The excessive reliance on traditional energy sources like coal, oil, and natural gas fossil fuels has resulted in a massive increase in the emission of greenhouse gases and climate-related challenges, leading to environmental crises. This difficulty emphasizes the pressing need for sustainable energy alternatives characterized by superior efficiency and adaptability. Recently, renewable energy resources have emerged as a pivotal solution in limiting the dependency on fossil fuels and mitigating their adverse environmental impacts. Within this domain, membrane-based fuel cells have gathered significant attention, primarily due to their favorable and advantageous properties.

Image Credit: PixelSquid3d/Shutterstock.com

The Significance of Fuel Cell Technology

Fuel cells are an advanced, dependable, and highly efficient technological development, adept at converting chemical energy into economical and eco-friendly electrical power through electrochemical reactions. Among the various types of fuel cells, solid-oxide fuel cells (SOFCs) emerge as a notably robust and effective category and are the parent category of semiconductor membrane fuel cells. SOFCs have several advantages over their counterparts, including their capacity to utilize a wide range of fuels, higher power density, and reduced reliance on costly catalysts.

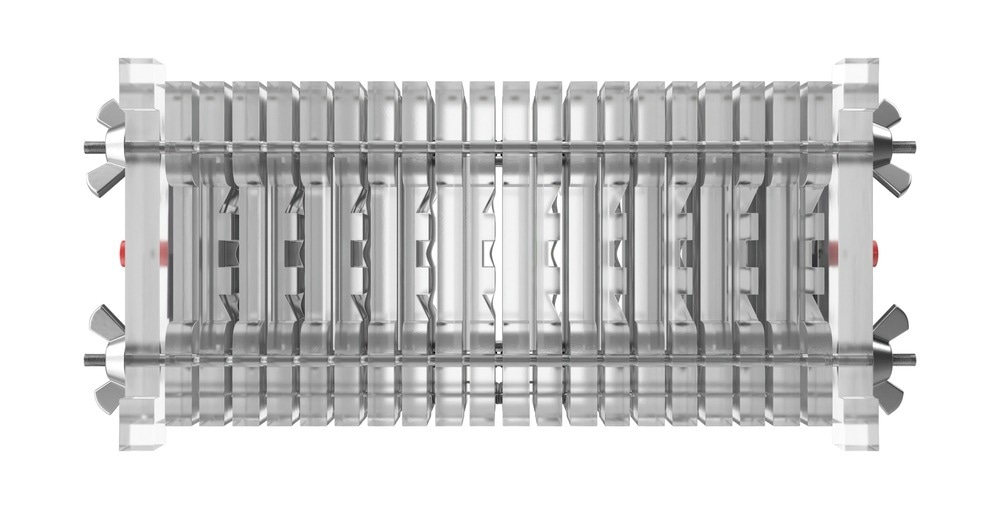

The fundamental structure of SOFCs consists of three principal components: electrodes (both anode and cathode) and an electrolyte, with the electrolyte sandwiched between two porous electrodes. The core principle governing the operation of SOFC devices hinges on the flow of oxide ions (O2−) through the intermediary electrolyte layer.

What are Semiconductor Membrane Fuel Cells

In a recent study published in the journal Energy Materials, researchers call semiconductor membrane fuel cells (SMFCs) a novel and much more efficient form of SOFCs. SMFCs exhibit a distinctive feature setting them apart from their conventional counterparts, characterized by their elimination of physically separated electrolyte layers and the inclusion of hydrogen oxidation reaction (HOR) and oxygen reduction reaction (ORR) at the anode and cathode. This innovative type of fuel cell design is constructed using a semiconductor membrane (SM) or Solid Ionic Membrane (SIM), enabling the execution of both the fuel cell HOR and ORR within a single-layer configuration.

SMFCs primarily rely on this single layer of SM/SIM to facilitate nano-redox processes, enabling the completion of the fuel cell reaction. This approach significantly differs from that of conventional Solid Oxide Fuel Cells (SOFCs). The initial demonstration of such a device was accomplished using a homogeneous mixture of semiconducting oxides (NiO and ZnO) and ionic-conducting oxides (SDC or GDC). It was aptly called a "three-in-one" device since the single layer can simultaneously serve as an electrolyte for ion transport and as electrodes for HOR and ORR processes.

