For condition monitoring, it is vital to know the viscosity of a lubricant. Therefore, field-based users require portable viscometers to immediately evaluate critical equipment while working on-site.

Other existing commercially available portable viscometer options require solvents, density, and temperature measurements to obtain results. They do not correlate with the lab viscometers, meaning the acquired data is not co-trended. Especially, in-use oils make precise viscosity measurements by any method a challenging task given their particulates, water, and combustion by-products.

The following factors are involved in the process of comparing the collected data from one instrument to another:

- Variability in the performance of the viscometers

- Wide variability in the performance of in-use oils

- Variability in application requirements

Instead of using a single benchmark for comparison of portable and laboratory viscometers, the following case study offers an approach to identify whether a portable viscometer will “do the job” given particular requirements.

Case Study

This comparison uses a SpectroVisc Q300 as a laboratory viscometer and a SpectroVisc Q3000 as a portable viscometer. The SpectroVisc Q3000 portable, solvent-free kinematic viscometer is designed for applications demanding immediate results. The SpectroVisc Q300 is a capillary (Modified Zeitfuchs) tube viscometer developed for laboratory analysis.

Both instruments were used to measure the viscosity of different samples, and the results were then compared from instrument to field viscometer. Two series of comparisons were made. The first set of samples consisted entirely of NIST-certified standards and the second sample set comprised of used oils.

Each sample was run three times, each on the SpectroVisc Q3000 and the SpectroVisc Q300 with kinematic viscosity readings taken at 40°C. The measurements from both sets were averaged and compared.

The application of NIST standards enables the comparison of accuracy of both approaches to see how closely the portable Q3000 reproduces results in line with the results of the laboratory. On the other hand, the used oil measurements are for real-world, immediate results.

As the actual viscosities are unknown, it is not possible to make absolute accuracy comparisons. The objective is to determine how the portable instrument compares to the laboratory tool across a spectrum of widely varying samples. If the results from the two approaches are “close enough” for the user, it is possible to use the portable instrument in place of the analytical instrument.

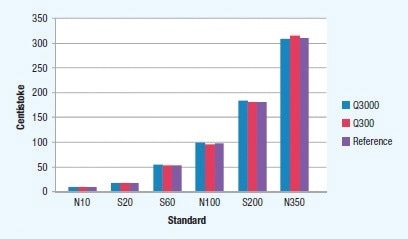

Figure 1 compares the performance of the Q3000 with the SpectroVisc Q300 over a range of certified viscosity standards. The performance of the Q3000 is consistent across the calibrated range, with a relative standard deviation below 2%.

Figure 1. Q3000 vs. Q300 performance using a range of certified viscosity standards

Results

The following results were obtained using a range of certified viscosity standards:

- Table 1 compares the Q3000 against the NIST references

- Table 2 compares the Q300 against the NIST references

- Table 3 compares results from the two solutions directly

| Table 1 |

| Q3000 |

Ref |

% Diff |

| 10.13 |

10.03 |

1.00 |

| 17.93 |

18.04 |

0.61 |

| 54.86 |

54.08 |

1.44 |

| 99.26 |

97.15 |

2.17 |

| 185.00 |

180.80 |

2.32 |

| 308.67 |

310.90 |

0.72 |

| Portable Viscometer |

| Table 2 |

| Q300 |

Ref |

% Diff |

| 10.02 |

10.03 |

0.11 |

| 18.06 |

18.04 |

0.09 |

| 53.79 |

54.08 |

0.54 |

| 96.64 |

97.15 |

0.52 |

| 180.93 |

180.80 |

0.07 |

| 314.90 |

310.90 |

1.29 |

| Lab Viscometer Q300 |

| Table 3 |

| Q3000 |

Q300 |

% Diff |

| 10.13 |

10.02 |

1.11 |

| 17.93 |

18.06 |

0.70 |

| 54.86 |

53.79 |

2.00 |

| 99.26 |

96.64 |

2.71 |

| 185.00 |

180.93 |

2.25 |

| 308.67 |

314.90 |

1.98 |

| Portable Q3000 vs. Lab Q300 |

As expected, the Q300 laboratory viscometer delivered results that are consistent with referenced ASTM norms (0.44%) for variation. The results reported by the portable Q3000 were within its expected 3% specification, and the results from the portable Q3000 and the lab-based viscometer were also within 3% (Table 3).

