The aerospace industry is one of the major flourishing industries of the world, with the number of airplane passengers increasing manyfold in recent years. However, the major problem associated with the aerospace industry is the emissions and the pollution it causes.

Image Credit: Patrick Daxenbichler/Shutterstock.com

Being one of the most difficult industries to decarbonize owing to technical difficulties, the future of the aerospace industry is in grave danger if no substantial steps are taken in this regard. This is the major reason that researchers and major aerospace manufacturers and companies all over the world are attempting to reduce carbon emissions and pollution caused by the aerospace industry in an attempt to preserve the environment.

Aviation Emission Trends and Studies

Technological developments in all areas of life, including the aerospace sector, resulted in quicker and more efficient aircraft. However, as with other breakthroughs, this came at the expense of additional toxic emissions in the environment. By 1960, there were 100 million aviation passengers, and by 2017, the figure had risen to 4 billion worldwide. This massive increase in consumers led to a substantial increment in aviation emissions.

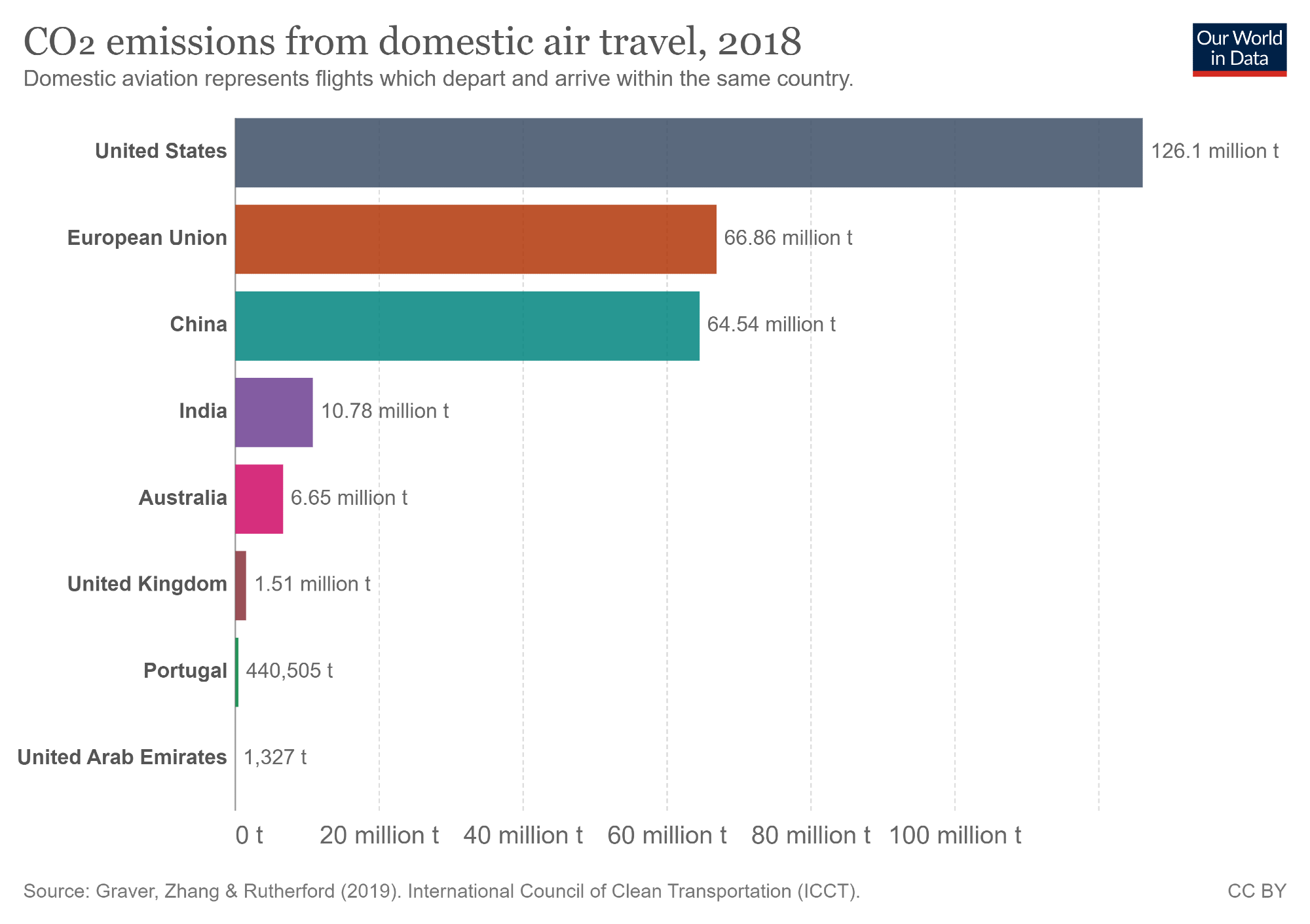

In 2018, the aerospace and aviation industry was held accountable for 2.4 percent of global CO2 emissions. Based on present trends, it was predicted that by 2050, commercial aviation aircraft emissions will have more than quadrupled. CO2, NOX (Nitrous gases), Sulphates, O3, and other hazardous pollutants contribute significantly to the surge in emissions all over the world in recent years.

