Reviewed by Lexie CornerOct 4 2024

Researchers are exploring the use of 3D printing to create tungsten components for extreme conditions in nuclear reactors.

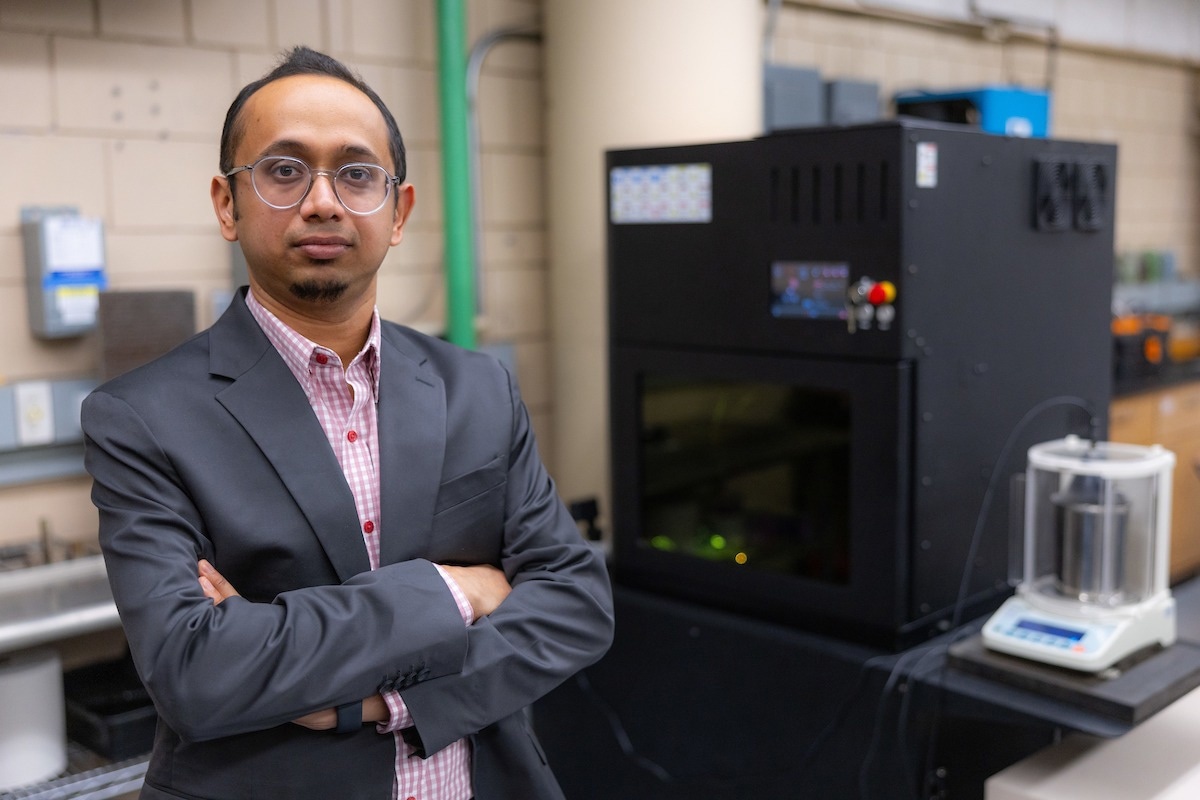

Iowa State’s Sougata Roy is leading a project to explore new ways to process tungsten for use in nuclear reactors. Image Credit: Christopher Gannon/Iowa State University.

Iowa State’s Sougata Roy is leading a project to explore new ways to process tungsten for use in nuclear reactors. Image Credit: Christopher Gannon/Iowa State University.

Despite not studying electrons, grids, or wind turbines, Sougata Roy's research has made a significant contribution to the future of clean energy.

This work in advanced manufacturing, particularly in using additive manufacturing, is about making a difference.

Sougata Roy, Assistant Professor, Mechanical Engineering, Iowa State University

The US Department of Energy has awarded Sougata Roy a $1 million, four-year grant to explore the use of additive manufacturing, or 3D printing, to produce components and shields for nuclear reactors.

“One of the major things that excites me about this project is working with nuclear energy. It’s the largest source of clean power in the United States. This emission-free electricity is important for the future,” Roy added.

According to the U.S. Energy Information Administration, nuclear power provides about 19 % of the nation's electricity, compared to around 10 % from wind turbines.

Roy, the lead researcher, will oversee the "Developing a Robust Ecosystem for Additive Manufacturing of Tungsten for Extreme Applications and Management" (DREAM-TEAM) project, with researchers from three Department of Energy labs—Ames National Laboratory on the Iowa State campus, Argonne National Laboratory in Illinois, and Oak Ridge National Laboratory in Tennessee—collaborating, as well as Yachao Wang from the University of North Dakota.

The grant is part of the Energy Department's $36 million Established Program to Stimulate Competitive Research (EPSCoR), which aims to boost energy-related research in the U.S. The team will focus on tungsten, a top material choice for fusion reactor walls due to its high melting point, erosion resistance, and low radioactive tritium absorption. However, tungsten's brittleness and expense make it difficult to process using traditional methods.

To address this, the researchers plan to experiment with 3D printing tungsten-based alloys using laser powder-blown directed-energy deposition technology. This involves layering tungsten powder with a laser under oxygen-controlled conditions. Roy, who has experience in 3D printing steel-based alloys for nuclear energy, will also acquire new equipment to measure the mechanical properties of printed samples, such as fracture toughness.

Roy emphasizes that the project's innovation lies not only in the printing process but also in the physics-based modeling and computational simulations that will complement the experimental work. Using machine learning and AI tools, the team will develop theories and simulations to guide the creation of tungsten alloys capable of enduring extreme conditions within nuclear reactors.

We will start with pure tungsten. Eventually, we will develop new alloys to resolve this cracking challenge.

Sougata Roy, Assistant Professor, Mechanical Engineering, Iowa State University

Roy emphasizes the “we” when discussing the project and its objectives.

“This is a real DREAM-TEAM, nothing like this project can be done alone,” he concluded.