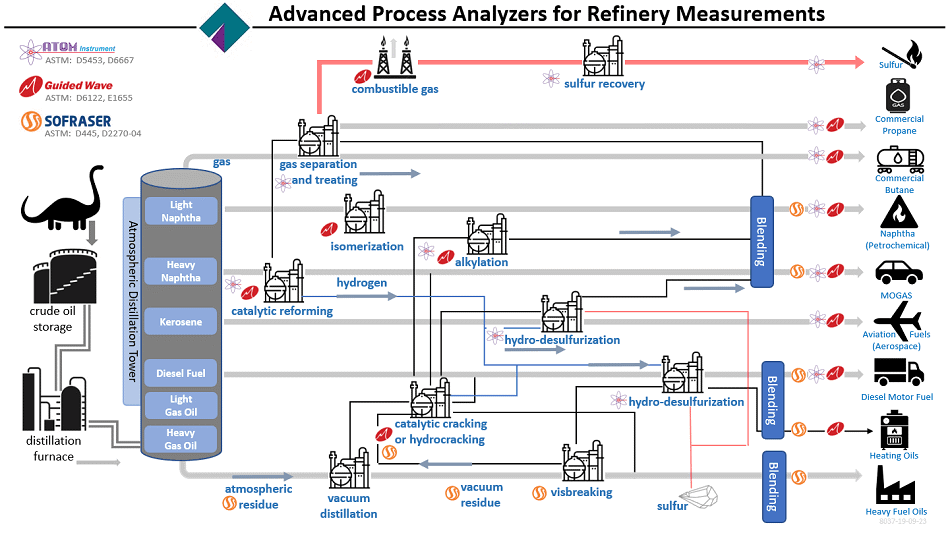

Refineries process crude oil into useable fossil fuel products. The process starts by taking the raw crude oil from the well and running it through a distillation tower. As the fluid is heated it passes through various levels or trays inside of the tower. Different densities of hydrocarbon products are then separated. With the lightest hydrocarbon chains rising to the top of the column and the heaviest falling to the bottom.

Now that the mixture of hydrocarbons found in the raw crude oil has been separated, they can be individually processed into different kinds of fossil fuel product. The lightest hydrocarbon chains such as methane, propane, and butane can be diverted to the distillation furnace and feed the fires that heat the distillation process or they can be processed for sale. The TraceS-1000 manufactured by ATOM Instrument can be used to inspect the desulfurization process and ensure that only trace amounts (0-1000 ppbv) are present in the end product.

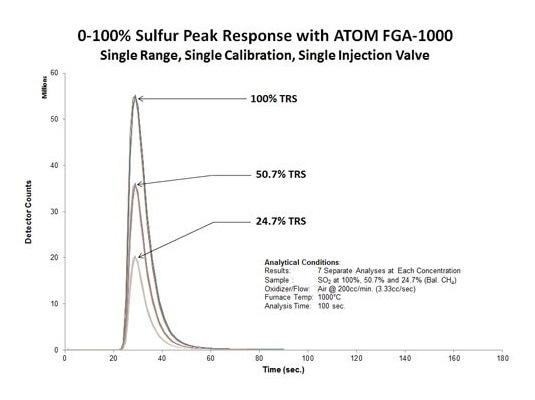

Any waste fuel from the distillation process is generally incinerated in a Flare Stack. High Sulfur levels cannot be safely incinerated in the Flare in accordance with US EPA CFR 60.18 subpart Ja. ATOM's FGA-1000 Total Sulfur Analyzer can be used to measure %vol total sulfur according to the EPA standards to allow proper diversion of high sulfur content to an SRU safely to be reused and/or re-purposed for other areas of the refinery.

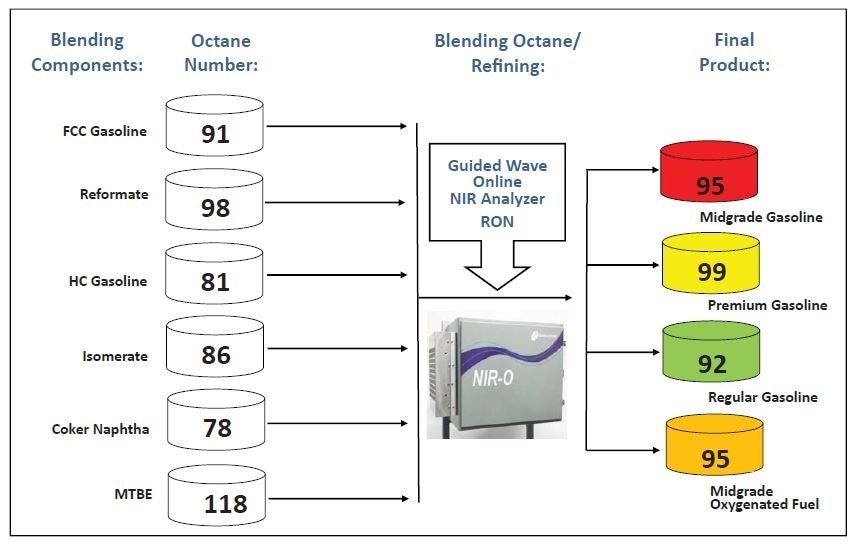

Other middleweight products such as kerosene, gasoline, and naphtha can be sent to a fuel blender where an infinite number of grades or blends can be produced to meet the requirement of the end customer. In order to achieve the best possible margin, various analyzers can be installed inline to inspect the fuel blending process.