In the used oil comparison shown in Table 4, the portable Q3000 reported results were consistently within 3% of the bench top Q300.

| Table 4 |

| Sample |

Q3000 |

Q300 |

% Diff |

| Used Engine Oil |

54.56 |

55.24 |

1.22 |

| Used Engine Oil |

108.67 |

111.63 |

2.66 |

| Used Engine Oil |

132.00 |

128.80 |

2.48 |

| Used Process Oil |

158.33 |

161.80 |

0.98 |

| Gear Oil |

237.00 |

230.30 |

1.03 |

Conclusion

The key question is whether 3% is good enough in the context of the user’s specifications. As mentioned earlier, used oil can pose significant challenges for repeatability measurements, particularly with fuel, water, oil, and particle contamination - any of which can drive repeatability above 5% between tests of the same sample.

For OEM engine and rotating equipment providers and users, viscosity variations higher than 10% (from nominal values) are considered the first evidence of potential problems. Such issues can be immediately detected by a portable viscometer, enabling better decision making and more efficient preventive maintenance.

The introduction of new solvent-free technology for field-based viscosity monitoring delivers the performance required to detect variations of in-use oil to alert an impending problem at the equipment site.

Also, case study results reveal agreement within 3% of all samples between the portable viscometers and traditional laboratory viscometers, meaning that the SpectroVisc Q3000 Series is capable of delivering accurate results in a portable setting, with a fraction of sample volumes needed for commercial laboratory viscometers.

References

[1] Huang, C.Y., et al., Viscosity and density measurements of macromolecules. Angewandte Makromolekulare Chemie, 1999. 265: p. 25-30.

[2] van der Heyden, F.H.J., et al., A low hydraulic capacitance pressure sensor for integration with a micro viscosity detector. Sensors and Actuators B-Chemical, 2003. 92(1-2): p. 102-109.

[3] Wang, W.C., P.G. Reinhall, and S. Yee, Fluid viscosity measurement using forward light scattering. Measurement Science & Technology, 1999. 10(4): p. 316-322.

[4] Gilroy, E.L., et al., Viscosity of aqueous DNA solutions determined using dynamic light scattering. Analyst, 2011. 136(20): p. 4159-4163.

[5] Faas, R.W., A Portable Rotational Viscometer for Field and Laboratory Analysis of Cohesive Sediment Suspensions. Journal of Coastal Research, 1990. 6(3): p. 735-738.

[6] Kuenzi, S., et al., Contactless rotational concentric microviscometer. Sensors and Actuators a-Physical, 2011. 167(2): p. 194-203.

[7] Sakai, K., T. Hirano, and M. Hosoda, Electromagnetically Spinning Sphere Viscometer. Applied Physics Express, 2010. 3(1).

[8] Fitt, A.D., et al., A fractional differential equation for a MEMS viscometer used in the oil industry. Journal of Computational and Applied Mathematics, 2009. 229(2): p. 373-381.

[9] Ronaldson, K.A., et al., Transversely oscillating MEMS viscometer: The “Spider”. International Journal of Thermophysics, 2006. 27(6): p. 1677-1695.

[10] Smith, P.D., R.C.D. Young, and C.R. Chatwin, A MEMS viscometer for unadulterated human blood. Measurement, 2010. 43(1): p. 144-151.

[11] Choi, S., W. Moon, and G. Lim, A micro-machined viscosity-variation monitoring device using propagation of acoustic waves in microchannels. Journal of Micromechanics and Microengineering, 2010. 20(8).

[12] Rezazadeh, G., et al., On the modeling of a piezoelectrically actuated microsensor for simultaneous measurement of fluids viscosity and density. Measurement, 2010. 43(10): p. 1516-1524.

[13] Ballato, A., MEMS Fluid Viscosity Sensor. IEEE Transactions on Ultrasonics Ferroelectrics and Frequency Control, 2010. 57(3): p. 669-676.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.