Floating photovoltaic installations are a novel concept integrating land-based PV technology with innovative floating systems. Several floating PV installations have been set up at a worldwide level on different types of freshwater bodies including lakes, as well as agricultural and irrigation ponds.

For small islands like Malta, enclosed by saline territorial waters, the potential impact of salt deposition on the performance of floating solar PV systems must be taken into account when thinking about offshore installations. To exploit the total potential of such a solar energy system, performance and efficiency should be at the maximum possible levels, thus the number of factors that can impact these two measures should be inspected and considered.

Dust buildup on PV panels is extensively known to greatly decrease performance; on the other hand, the effect of salt has not been examined. Since salt is not as opaque as dust, it is not obvious how much it would shade PVs or to what level it would collect after repetitive panel wetting.

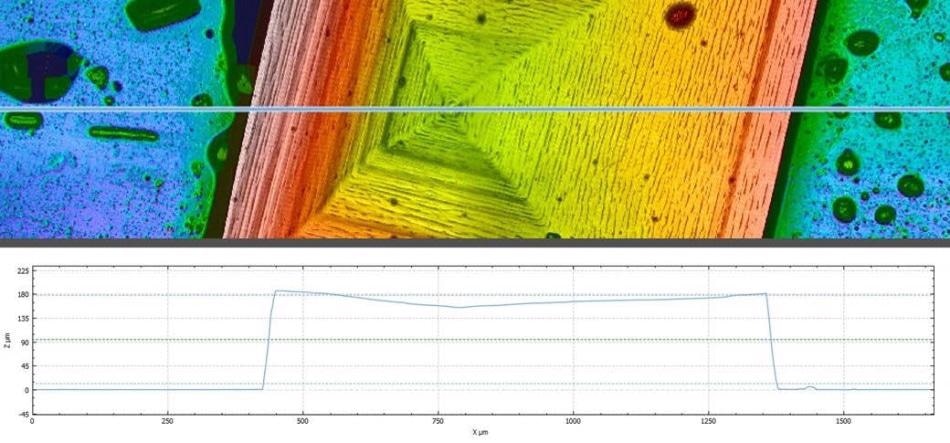

A series of wetting tests with solutions of different salt concentrations are being performed along with light transmission testing and opacity testing to examine the performance of PVs when exposed to an oceanic environment. White light optical profilometry along with microscopy is used to acquire the thickness measurements of the deposited salt layer so as to measure how long panels can be subjected to salt solutions without any adverse effects.

Measurements

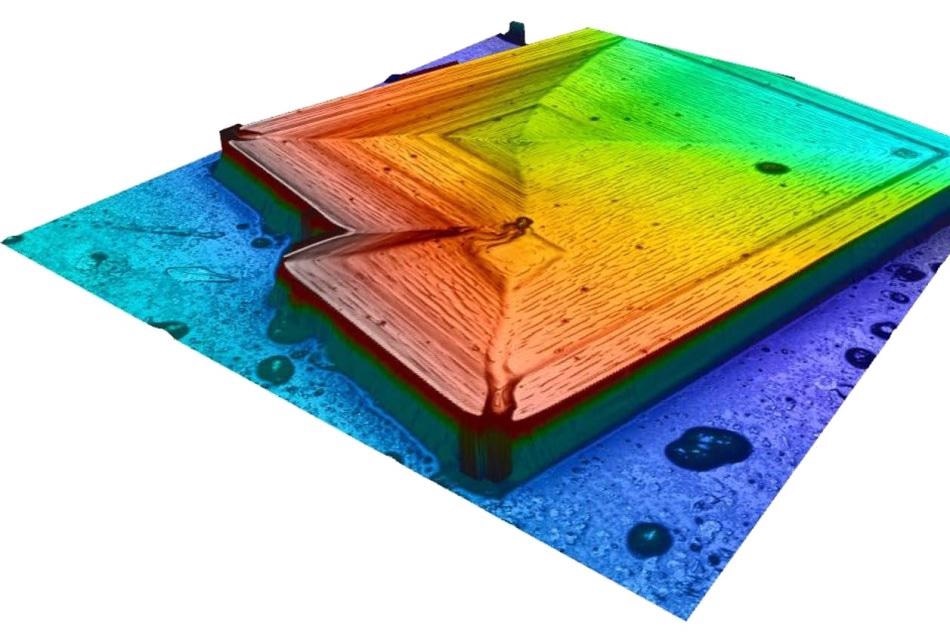

The test samples comprise of glass microscope slides (26x76 mm) coated with salt together with the panel wetting experiments. The features of the deposited salt were examined using confocal profilometry because of the high inconsistencies in the surface features across samples.

