The yield stress of a sample is not a material constant but is very important in practical work. Many rheological methods have been developed to determine the yield stress.

What is the Yield Stress?

Substances with a yield stress only start to flow once the outside forces acting on them are larger than their internal structural forces. Below the yield point the substance shows elastic behavior (gel character). It behaves like a solid that reacts to load with a small deformation which completely regenerates when the load is removed. The material therefore behaves like a spring having a recoiling force which is proportional to the deflection. When shear forces are increased, the yield stress can be overcome so that irreversible deformations are present and the sample starts to flow.

The reason for the yield stress are intra-molecular interactions which cause a three-dimensional network of forces that give the substance a certain structural strength. This network of forces is destroyed when the yield point is overcome.

Why is the Yield Stress Important?

The yield stress is an important parameter for many practical issues and applications. It is used to characterize the dispersion and gel stability or the pumping behavior during filling processes.

The yield stress is not a material constant and depends on the measuring as well as the analysis method used. Therefore, it is essential to carry out the rheological measurements always under the same defined measurement and analysis conditions because this is the only way that results from different samples can be compared.

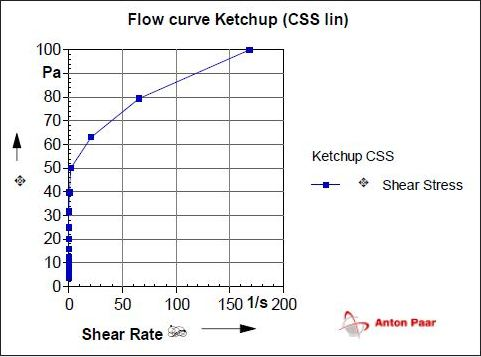

Figure 1. Linear representation of a flow curve (CSS setting) for determining the yield stress via the cross-over point on the y-axis.

Want to know more? Click here to read the full article.

Want to know more? Click here to read the full article.

.jpg)

This information has been sourced, reviewed and adapted from materials provided by Anton Paar GmbH.

For more information on this source, please visit Anton Paar GmbH.