The variation in particle size of mineral pigments leads to differences in hiding power, primarily attributed to the phenomenon of light scattering. This phenomenon contributes to smoother color transitions and richer chromatic gradation of pigments.

The research employs the Bettersizer 2600 particle size analyzer to detect and control this physical effect. This article presents a method for measuring particle size to optimize pigment formulations and achieve desired color effects in various fields.

Secret Behind Particle Sizing of Mineral Pigment

Video credit: Bettersize Instruments

Introduction

Hiding power, also known as hiding strength or coverage, refers to the capacity of a coating or pigment to conceal the underlying surface or previous layers, effectively obscuring the color or pattern of the substrate.

It holds significant importance in various industries, particularly in paint, coatings, and printing, as it determines the coating's efficiency in achieving the desired color and appearance while masking imperfections and inconsistencies on the surface.

Manufacturers and consumers prioritize coatings with higher hiding power due to their ability to provide optimal coverage, leading to a satisfactory outcome. The hiding power of mineral pigment is directly linked to the particle size of the pigment particles. Generally, smaller particle sizes result in improved hiding power.

Smaller particles can effectively fill fine imperfections and surface unevenness, resulting in a smoother and more uniform coating. Moreover, smaller particles enhance paint’s hiding power by promoting a stronger scattering effect of light on the particle surface.

This increased scattering and reflection of light reduce the likelihood of light penetrating through the coating, leading to enhanced hiding strength, color consistency, and seamless chromatic gradation of the pigment.

Materials and Methods

The primary objective of this experiment is to investigate how the particle size of mineral paint influences its hiding power. The article utilizes the Bettersizer 2600 to measure the particle size distribution of the pigments.

The Bettersizer 2600 employs the laser diffraction method, which allows precise and efficient characterization of particle sizes in diverse industries and research fields by analyzing the scattering pattern of laser light. The materials utilized in this study include raw coral reef and lazurite.

The experiment controls different grinding times to achieve varying particle size distributions, resulting in several pigment samples with different particle sizes.

To determine the hiding power of these pigment samples, the standard method specified in ASTM D6441-05 is employed. This method helps establish the relationship between the mineral pigment's coverage and particle size.

Bettersizer 2600. Image Credit: Bettersize Instruments Ltd

Result and Discussion

Grinding Result

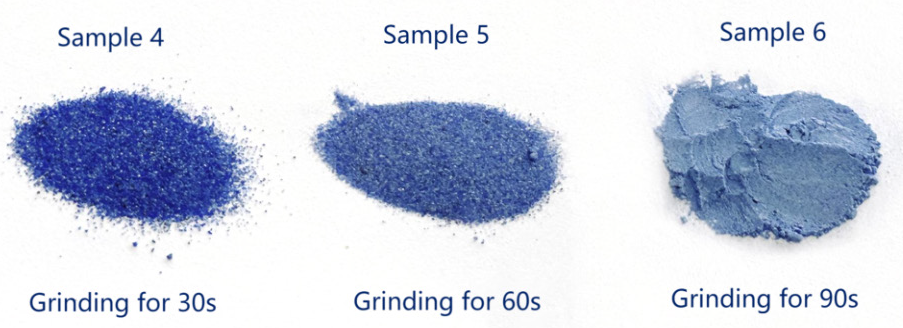

The outcomes of the experiment, involving raw coral reef and lazurite with varying grinding times, are depicted in Figures 1, 2, and 3. Adjusting the grinding time gives a range of samples with distinct particle size distributions. Notably, as the grinding time increases, the particle size of the samples decreases, resulting in noticeable changes in their color characteristics.

In particular, Figure 2 presents three coral reef samples obtained from the same initial sample but differing only in grinding time. It is evident that Sample 1, ground efficiently for 30 seconds, exhibits the coarsest particles with the highest color saturation but the lowest brightness.

Conversely, Sample 3, ground for 90 seconds, displays the finest particles with the lowest color saturation but the highest brightness. The outcomes seen in the case of lazurite, as shown in Figure 3, support similar findings.

