MODEL 3541 fracture mechanics clip-on gages are compliant with standard test methods like ASTM E1820 for determining the fracture toughness characteristics of metallic materials.

These gages comply with E1820 requirements for R-curve and JIC curve determination. In order to satisfy the requirements of ASTM E399 for fracture toughness, special configurations are offered.

Furthermore, the modified groove design is in full compliance with E1820 tests where higher accuracy and stability is obtained from the sharper groove root.

Clip-on gages find applications in a range of fracture mechanics tests including arc shaped, disc shaped, compact tension, bend specimens or other specimen geometries that comply with ASTM and other standards organization’s test methods.

It is possible to directly use clip-on gages on test specimens when knife edges are integrated with the test specimen or with optional bolt-on knife edges mounted on the test specimen.

The Model 3541 extensometers are strain gaged devices, rendering them compatible with any electronics developed for strain gaged transducers. The extensometers are mostly connected to a test machine controller.

The extensometer’s signal conditioning electronics in normally included with the test machine controller or may be added. Here, the extensometer is supplied with suitable wiring and connector to enable direct plugging into the electronics.

Epsilon can offer a range of solutions for systems that lack the required electronics enabling connection of the extensometer output to chart recorders, data acquisition boards or other equipment.

Key Features

The key features of the MODEL 3541 clip-on gages include:

- Full bridge, 350ohm strain gaged design showing compatibility with nearly any test system

- The gages are completely enclosed in order to secure them from accidental damage

- All the standard units satisfy existing ASTM requirements for accuracy

- Special models are offered for ASTM E399 accuracy requirements.

- Sharp grooves complying to ASTM E1820 and E399 enable enhanced stability when mounted.

- High quality foam lined case is included

- Based on gage length, test requirements and test amplitude, there is a variation in the maximum test frequency (2-200 Hz)

- Minimum measuring ranges are suggested in cases where very high frequency is needed for dadN testing or pre-cracking.

- For JIC/KIC testing, with small measuring ranges and large gauge lengths, maximum test frequency is attained.

Epsilon MODEL 3541 Fracture Mechanics Clip-On Gages

Model 3541-004M-120M attached to bolt-on knife edges

Model 3541-004M-120M with 4 mm gauge length and +12/-2 mm measuring range

Model 3541 Available Versions

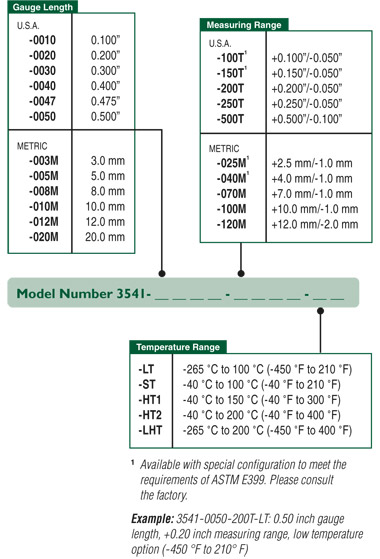

The following gauge length and measuring range combinations are available except as noted. All are available in the listed temperature ranges. Other configurations can be supplied based on customer requirements.

Optional Accessories

Options available include the following:

- Connectors for interfacing to almost any brand test equipment

- Available in special versions

- Severe environment versions are offered

- Bolt on knife edges