Thermal insulation barriers have a wide variety of uses across several industries. AZoM talks to Amulya Das of Mid-Mountain Materials about their thermal insulation barriers and seals, their functions, and their applications.

Can you give a brief overview of Mid-Mountain Materials, Inc., the work you do and the industries you serve?

Mid-Mountain Materials, Inc. is a manufacturer of high temperature resistant, chemical resistant and abrasion resistant materials that are used for environmental protection, energy conservation, and emissions control in a wide variety of industrial applications. Over the years we have become a very vertically integrated company. The coated fabrics and high performance textiles we manufacture are often components of our fabricated thermal barriers. For 42 years we have been serving industries across the globe such as aluminium, automotive, aerospace, hearth, power generation, rail, welding, and many more.

Could you please explain the function of thermal insulation barriers and seals to our readers?

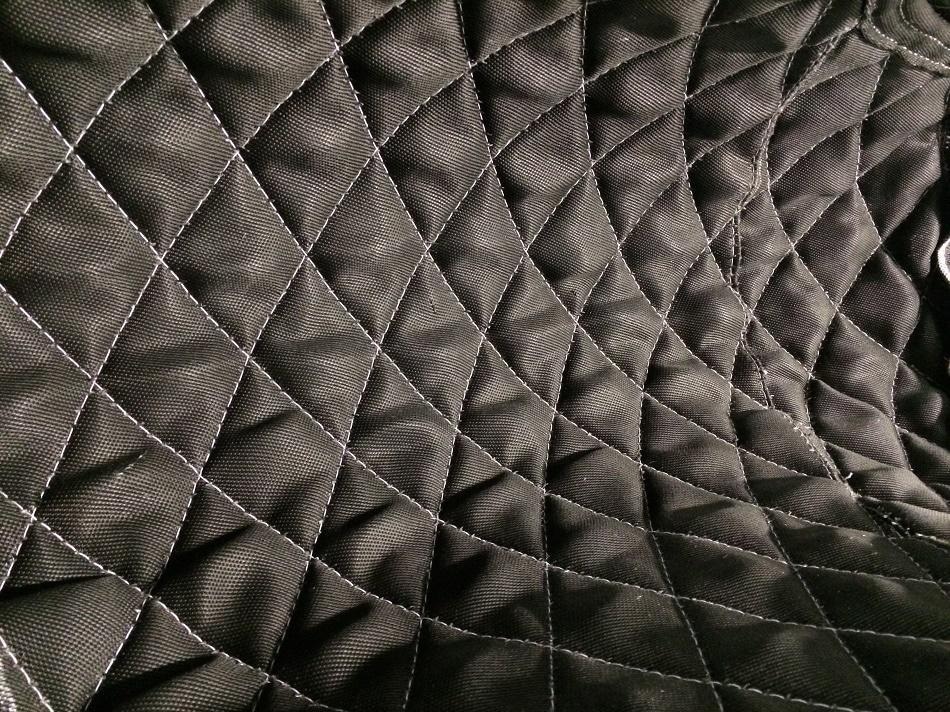

Our thermal insulation barriers and seals provides a region of insulation in which thermal conduction is reduced, or thermal radiation is reflected rather than absorbed by the lower-temperature body. The insulating capability of a material is measured as the inverse of thermal conductivity (k). Low thermal conductivity is equivalent to high insulating capability, and many of our products that are used in our thermal insulation have very low thermal conductivity.

Image Credit: Mid-Mountain Materials, Inc

You have been manufacturing coated fabrics and textiles for over 35 years – what is it about your product that makes it so successful?

The success of our products is due to a number of things. We are ISO 9001:2015 certified, and our adherence to this quality standard ensures that our products are made exactly to the specifications required, and that our customers get a high-quality product, every time. In addition, we are a very innovative company. We strive to offer products to our customers that are unique to the industry and solve the applications challenges facing our customers. We have a very broad knowledge of materials science, allowing us to engineer products for applications that do not have a clear solution at the outset.