Origin of Semiconductor Membrane Fuel Cells

As per a recent article published in Renewable and Sustainable Energy Reviews, traditionally, the presence of electrolytes with partial electronic conductivity has been associated with a substantial reduction in fuel cell device efficiency and open-circuit voltage (OCV). In 1992, Riess pioneered the exploration of mixed conductors, which exhibited both ionic and electronic conduction properties. This innovation sought to enhance the power output efficiency of solid-oxide fuel cells (SOFCs).

Subsequent research studies investigated the use of semiconductor oxides, particularly those possessing comprehensive bandgap characteristics, as alternatives to the conventional ionic electrolyte layer in SOFC operation. This novel approach gave rise to designations such as single-layer fuel cells (SLFCs) and electrolyte-free fuel cells (EFFCs). These refer to a single layer of semiconductor-ionic hetero-structure composite material that can effectively replace the conventional three-layer configuration.

Importance of Semiconductor Ionic Hetero-Structure

In contrast to single-phase semiconductor membranes, which often fall short of achieving the objective of simultaneously improving ionic conductivity and enabling lower operational temperatures with enhanced open-circuit voltage (OCV), the utilization of hetero-structure semiconductors or composite hetero-structures, either combined with ionic conductors or other semiconductors, can yield superior performance. These hetero-structure configurations offer significantly higher ionic conductivity when compared to conventional electrolyte materials.

Technological Differences from Conventional Fuel Cells

Researchers have published a thorough study in iScience highlighting the technological differences in conventional SOFC and have mentioned the novel processing technology of semiconductor membrane fuel cells. According to the article, one effective approach for enhancing the performance of Solid Oxide Fuel Cells (SOFCs) at lower temperatures (<600 degrees Celsius) and thus reducing their operating temperature is the fabrication of thin-film electrolytes.

Several widely adopted techniques for this purpose include pulsed laser deposition (PLD), atomic layer deposition (ALD), and the sol-gel method. However, it's important to note that the process of fabricating thin-film electrolytes is costly and complex. Additionally, it raises concerns about long-term durability when compared to bulk electrolyte-supported SOFCs.

In contrast to SOFC thin-film technologies, which aim to shape the electrolyte ceramic layer to reduce internal resistance, advanced Membrane Fuel Cells (SMFCs) benefit from a simpler bulk-shaping technology. This is primarily due to the similarity of semiconductor materials used in the electrolyte membrane to an SOFC cathode component.

SMFCs do not face the challenging technical issue of addressing interfacial gaps between the SOFC electrolyte and electrode, a problem that contributes significantly to power loss in traditional SOFC technology.

Current Limitations

Currently, SMFCs are primarily in the research phase, facing limitations in terms of engineering and financial support for technical projects. These constraints have restricted the scope of data collection related to reviewing the technical and engineering challenges associated with SMFCs. Presently, these cells are being manufactured at a laboratory scale. However, from both material and technical perspectives, compatibility issues persist due to the absence of suitable electrode materials that exhibit strong chemical and mechanical compatibility with semiconductor-based membranes. It is widely acknowledged that significant technical and engineering challenges continue to obstruct the rapid scalability of this innovative SMFC technology.

Much research needs to be done for the efficient commercialization of semiconductor membrane fuel cells. The study of energy bands and policy support from governments worldwide will surely accelerate the industrial fabrication of these novel efficient renewable energy fuel cells.

More from AZoM: How is Calorimetric and Differential Thermal Analysis Used in Petroleum Chemistry?

References and Further Reading

Shah, M. et. al. (2023). Semiconductor-membrane fuel cell (SMFC) for renewable energy technology. Renewable and Sustainable Energy Reviews, 185, 113639. Available at: https://doi.org/10.1016/j.rser.2023.113639

Zhu, B. et. al. (2021). A nanoscale perspective on solid oxide and semiconductor membrane fuel cells: Materials and technology. Energy Mater, 1(1–13), 100002. Available at: https://doi.org/10.20517/energymater.2021.03

Hu, E. et. al. (2021). Junction and energy band on novel semiconductor-based fuel cells. Iscience, 24(3). Available at: https://doi.org/10.1016/j.isci.2021.102191

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.