There is a wide range of products that use lithium-ion (Li-ion) batteries as they require a rechargeable power source; Li-ion batteries have minimal memory effect, resistance to self-discharge and high energy density.

. Image Credit: Freeman Technology

These attributes make them very well suited for use in aerospace and automotive applications, power tools and consumer electronics.

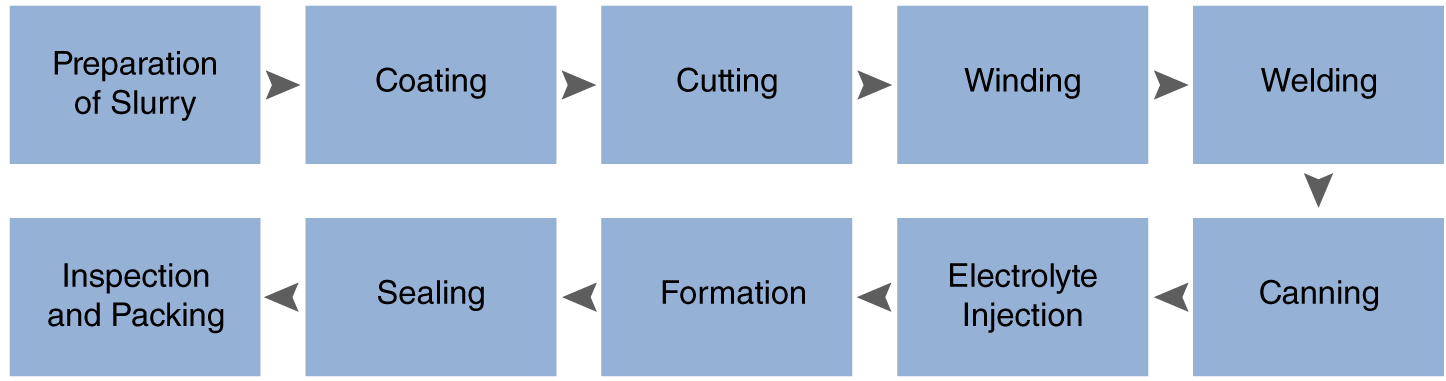

Figure 1 depicts a flow chart showing the usual process steps for producing Li-ion batteries.

The quality of the slurry produced at the start of the process significantly impacts each of the various stages within the process. The slurry’s properties are dependent on the properties of the binder and solvents mixed with the powder, along with how it behaves in the mixing process.

Figure 1. Typical Battery Production Process. Image Credit: Freeman Technology

The resulting slurry is required to meet critical criteria, such as solid content, viscosity and fineness of grain (FOG) to ensure a high-quality final product and optimal process performance.

How efficiently a slurry can coat a substrate is influenced by solid content uniformity, meaning that it is critical for the powder to be able to mix and disperse without agglomerating.

Process Relevant Powder Characterization

The rheological properties that determine flow behavior and influence factors, such as agglomeration, are the same ones that dictate how well a powder mixes and disperses to form a slurry.

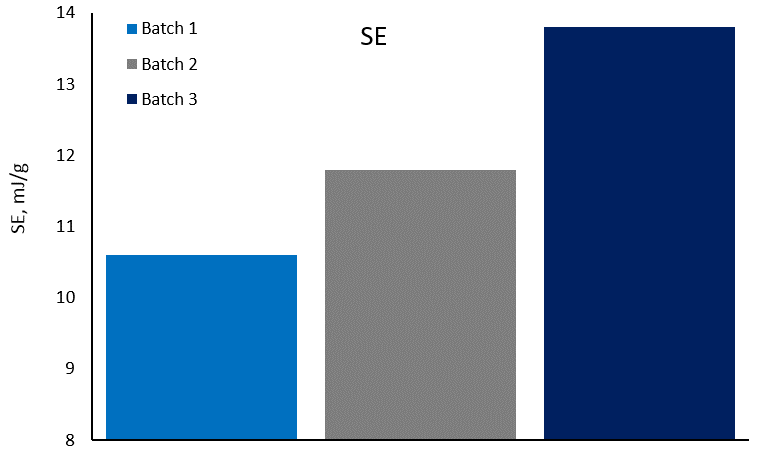

Figure 2. Specific Energy (SE) for 3 batches of LiFePO4 used in the production of Li-ion batteries. Image Credit: Freeman Technology

The data in Figure 2 demonstrates how properties in-process experience in the manufacture of Li-ion batteries correlate with those measured using the FT4 Powder Rheometer® (from Freeman Technology Ltd).

Cathodes were produced using three batches of LiFePO4 from different suppliers. The slurry used in batch 1 was known to produce a homogeneous slurry, while batches 2 and 3 were more inconsistent and additionally resulted in blockages leading to out-of-specification products and system downtime.

The degree of mechanical interlocking and friction between particles is quantified by SE. Batch 1’s low SE suggests that the particles are less likely to bind together to form agglomerates because they can disperse more freely.