Do you have any examples of this in practice?

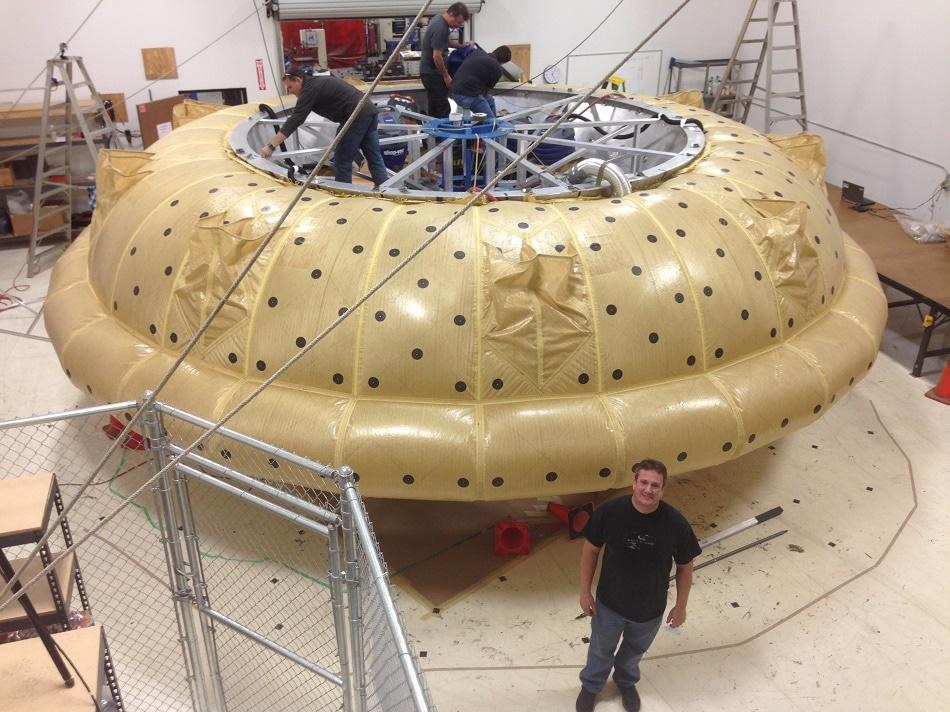

Sure! The best example we have is our collaboration with NASA and JPL to create a fabric for the Supersonic Inflatable Aerodynamic Decelerator (SIAD). This fabric had to be capable of withstanding temperatures associated with deployments at supersonic Mach numbers. The most challenging part of this application was coating a silicone compound onto Technora braided fabric which is very dimensionally unstable and heat sensitive. We developed a technique to do this, and the fabric has passed NASA’s rigorous ground testing.

