Reviewed by Lexie CornerFeb 11 2025

A recent study by industry partner Thermo Fisher Scientific and Professor Shirley Meng’s Laboratory for Energy Storage and Conversion, published in Joule, found that modifying the texture of metal can significantly enhance battery performance.

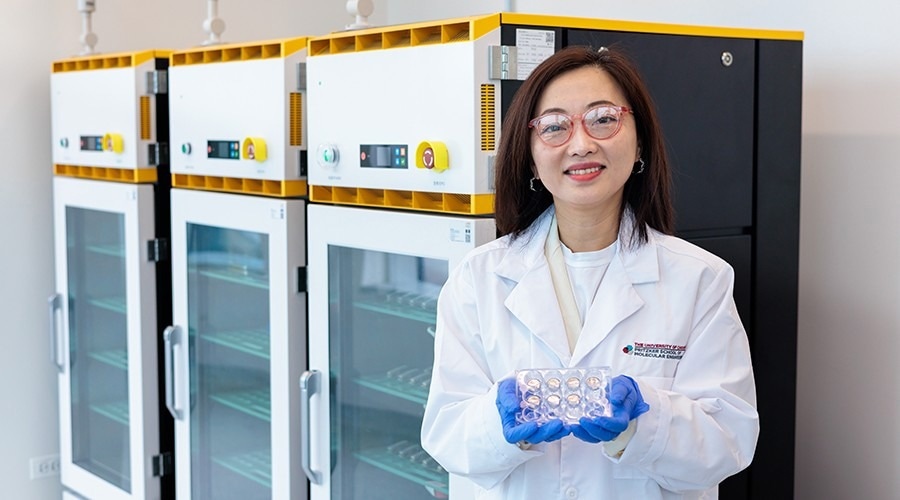

A new paper from the lab of UChicago Pritzker School of Molecular Engineering Prof. Y. Shirley Meng’s Laboratory for Energy Storage and Conversion and industry partner Thermo Fisher Scientific demonstrated how improving the texture of metal used in batteries greatly enhanced performance. Image Credit: John Zich.

A new paper from the lab of UChicago Pritzker School of Molecular Engineering Prof. Y. Shirley Meng’s Laboratory for Energy Storage and Conversion and industry partner Thermo Fisher Scientific demonstrated how improving the texture of metal used in batteries greatly enhanced performance. Image Credit: John Zich.

Researchers have explored new materials, designs, compositions, and chemical formulations to improve batteries for electric vehicles, mobile devices, and renewable energy storage systems.

However, the impact of metal texture has largely been overlooked in battery development.

Soft metals like lithium and sodium have excellent properties for being batteries’ negative electrodes, with lithium considered as an ultimate anode material for future high-energy rechargeable batteries. There is a gap in understanding the grain orientation, also known as the texture, how such factor impacts the rechargeable metal battery performance.

Shirley Meng, Liew Family Professor, Pritzker School of Molecular Engineering, University of Chicago

Research Associate Professor Minghao Zhang, the first author of the study, stated, “In our work, we discovered that adding a thin layer of silicon between lithium metal and the current collector helps create the desired texture. This change improved the battery’s rate capability by nearly ten times in all-solid-state batteries using lithium metal.”

‘Tweaking the Texture’

The optimal texture for a battery anode allows atoms to move efficiently across the surface plane, enabling faster charging and discharging.

Zhang stated, “We realized that differences in soft metal’s surface energy can really change the way it’s textured. Since batteries with lithium or sodium metal rely on these textures for favored rate capability, the team wondered if tweaking the texture of soft metals could improve power densities.”

To analyze the material, the researchers addressed a microscopy challenge by combining milling with electron backscatter diffraction (EBSD) mapping in a plasma focused ion beam-scanning electron microscope (PFIB-SEM). This approach enabled new methods for studying texture in battery materials.

Collecting texture information on soft metals is challenging, primarily due to difficulties in accessing the area of interest and the lithium and sodium metal’s reactivity. The PFIB-EBSD combination is well-suited for this study, as PFIB can effectively access the area of interest within the cell stack, producing a high-quality surface with minimal defects, while EBSD provides detailed texture information on the soft metal.

Zhao Liu, Study Co-Author and Senior Market Development Manager, Thermo Fisher Scientific

The team has collaborated with LG Energy Solution's Frontier Research Laboratory, which will help commercialize the new technology.

LG Energy Solution actively pursues research collaborations to stay ahead in the rapidly evolving battery market. As the demand for electric vehicles and energy storage continues to grow, we recognize the importance of combining our manufacturing expertise with innovative research from universities to develop next-generation battery technologies.

Jeong Beom Lee, Senior Researcher, LG Energy Solution

The researchers aim to reduce the testing pressure from 5 megapascals (MPa) to 1 MPa, aligning with the current industry standard for commercial batteries. They also plan to investigate the effect of surface roughness on sodium, which Meng has extensively studied as a low-cost and widely available alternative to lithium.

“Because we now understand how the texture forms in soft metals, we predict that sodium metal prefers to have texture for fast atomic diffusion. This means that using sodium as the battery’s anode in all-solid-state batteries could lead to a big breakthrough in future energy storage,” Zhang stated.

The study was supported by the Energy Storage Research Alliance (ESRA) (DE-AC02-06CH11357), an Energy Innovation Hub funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences. The solid-state battery with a silicon seed layer design was funded by LG Energy Solution through the Frontier Research Laboratory (FRL) program.

PFIB-SEM data collection at Thermo Scientific Americas Nanoport electron microscopy facility was made possible through funding and collaboration with Thermo Fisher Scientific on the advanced characterization of energy materials.

Journal Reference:

Zhang, M. et. al. (2025) RGrain selection growth of soft metal in electrochemical processes. Joule. doi.org/10.1016/j.joule.2025.101847