Figure 1. Coral reef and Lazurite grinding for 0 second. Image Credit: Bettersize Instruments Ltd

Figure 2. Grinding samples of coral reef for 30 seconds, 60 seconds, 90 seconds. Image Credit: Bettersize Instruments Ltd

Figure 3. Grinding samples of lazurite for 30 seconds, 60 seconds, 90 seconds. Image Credit: Bettersize Instruments Ltd

Particle Size Result

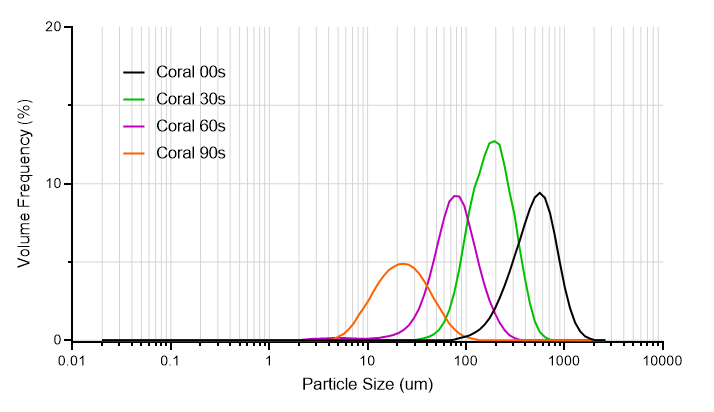

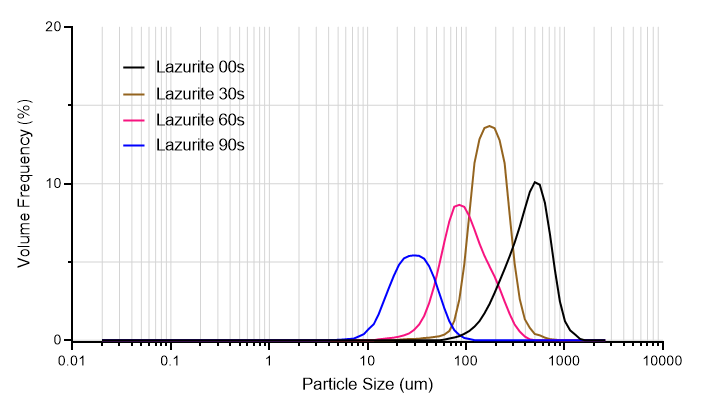

Figure 4 and Figure 5 provide the particle size distribution of ground coral reef and lazurite, each for 0 seconds, 30 seconds, 60 seconds, and 90 seconds. The particle size distribution of these two mineral pigments shows a very similar trend which can also be observed in Table 1 and Table 2.

Figure 4. Particle size distribution of ground coral reef for 0s, 30s, 60s, and 90s. Image Credit: Bettersize Instruments Ltd

Table 1. Typical particle size values of three coral samples. Source: Bettersize Instruments Ltd.

| Sample |

Dv10(µm) |

Dv50(µm) |

Dv90(µm) |

| Coral 00s |

221.8 |

473.2 |

841.8 |

| Coral 30s |

101.9 |

177.6 |

301.4 |

| Coral 60s |

34.47 |

72.43 |

137.3 |

| Coral 90s |

7.674 |

21.33 |

73.38 |

Figure 5.Particle size distribution of ground lazurite for 0s, 30s, 60s, and 90s. Image Credit: Bettersize Instruments Ltd

Table 2. Typical particle size values of three lazurite samples. Source: Bettersize Instruments Ltd.