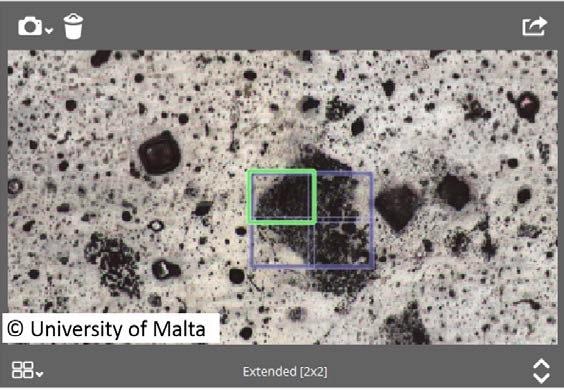

An overview of the samples was first acquired using the 2.5X magnification brightfield objective so as to obtain an idea of the salient characteristics.

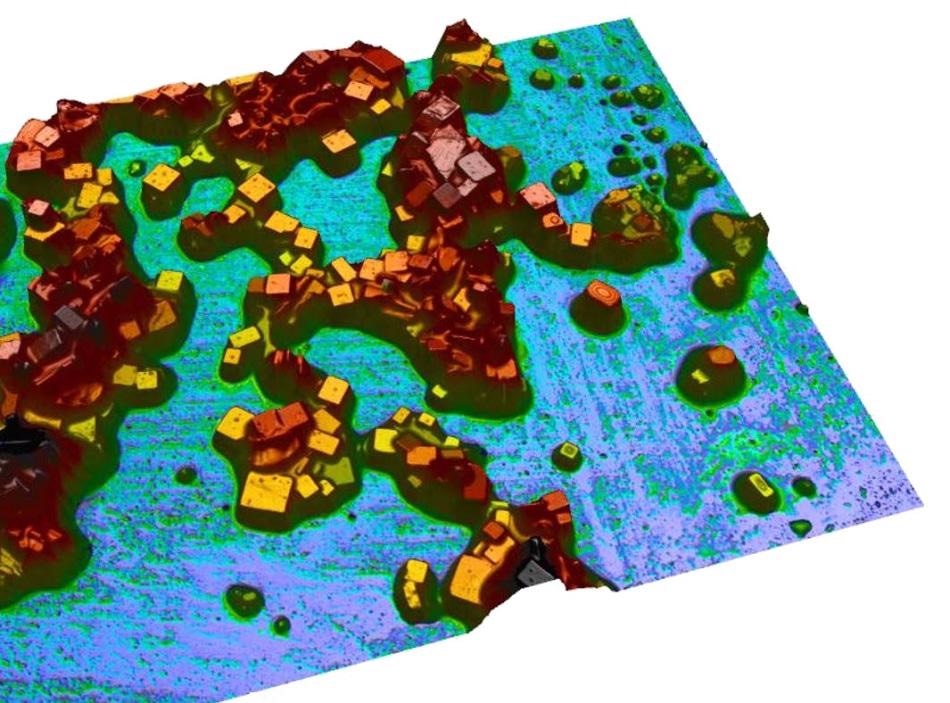

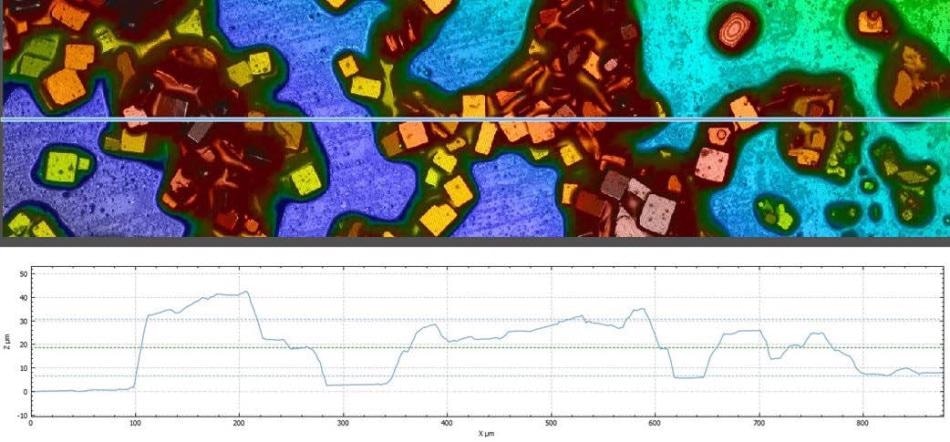

The crystal features of areas of interest were then taken using a 20X magnification objective in brightfield mode.

The 3D profiles were then processed so as to gather information such as salient features and crystal height (and an approximate thickness).

Post-processing features combined into the software were essential for exact measurement providing flattening algorithms as well as options to reinstate the missing data points as required.

Conclusions

By using Sensofar’s S neox 3D optical profiler, it is feasible to measure glass microscope slides coated with salt. The 2.5X brightfield objective is used to obtain an enlarged overview of the sample and find the areas of interest prior to taking the measurement.

The Confocal method (20X brightfield objective) has been used for determining the roughness and thickness of these parts effectively, obtaining high-resolution topographies with sufficient reliability to record conclusions about critical dimensions, thicknesses, and the distribution of particles on the surface. In certain cases, lengthy measurements have been essential to measure larger areas.

This information has been sourced, reviewed and adapted from materials provided by Sensofar.

For more information on this source, please visit Sensofar Metrology.