There are many specific instances where these parameters are required as quality control indicators and therefore are required to be measured. In the bakery industry, for example, loaf volume is the principal component of and is of paramount importance too, bread quality evaluation. This is a vital aspect of the consumer’s perception of value because in bread and other leavened goods, higher volume – for the same weight – is invariably associated with more aerated crumb and superior texture.

For a baker or bread manufacturer, each batch of flour has to be evaluated by test baking to ensure that bread is made to a uniformly high quality. One component of this quality control is a measurement of the volume of the bread, which can give information relating to the density of the bread crumb and the strength of the gluten in the flour. Lack of volume generally indicates the use of weak flour or one low in enzyme activity.

A very strong flour may also produce a loaf of small volume, which would indicate the need for a longer fermentation period during which the gluten would become ripened and so more extensible. This volume information can then be used to modify the dough mix used in bread production, in order to produce bread of the appropriate quality. This procedure is important, not only for the inherent qualities of the bread, but to ensure that the selected dough-piece weight produces a loaf of the correct size for the standard tins used in the baking process.

The baked product must also be capable of being handled by automatic slicing machines and packed into standard sized bags. It is therefore important to have a precise and rapid method for the measurement of the volume of bread loaves, enabling control and monitoring of bread-making conditions and manufacturing operations.

Not only is Volume critical to bakery products, but it is also an important physical property of agricultural products, meats and packaging. Agricultural products have the characteristic of being ‘low value-added’ when compared with other industrial commodities. As a result, the application of state-of-the-art technology to the agricultural sector has been slow; it is only in relatively recent times that various up-to-date techniques have reached the point of practical implementation.

Previous volume methods may have involved simple water displacement; however, this method produces one volume value which is usually manually recorded and thereby attracts operator inaccuracy with no data archiving system for future retrieval. Fluid displacement techniques are also unsuitable for porous materials.

The Volscan Profiler – allows measurement, analysis, and comparison

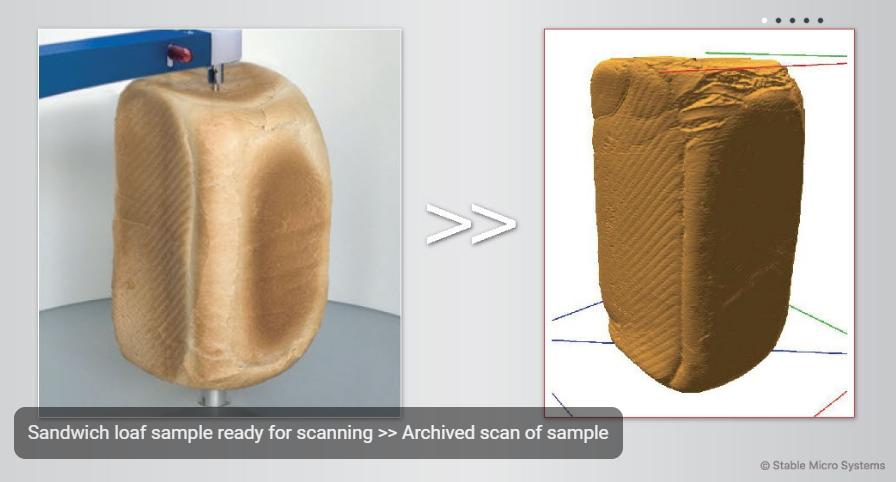

The Volscan Profiler is a benchtop laser-based scanner that measures the volume, density, and dimensional profiles of samples with maximum dimensions of 600mm long and 380mm diameter, with a typical test time of fewer than 60 seconds.