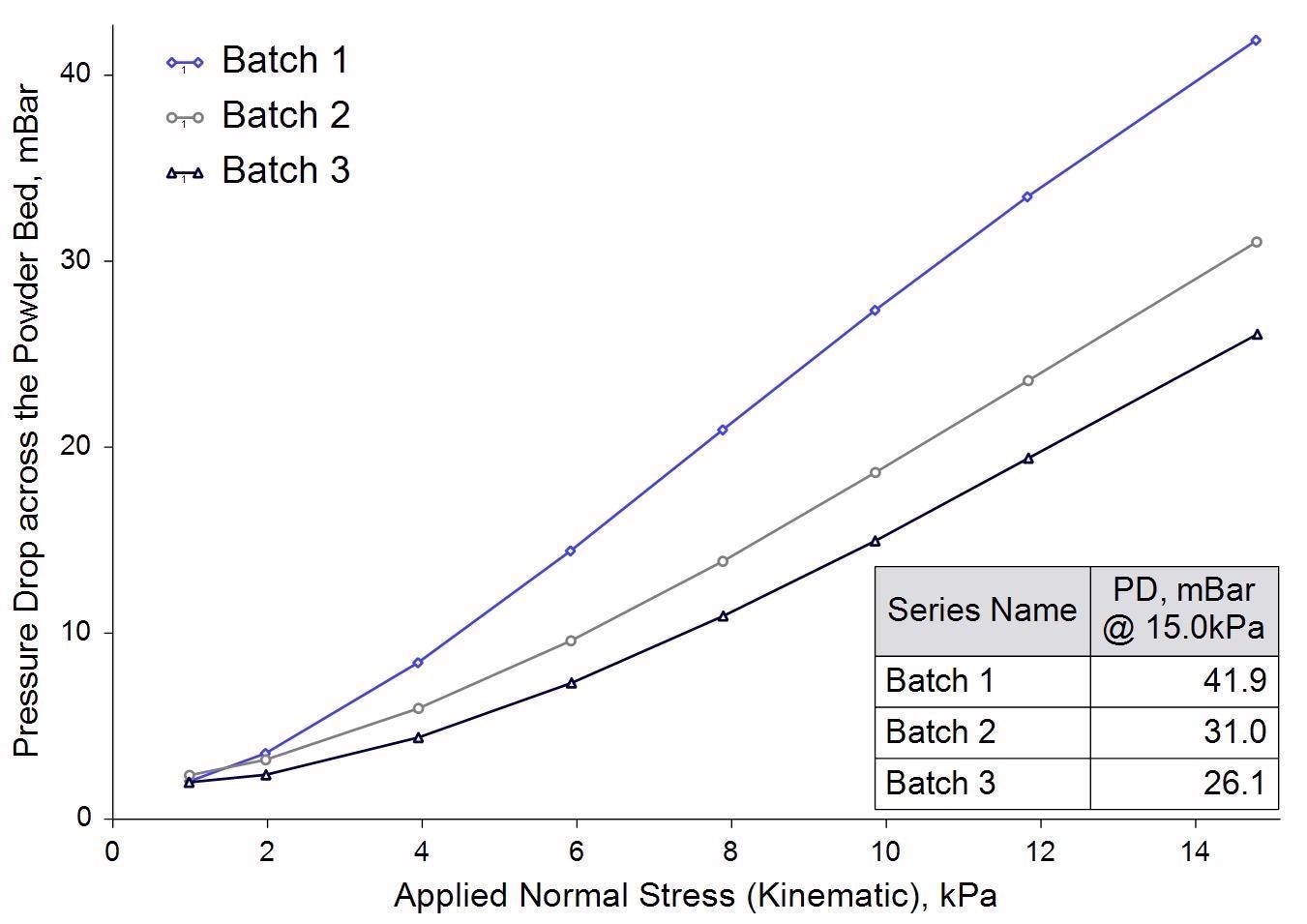

The ability of a powder to release or retain entrained air is known as permeability. Batch 1 recorded a higher pressure drop, which indicates lower permeability; this is likely caused by a more efficiently packed bed.

Powders showing more regular packing structures are able to disperse more uniformly and freely because they are typically more free-flowing. There is also a lower risk of agglomeration because of the lower cohesion strength.

Figure 3. Permeability (expressed as a Pressure Drop) for 3 batches of LiFePO4 used in the production of Li-ion batteries. Image Credit: Freeman Technology

The results imply that less permeable powders, with a low friction and low degree mechanical interlocking, are conducive to producing a homogeneous slurry that can be used in manufacturing electrodes to produce Li-ion batteries.

The FT4 Powder Rheometer’s multivariate approach enables the accurate quantification of these properties, allowing users to define robust powder specifications.

This information has been sourced, reviewed and adapted from materials provided by Freeman Technology.

For more information on this source, please visit Freeman Technology.