Engineers from the Massachusetts Institute of Technology and Freie Universität Berlin have created a new kind of glue that combines the germ-proof qualities of mucus, a natural substance, with the waterproof stickiness of mussels' plaques. Their findings were published in the Proceedings of the National Academy of Sciences.

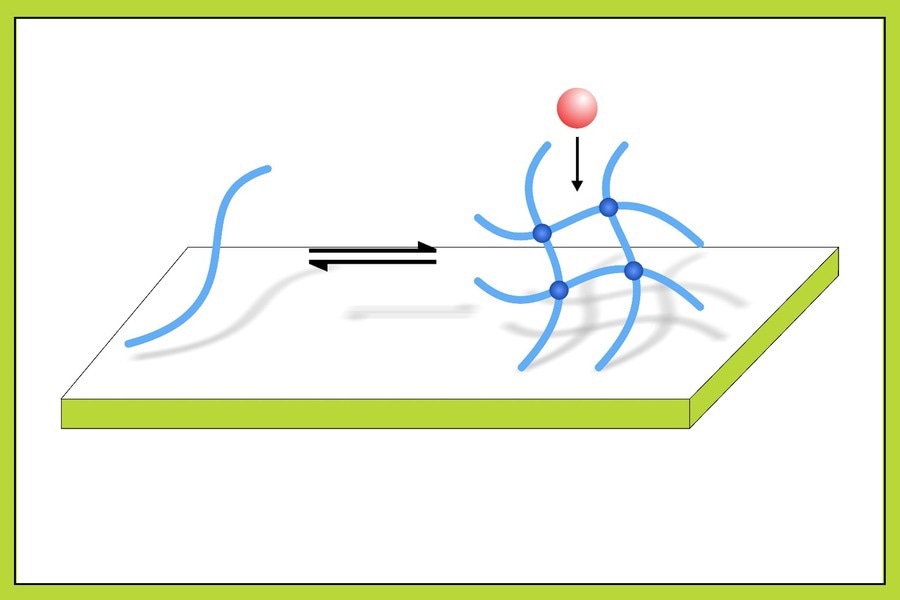

By “cross-linking” protein fibers (blue strand) from mucin and mussel-inspired polymers, MIT researchers have created a new glue that is also resistant to bacteria (red sphere) and other pathogens. Image Credit: Courtesy of the researchers

By “cross-linking” protein fibers (blue strand) from mucin and mussel-inspired polymers, MIT researchers have created a new glue that is also resistant to bacteria (red sphere) and other pathogens. Image Credit: Courtesy of the researchers

In the animal kingdom, mussels are experts at adhesion underwater. The gluey plaque that marine mollusks secrete through their feet helps them cling to rocks and ship bottoms while the waves are at sea. These resilient adhesive structures have recently inspired scientists to develop bioinspired, waterproof adhesives.

A protective layer of mucus, a slimy network of proteins, lines every part of the human body that is not covered by skin. It serves as a physical barrier against bacteria and other infectious agents. The engineers created a gel that firmly sticks to surfaces by combining mucus-derived proteins, or mucins, with sticky, mussel-inspired polymers.

Even on damp surfaces, the new mucus-derived glue maintained its sticky grip while preventing bacterial accumulation. According to the researchers, after the glue's characteristics are perfected, it could be sprayed or injected as a liquid and solidified into a sticky gel. For instance, the substance could be applied to medical implants to stop bacterial growth and infection.

Natural materials, like keratin, a fibrous substance found in feathers and hair with some chemical characteristics similar to mucus, could also be incorporated into the team's new glue-making method.

The applications of our materials design approach will depend on the specific precursor materials. For example, mucus-derived or mucus-inspired materials might be used as multifunctional biomedical adhesives that also prevent infections. Alternatively, applying our approach to keratin might enable the development of sustainable packaging materials.

George Degen, Postdoc, Department of Mechanical Engineering, Massachusetts Institute of Technology

Corey Stevens, Gerardo Cárcamo-Oyarce, Jake Song, Katharina Ribbeck, and Gareth McKinley are among the Co-authors of Degen from MIT, while Raju Bej, Peng Tang, and Rainer Haag are from Freie Universität Berlin.

A Sticky Combination

Before joining MIT, Degen worked in a research group studying mussel adhesive mechanisms as a graduate student at the University of California, Santa Barbara.

Mussels are able to deposit materials that adhere to wet surfaces in seconds to minutes. These natural materials do better than existing commercialized adhesives, specifically at sticking to wet and underwater surfaces, which has been a longstanding technical challenge.

George Degen, Postdoc, Department of Mechanical Engineering, Massachusetts Institute of Technology

Mussels release a protein-rich fluid that helps them adhere to rocks or ships. Proteins are connected by chemical bonds, also known as cross-links, which allow the secreted material to adhere to a wet surface and solidify into a gel at the same time.

Interestingly, mucin, a big protein that is the main non-water component of mucus, has similar cross-linking characteristics.

When Degen arrived at MIT, he collaborated with both Katharina Ribbeck, a Professor of Biological Engineering and a pioneer in the study of mucus, and McKinley, a Professor of Mechanical Engineering and an authority on materials science and fluid flow, to create a cross-linking glue that would combine the mucus's ability to block bacteria with the sticky qualities of mussel plaques.

Mixing Links

The MIT researchers collaborated with Haag and associates in Berlin, who are experts in creating bioinspired materials. A cooperative research team led by Haag and Ribbeck creates dynamic hydrogels for bio-interfaces.

By creating tiny, fiber-like polymers that resemble the natural mucin proteins in structure, Haag's team has created adhesives that resemble mussels and liquids that resemble mucus.

The researchers' latest study concentrated on a chemical motif in mussel adhesives: a bond between two chemical groups called “catechols” and “thiols.” These groups come together to create catechol–thiol cross-links in the mussel's natural glue, or plaque, strengthening the plaque's cohesiveness.

By attaching themselves to surfaces like rocks and ship hulls, catechols also improve a mussel's adherence.

Remarkably, mucin proteins also contain many thiol groups. Degen questioned whether mucin thiols could form a link with polymers inspired by mussels, allowing the mucins to rapidly transform from a liquid to a sticky gel.

He tested this theory by mixing solutions of synthetic polymers inspired by mussels with natural mucin proteins, then watching as the mixture solidified and adhered to surfaces over time.

“It is like a two-part epoxy. You combine two liquids, and chemistry starts to occur so that the liquid solidifies while the substance is simultaneously gluing itself to the surface,” Degen said.

Depending on how much cross-linking you have, we can control the speed at which the liquids gelate and adhere. We can do this all on wet surfaces, at room temperature, and under very mild conditions. This is what is quite unique.

Rainer Haag, Freie Universität Berlin

When the team applied various compositions between two surfaces, they discovered that the resulting adhesive held them together with forces similar to those of commercial medical adhesives used to fuse tissue. The researchers applied the gel to glass surfaces and incubated them with bacteria for a full night to test the adhesive's ability to block bacteria.

“We found if we had a bare glass surface without our coating, the bacteria formed a thick biofilm, whereas, with our coating, biofilms were largely prevented,” Degen noted.

The group claims they can increase the adhesive's hold even more with tweaking. Afterward, the substance could be a robust and protective substitute for current medical adhesives.

Degen said, “We are excited to have established a biomaterials design platform that gives us these desirable properties of gelation and adhesion, and as a starting point we have demonstrated some key biomedical applications. We are now ready to expand into different synthetic and natural systems and target different applications.”

This study was supported, in part, by the U.S. National Institutes of Health, the U.S. National Science Foundation, and the U.S. Army Research Office.