Studies estimate that aerospace emissions would be responsible for about 22% of global emissions by 2050. These figures are alarming and could prove to be a fatal blow leading to global sanctions on the utilization of aerospace and aviation technologies. This would not only lead to a massive economical breakdown but also affect other various industries too. Hence, decarbonization is an unavoidable necessity.

Types of Aerospace Emissions

Aerospace experts all over the world classify emissions into three types: Scope 1, Scope 2, and Scope 3 emissions. Scope 1 emissions are generally referred to as the manufacturing process emissions and could readily be reduced by the organization responsible for the processes.

Further Reading on AZoM: Considering Renewable Hydrogen Production

The indirect emissions are included in Scope 2 emissions and are due to other factors incorporated in the manufacturing processes that might have caused significant carbon emissions during their synthesis. The most critical is the emission of Scope 3 which makes up about 70% of the total aerospace sector emissions.

These emissions are rendered when the manufactured aerospace assembly and systems comprising of various components operate. Such emissions are not controlled by the manufacturing organization and researchers all over the world have made these types of emissions the center of research for a significant cut in their overall value.

Essential Decarbonization Steps

Considering the concept of “Green Aviation and Aerospace sector” valid steps are been taken all over the world in almost every department of the industry to ensure a reduction in emissions.

These include the introduction of Sustainable Aviation Fuels (SAF), Electric Aircraft Propulsion, Innovative airplane design to reduce emissions, Novel Propulsion systems to diminish emissions, efficient traffic management, and fabricating sustainable environmentally-friendly supporting infrastructure. The major breakthroughs are sustainable aviation fuel and electric aircraft.

Image Credit: Our World in Data

Sustainable Aviation Fuel (SAF)

SAF is made from renewable biomasses and has a chemistry that is quite comparable to standard conventional aviation fuel. Employing SAF reduces greenhouse gas emissions relative to conventional aviation fuel. Cooking oil and other non-palm oils from living organisms are common renewable sources, as are waste materials from residences and companies, such as packing, paper, fabrics, and discarded food that would otherwise go to landfill or cremation.

These SAF from biological sources are bio-SAFs, while others from synthetic kerosene are synthetic-SAF. Since these involve sustainable constituents, neither the synthesis of their components nor their burning causes much pollution or produces emissions comparable to traditional fuel.

Electric Aircraft Systems

The most effective method that has been found to reduce emissions significantly has been the utilization of an electric propulsion system. Many problems are seen in hydrodynamics, and mechanical systems do not exist in carefully manufactured electrical power systems. Electronic systems are more versatile, compact, and economical. All of this is achievable while emitting zero hazardous emissions, benefiting not just the ecosystem but also the aerospace industry's economic stability.

Other Advantageous Steps

Although the above-mentioned steps are the major ones, many other steps could also be beneficial in this regard. Technologies such as hydrogen propulsion systems have also been tested and are successful in operating with almost no emissions. An up-gradation of air traffic framework rules and regulations to enable efficient air traffic flow with minimum disruptions and lesser distances would also prove to be fruitful in the reduction of such emissions.

Sustainable Infrastructure such as sustainable energy for aerospace industrial operations, solar-powered components, and procurement of zero-emission ground support equipment would also be major advances towards sustainable and green aviation.

Limitations of Decarbonization Strategies

Although the study of decarbonization strategies has depicted their advantages, certain limitations exist in their wide-scale applications. The SAF is very advantageous, yet its cost is so high that it is almost impossible to implement for worldwide aviation purposes. Along with this, owing to its properties, new mechanisms for its storing and distribution are required which is a very major challenge.

The electric propulsion system, although it seems like a perfect choice, has challenges associated with its implementation that are great. To properly implement an electric propulsion system, design changes such as engine mount changes are required, which is a lengthy and expensive process.

Along with this, the batteries are quite heavy, increasing the weight of the aircraft and causing a significant decrease in its overall performance. These features only make it suitable for low altitude small flights.

In short, the aerospace industry needs to focus on the problem of emissions, as it is becoming the major source of harmful environmental emissions. Although a few strategies have been proposed, even more study and research is required for not only the sustainable implementation of such techniques but also the development of novel emission-free techniques.

References

Apostolidis, A. (2021, April). Decarbonizing by 2050: Optimists, pessimists and realists. From Aerospace America: https://aerospaceamerica.aiaa.org/departments/decarbonizing-by-2050-optimists-pessimists-and-realists/

Deloitte. (2021). Decorbonizing Aerospace. From deloitte: https://www2.deloitte.com/uk/en/insights/industry/aerospace-defense/decarbonizing-aerospace.html

Liu, Y., Sun, X., Sethi, V., Nalianda, D., Li, G. Y., & Wang, L. (2017). Review of modern low emissions combustion technologies for aero gas turbine engines. Progress in Aerospace Sciences, 12- 45. https://dspace.lib.cranfield.ac.uk/handle/1826/12499

Ng, K. S., Farooq, D., & Yang, A. (2021). Global biorenewable development strategies for sustainable aviation fuel production. Renewable and Sustainable Energy Reviews. https://www.sciencedirect.com/science/article/pii/S1364032121007814

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.