If a higher octane rating is required, light naphtha can be sent through the isomerization reactor. During a single pass through the isomerization process, normal paraffins are converted to isoparaffins. Alternatively, the isomerization unit can be used to convert linear molecules (i.e. pentane) into higher-octane branched molecules for fuel blending. Also used to convert linear n-butane into iso-butane for use in the alky unit. During the isomerization process, Near-Infrared spectroscopy can be used to optimize catalyst conditions.

Naptha and other petroleum compounds can be converted to use chemicals as part of the crude to the chemical process. This often occurs in a series of Steam or Catalyst Cracking tanks. NIR can be used to monitor the PIONA (Paraffins, Isoparaffins, Olefins, Napthenes, Aromatics) and the Distillation curve during the cracking process. The Reformate or Platformate can then be feed into the fuel blender to adjust the cetane and octane values of the finished product.

Additionally, regulations such as the American Tier III, European Euro 6 or the Indian Bharat VI set quantitative limits on the permissible amount of Sulfur Dioxide (SO2), Nitrogen Oxide (NO) and Nitrogen Dioxide (NO2), commonly referred to as NOx that are released during combustion. Sulfur and Nitrogen levels are both controlled under these regulations due to the health and environmental impact. To ensure that the final product created at the refinery meets these regulatory requirements, spot inspections for the Total Sulfur and Total Nitrogen can be conducted with ATOM's XT-2000 Laboratory Analyzer.

Refineries interested in being compliant with ASTM D5453 can utilize the real-time information provided by ATOM Instrument patented Ultraviolet Fluorescence Systems to determine the Total Sulfur in their fuels.

Refineries interested in maximizing profits commonly want to determine the Fuel Octane Numbers (i.e. RON, MON) with online near-infrared (NIR) spectroscopic analyzers such as Process Insights’ NIR-O. Spectroscopy is a tool compliant with ASTM D6122 which enables refineries to blend expensive high octane feedstocks with less expensive low octane naphtha while maintaining required octane levels and minimizing costs.

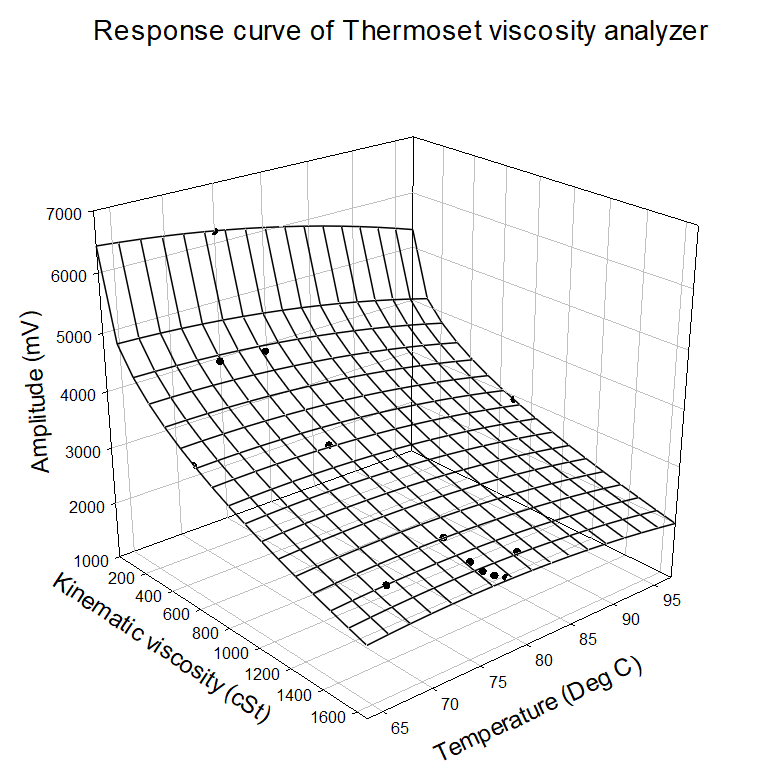

Viscosity is another important physical quantity in the refining of crude oil. During the fuel blending process, a heavy and high viscosity stream is mixed with a light and low viscosity stream to achieve the desired end product. The expected blend of petroleum products with the correct viscosity level can be achieved thanks to SOFRASER Thermoset-LT, which provides viscosity measurement at constant reference. The Thermoset- KV is the only online direct kinematic viscosity analyzer that is easily correlated with ASTM D445.

SOFRASER MIVI process viscometer is an alternative analyzer that measures the viscosity at the line temperature and can be combined with Temperature Compensated Viscosity calculation.

When the fuel blender is producing petroleum products that are intended to be used as lubricants, then the analyzers can be used to monitor the Viscosity Index according to ASTM D2270.

Unit operations producing or processing high viscosity streams, like Visbreaking, bottoms of atmospheric distillation, and vacuum distillation residues can be monitored by MIVI sensors or Thermoset analyzers for improved process control.

After the different grades of fuel have been appropriately blended, they can be sent by a pipeline to the terminal for shipment all around the world. At the downstream terminal, Fuel Identification by NIR spectroscopy ensures that the correct and in-specification petroleum products are loaded onto the ships and sent to the customer.

Further to the atmospheric and vacuum distillations, the heavier hydrocarbon chains present in the crude oil must undergo additional cracking and distillation and then be broken up into shorter chains through various cracking and breaking processes. During these processes, analyzers can provide real-time data for plant technicians can make informed decisions on how to achieve the best yield from these residue products.

This information has been sourced, reviewed and adapted from materials provided by Process Insights – Optical Absorption Spectroscopy.

For more information on this source, please visit Process Insights – Optical Absorption Spectroscopy.