Image Credit: Mid-Mountain Materials, Inc

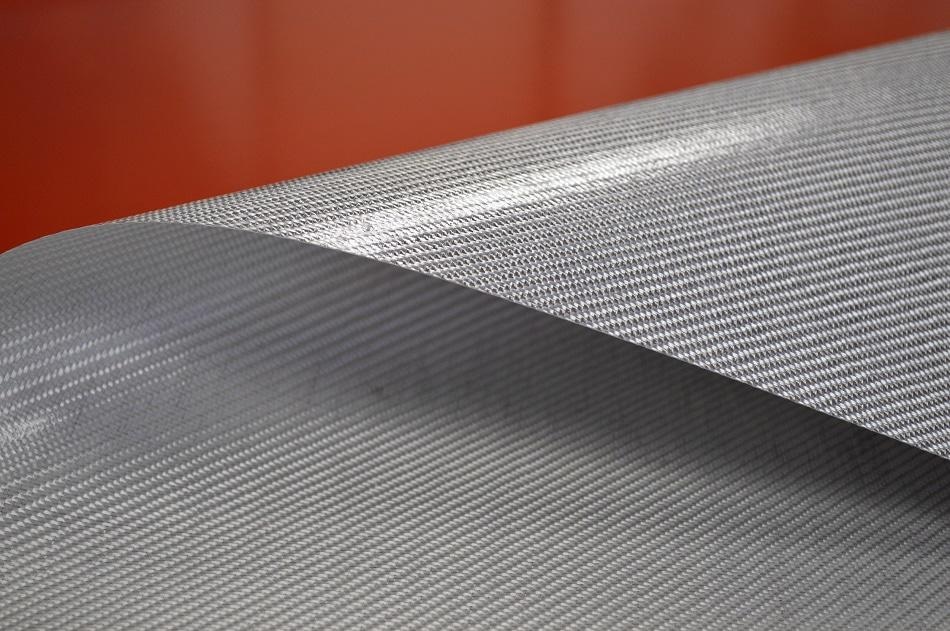

Coming back to down to earth, another example of our innovation is our ARMATEX® SilverStar 10 and SilverStar 13, which was developed from a need for a customer to have an aesthetically pleasing coated fabric for a thermal application. ARMATEX® SilverStar is not only manufactured to exceed industry standards for the fabrication of thermal insulation blankets and composite components associated with industrial insulation, it is made from a specialty fabric with an uncommon weave pattern that sets it apart from other coated fabrics. We are currently modifying the formula for FAA approval so it can be used for aircraft loading bridges, to give the passengers a more pleasing experience as they board the plane.

Image Credit: Mid-Mountain Materials, Inc

Another example is our ARMATEX® SF 17 Ultra-Premium. A 17 ounce per square yard coated fabric is the standard for insulation blankets used in industrial insulation systems. We have taken that standard product one step further by increasing the abrasion resistance and durability, offering a product that can do more than what is typically found on the market.

What advantages will the material manufacturing industry have by using Mid-Mountain products?

Mid-Mountain is a very vertically integrated company. We manufacture many of our thermal insulation barriers and seals from materials we produce, which has the advantage of greater quality control in our finished products. Our vertical integration also offers a competitive advantage, as we don’t have to outsource many of our raw materials.

How do Mid-Mountain products differ from anything else that is currently on the market?

While most of our competitors sell the same commodity products as Mid-Mountain, our products may be different in that we use high quality raw materials that adhere to our quality standards. Our competitive advantage comes from our veritcal integration, and our implementation of Lean Manufacturing which results in better manufacturing efficiencies throughout our plant. Our custom products are very different in that we have the opportunity to experiment with different materials to address the requirements of a customer’s application. We are always thinking outside the box, such as, how can we fabricate a product to extend its useful life? What colours of silicone coating can we offer that you don’t see on the market? How can we add value to our product and solve our customers’ application challenge?

What’s next for Mid-Mountain Materials, Inc.?

New business development is always happening at Mid-Mountain. We have recently introduced ARMATEX® SF2-12NF, a coated fabric for use as fire containment cargo covers should a fire break out in the cargo hold of aircraft, and ARMATEX® SBN 13-602 which used in the fabrication of protective robot covers for robots that work in extreme environments. We have also recently developed a line of custom colours for coated fabrics that you will not find anywhere else. We have added several new pieces of equipment to increase our capacity, and are developing a new, high-temperature resistant fabric for use in the automotive industry. There is always something new happening at Mid-Mountain with product development!

About Amulya Das

Amulya Das is the Director of Business Development and Corporate R&D at Mid-Mountain Materials, Inc., and is based at the company’s manufacturing facility in Arlington, Washington, USA.

Amulya is a Materials Scientist with a degree in Chemistry, and a Master’s in Chemical Technology with specialization in Textile & Polymers Science. As Director of Business Development and R&D, Amulya works closely with engineers and project managers to develop unique solutions that wi ll address their application challenges.

ll address their application challenges.

Amulya has 30 years of hands-on working experience in manufacturing, engineering, design, and Research & Development with textiles, chemicals, coatings, refractories and polymers as well as high performance materials.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.