| Sample |

Dv10(µm) |

Dv50(µm) |

Dv90(µm) |

| Lazurite 00s |

189.2 |

413.7 |

689.1 |

| Lazurite 30s |

106.3 |

161.6 |

239.8 |

| Lazurite 60s |

46.76 |

89.58 |

196.3 |

| Lazurite 90s |

13.08 |

28.61 |

53.75 |

Hiding Power Result

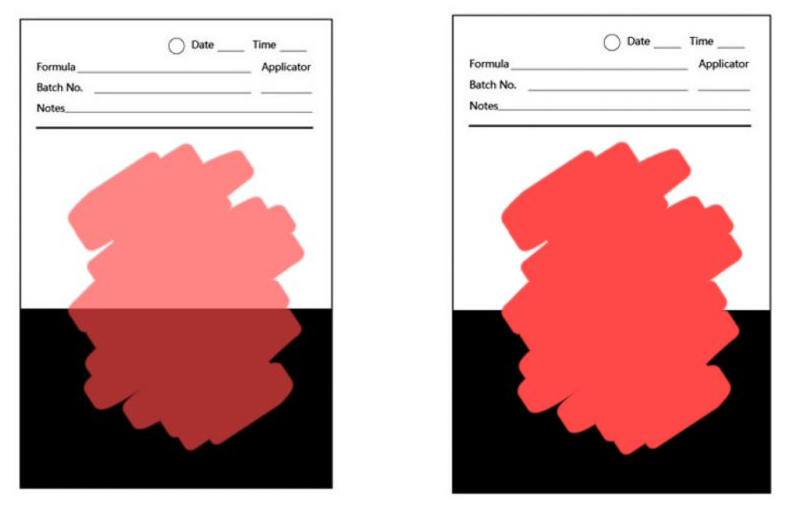

The hiding power of the pigment samples, which refers to the pigment's ability to conceal the underlying substrate effectively, is assessed using the standard method outlined in ASTM D6441-05.

In this method, the pigment is applied to smooth, glossy test panels divided into black and white areas with a clear boundary. This allows visual evaluation of pigment coverage, as illustrated in Figure 6. To obtain accurate percentages, a testing instrument is necessary to measure the hiding power of the samples.

Figure 6. Example of Hiding power 50% vs. 100%. Image Credit: Bettersize Instruments Ltd

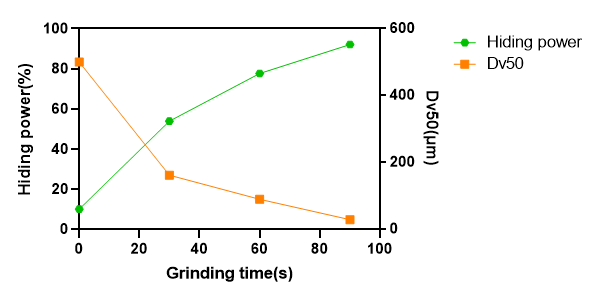

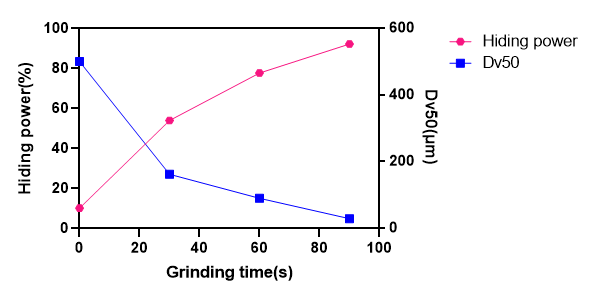

The correlation curves in Figures 7 and 8 illustrate the relationship between hiding power, median particle size Dv50, and grinding time for coral and lazurite. Mineral pigments composed of coarse particles generally exhibit higher color saturation and lower lightness, resulting in weaker hiding strength.

In contrast, fine particle pigments, owing to their smaller size, can fill the paint surface more effectively, leading to a more uniform color and stronger hiding strength.

The trends observed in these graphs lead to the conclusion that once the particle size reaches a specific small value, the hiding power approaches 100%, indicating that further grinding cannot significantly alter the coverage exhibited by the pigment.

Utilizing the Bettersizer 2600 allows the determination of this critical particle size threshold, avoiding unnecessary grinding in industrial processes and reducing milling costs.

Figure 7.Correlation curves between hiding power, Dv50, and grinding time for coral. Image Credit: Bettersize Instruments Ltd

Figure 8. Correlation curves between hiding power, Dv50, and grinding time for lazurite. Image Credit: Bettersize Instruments Ltd

Through a comparative analysis of the results from both mineral samples, rather than focusing solely on one pigment, this experiment validates the universality of the impact of particle size on hiding power across different types of minerals.

This association is not limited to specific mineral types but holds broader applicability, further enhancing the understanding of this correlation. For various mineral materials, distinct particle size ranges demonstrate corresponding hiding strengths.

Consequently, the Bettersizer 2600 offers meticulous granularity measurement and supports identifying an optimal balance between particle size and desired coverage, ensuring consistency in the final products.

Conclusion

The Bettersizer 2600 particle size analyzer is a highly reliable and precise instrument for measuring mineral pigment particle sizes. This article delves into a comprehensive investigation of the correlation between the particle size of mineral pigments and their hiding power, along with the chromatic gradation of their color.

The insights gained from this study can be of immense assistance to customers in various industries, including coatings, pigments, paints, and related fields, ultimately leading to enhanced coatings with meticulous control in the manufacturing and production processes.

This information has been sourced, reviewed and adapted from materials provided by Bettersize Instruments Ltd.

For more information on this source, please visit Bettersize Instruments Ltd.