An international sensors leader collaborates with a custom cold forming manufacturer in order to supply a unique micro-miniature part for use in an environmental application in the automotive market.

Challenge

A worldwide sensors manufacturing and engineering company with headquarters in the U.S. faced a NPD challenge on a critical electronic connector component. It needed design, manufacturing and five sigma process capabilities to create a micro-electrical mechanical system (MEMS) for an automotive clean energy emissions application.

Furthermore, in order to supply its global assembly operations in Asia, the company needed 100% quality inspection and JIT inventory management.

Solution

They partnered with Sussex Wire, Inc., a custom cold forging specialist based in Easton PA, as the sensor company did not have the micro-machining and cold-heading services in-house to manufacture the parts needed for their assembly.

In order to meet the tolerance specifications, Sussex Wire developed the component geometry design, implemented 100% in-process automated optical inspection (AOI), plated, cleaned, and integrated the final assembly, packaging, and logistics to produce a complete solution.

Image Credit: Sussex Wire

As seen in Figure #1, a miniature wire bond pin component which was the result of this collaboration was designed and created from Copper CDA 102 with control dimensional tolerances down to +/- .00078 ”, a minor OD of .03937 ” and overall length of .2118 ”.

As a manufacturer, the key considerations were focused on maintaining the native mechanical properties of the CDA 102 substrate while attaining an end condition finish of a Ra under five microns.

Sussex Wire’s cold heading design engineering and manufacturing technology met the surface finish, dimensional, mechanical strength and piece part price needs uniquely, to support a successful customer MEMS automotive emission sensor market launch.

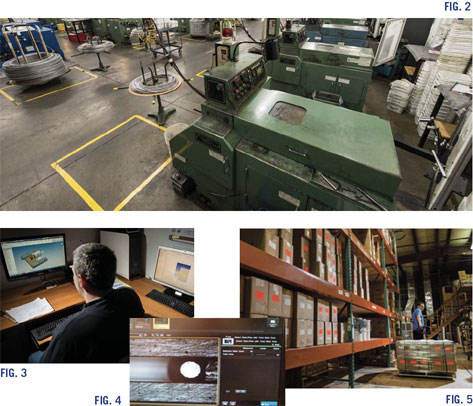

Through Sussex Wire’s proprietary part and tooling progression, vertically integrated manufacturing operations (Figure #2), incorporation of finite element analysis (Figure #3), and a proprietary Automated Optical Inspection (AOI) system developed and implemented by Sussex Wire (Figure #4), achieving and controlling a surface finish condition of a Ra of under five microns on the wirebond end was possible.

Image Credit: Sussex Wire

Result

Executed via an MRP supported Pull Kanban inventory system, the customer receives JIT delivery to their Asia Pacific contract assembly operation, as seen in Figure #5.

Key Features

Benefits for automotive companies looking to source custom metal parts from manufacturers such as Sussex Wire can include:

- Custom, in-process automated optical inspection system

- Lean JIT Kanban pull inventory management

- Competencies on collaborative engineering feasibility, project management and validation

- Application of cold heading manufacturing technology which preserves the native material's mechanical properties, even at high production velocity

- Vertically integrated tool and part design, and high volume production

This information has been sourced, reviewed and adapted from materials provided by Sussex Wire Inc.

For more information on this source, please visit Sussex Wire Inc.