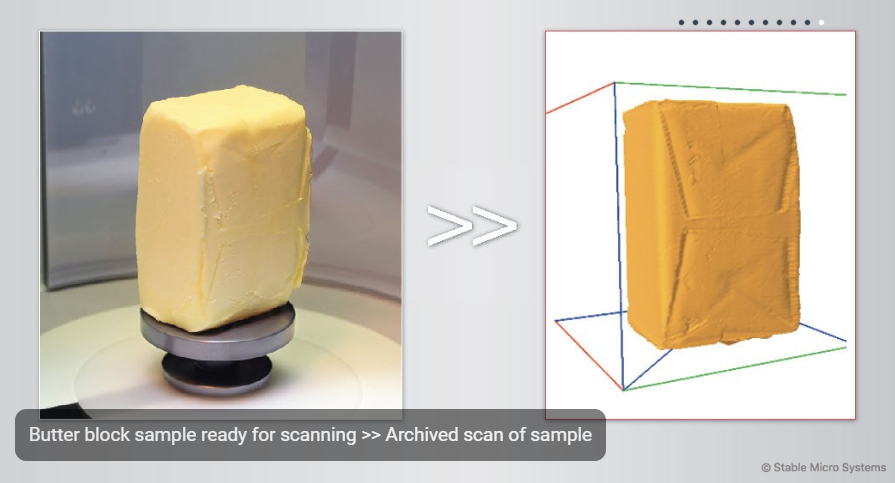

Instead of just assessing the volume as with seed or water displacement methods, the Volscan Profiler has the ability to automatically measure and calculate an additional 19 related parameters, such as height, width, length, and weight. It also enables the rapid 3-dimensional digitization of products which can be archived and then treated mathematically to yield detailed dimensional information for immediate use or future retrieval.

This instrument quickly provides accurate data essential in the fields of both Quality Control and Product Development.

Things you couldn't test using seed or water displacement...

Traditionally, volume measurements of baked products have been obtained by the technique of seed displacement, in which the amount of rapeseed or pearl barley packing around the loaf in a standard container is measured.

Whilst this method has been universally recognized for decades as indicative of baking quality, it is now considered primitive, inaccurate, tedious, and laborious. Repeated calibration, operator dependence, loss of rapeseed due to spillage/adherence of seeds to the product or to static electricity, seed clumping due to moisture absorption, periodic sieving of the seed to remove food crumbs, the potential crushing of soft products and the manual recording of results are the common drawbacks affecting both the efficiency and the accuracy of the measurement.

Besides offering rapid 3-dimensional digitization of products, it has the ability to measure objects that, due to their texture or size, were not possible with seed displacement. Soft, thin, or brittle products with vulnerable structure due to toppings, or being easily altered by the compressive nature of seed displacement are easily mounted on the Volscan Profiler by a variety of supporting pins.

The Volscan Profiler is also not affected porosity as would be the case when using traditional liquid displacement techniques.

When you want more than just volume measurement

Laboratory time is valuable, so operators will be keen to get the quickest and most comprehensive measurements from any testing that they perform, rather than piece together a series of measurements from several different instruments.

With the movement into digital measuring systems, manual procedures like a seed or liquid displacement that offer the measurement of one parameter can be replaced by procedures that offer not only a wider range of direct measurement parameters but also the ability to manipulate these parameters into additional measurements offering a wider scope of decision-making tools regarding the product’s quality.

Typical digital volume measurement includes the measurement of product length, height, and width – after all, the volume is a derivation of these dimensions. With the use of a loadcell as standard in the instrument, additional basic measurements of weight and Specific Volume, which are also of interest, are included. What if there were a whole host of additional optional calculations and parameters that could be collected simultaneously and automatically? For every product scanned the following information is automatically calculated and displayed alongside the 2D and 3D scans:

Weight, Specific Volume, Volume Yield, Product Density, Length, Surface Area, Max Height, Width at Max Height, Aspect Ratio at Max. Height, Max Width, Height at Max. Width, Aspect Ratio at Max Width, Height of Middle Slice, Width of Middle Slice, Aspect Ratio of Middle Slice, Minimum Enclosing Circle, Max Inclusive Square Volume, Trim Percentage, Circumference.

In a fast-paced food industry, rapid product measurement and provision of automatically calculated quality control pass or fail benchmarks is key to manufacturing intelligence and success.

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.