Today I would like to discuss the importance and influence of sample preparation in the field of rheometry and give you some tips about how to prepare sensitive samples so that the results are correct and reproducible.

Sample preparation includes removing the sample from the container, shaking or stirring it, filling it into the measuring system, positioning the measuring system as well as the subsequent waiting time or a pre-defined shear before starting the actual measurement.

Depending on the properties of the sample, these preparatory steps have a considerable influence on the results of the rheological measurement. Therefore, sample preparation should always be carried out in the same way every time. This improves the reproducibility of your measuring data, even when many different people operate the rheometer.

Generally, sample preparation has little influence on measurements at shear rates over 10 1/s. However, sample preparation is particularly important when you are measuring at low shear rates or in oscillatory mode, i.e. when investigating the structure at rest to evaluate the stability of the sample. For these reasons, I will discuss each step of the sample preparation process in detail below.

Shaking and Stirring

Both shaking or stirring a sample puts it under a considerable and undefined shear load. Therefore, they should be avoided if possible. However, samples which separate or sediment must be shaken or stirred in order to perform correct measurements.

Shaking or stirring should be carried out in the same way every time, e.g. using the same tools and for the same amount of time. When measuring PVC plastisols, for example, you should first remove the top layer as this is where the plasticizer often collects or the sample may be dried out on the surface.

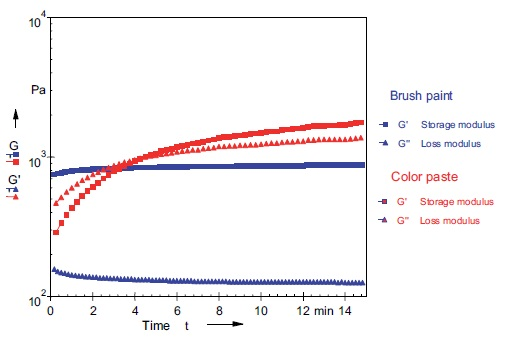

Figure 1. Structural regeneration after the application of paint.

Want to know more? Click here to read the full article.

Want to know more? Click here to read the full article.

.jpg)

This information has been sourced, reviewed and adapted from materials provided by Anton Paar GmbH.

For more information on this source, please visit Anton Paar GmbH.