facility and researched by the Michigan Center for Materials Characterization.

With assistance from U-M Innovation Partnerships, the team has filed for patent protection and is in the process of licensing the technology to NX Fuels, a company co-founded by Mi and financially affiliated with both Mi and the University of Michigan.

More from AZoM: Polyolefin Characterization: A Key to Sustainable and High-Performance Polymers