When functional inks are used with inkjet technologies to develop microelectronic devices, any differences between the preferred design and actually printed design have to be checked; the shape and height of the printed layers are essential to ensure optimal device configuration and functionality.

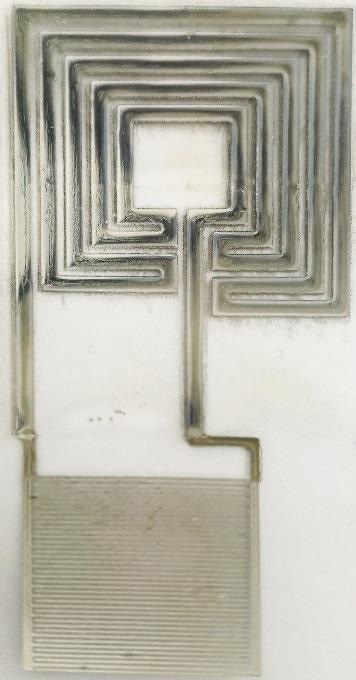

Figure 1. Antenna mold

Measurements

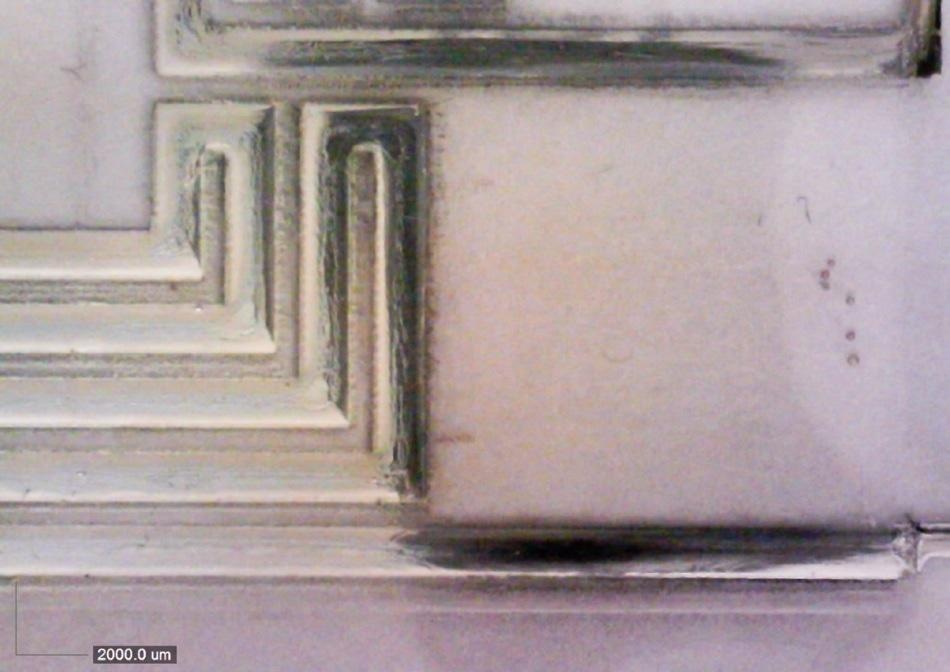

The antenna’s mold has four tracks that form five valleys that are filled with silver ink. Each mold track has a width of 600 µm and a height of 15 µm.

Figure 2. Detail of the antenna mold filled with silver ink to build up the antenna.

The device is intended to measure Escherichia coli bacteria on a hand-paper dispenser where the tag is printed on the paper. The antenna is linked to an interdigitated capacitor that acts as a bacterial sensor; if there are variations, the value of the capacitor has an impact on the frequency of the antenna resonance; these variables can be easily measured using an RF transceiver.

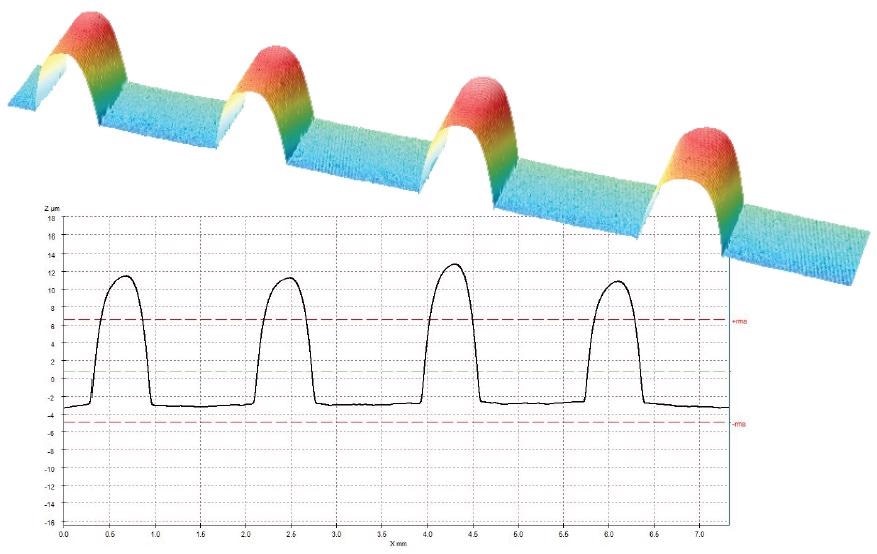

Figure 3. Detail of the mold and antenna tracks.

Presently, contact profilometers are being used in these types of devices, offering measures that are not as accurate as required.

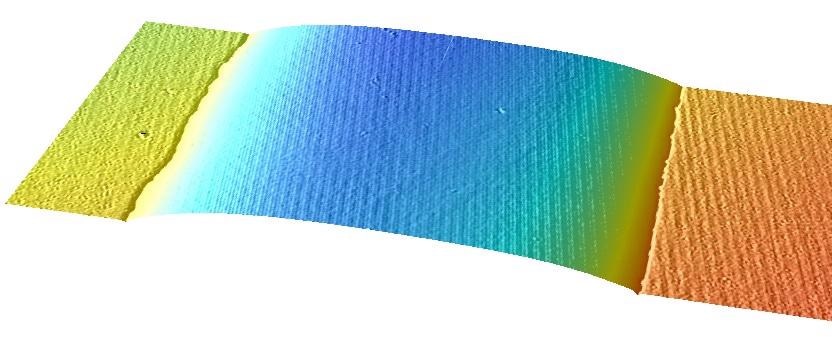

The Sensofar’s 3D optical profiler can verify the mold height and estimate whether there will be an adequate layer of silver bulk to obtain the desired conductivity for good performance.

Figure 4. (a) 3D topography of the antenna’s mold printed on PEN substrate. (b) Profile of the antenna’s mold.

Conclusions

By checking with a Sensofar Plμ neox using the confocal technique with a 20x brightfield objective, the RF antenna’s shape was achieved as preferred, a sufficient silver layer was obtained, and good conductivity was guaranteed.

Figure 5. 3D topography showing mold track detail.

The Sensofar equipment offered non-contact 3D surface profilers on the basis of three technologies: Interferometry, Confocal, and Focus Variation techniques. It also enabled high-resolution measurements to be obtained in a quick and non-destructive manner, with easy-to-use software for technical support.

This information has been sourced, reviewed and adapted from materials provided by Sensofar.

For more information on this source, please visit Sensofar Metrology.