Epsilon Shunt Calibration System – Model ESCS

The Epsilon Shunt Calibration System is an option for any strain-gauged extensometer. It is designed to enable Epsilon’s extensometer calibration to be transferred easily to a customer’s electronics.

What is Shunt Calibration?

A simple way of calibrating an extensometer and signal conditioning electronics without the use of a mechanical calibrator is provided by the Epsilon Shunt Calibration System. With Shunt calibration, it is possible to perform on-site electrical calibration with almost all controller and electronics types. Shunt calibration also enables simple periodical “spot checking” of the electronics’ calibration. This helps to ensure the correct calibration of the extensometer and electronics.

It is worth noting that the need for using a mechanical extensometer calibrator for on-site verification is not replaced by the Epsilon Shunt Calibration System. Many labs and testing standards require on-site verification.

Which Extensometers Include the Epsilon Shunt Calibration System?

Every new Epsilon strain-gauged extensometer includes the Epsilon Shunt Calibration System. If customers wish for the Epsilon Shunt Calibration System to be added to an existing extensometer by Epsilon, they can send their extensometer to Epsilon for re-calibration.

In addition to installing the Epsilon Shunt Calibration System, Epsilon will perform a calibration and return the retrofitted extensometer with a new Epsilon Test Certificate.

How Does Shunt Calibration Work?

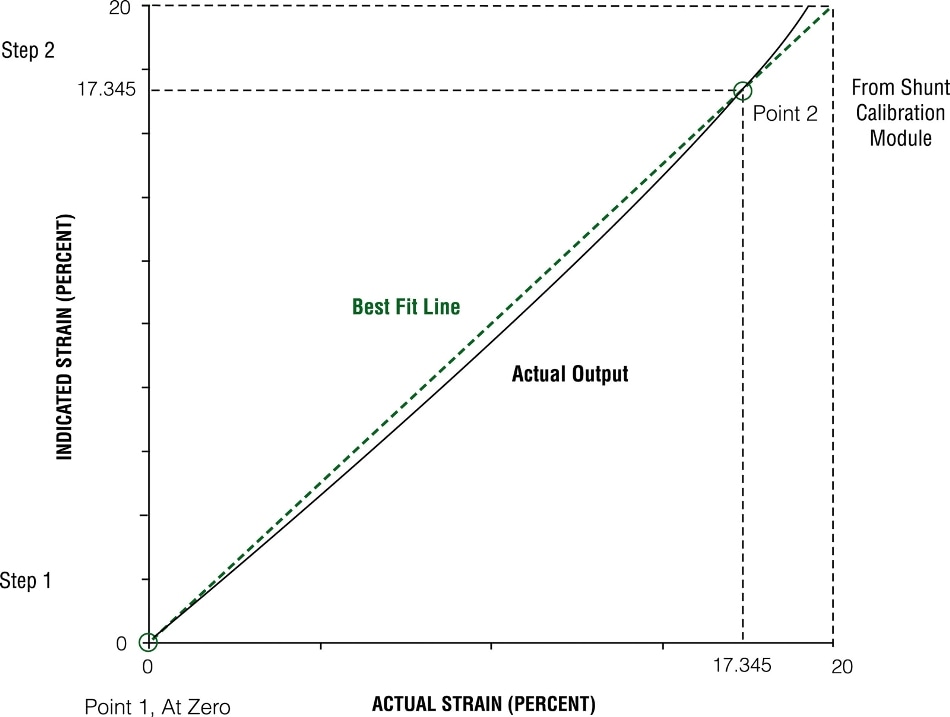

The Epsilon Shunt Calibration System is used for two-point calibrations.

The extensometer’s gauge-length is the first point.

The shunt calibration point is the second point. When the Epsilon Shunt is plugged into the Shunt Connector, the shunt resistor – situated in the Shunt Connector – is connected electronically across a single arm of the extensometer’s Wheatstone bridge.

As a result, the extensometer’s output is electrically set to a known calibration point without the need to mechanically displace the arms of the extensometer. The known calibration point appears on the Test Certificate of the extensometer as the Shunted reading, which was set at Epsilon with the use of traceable mechanical calibrators as well as an accredited ISO 17025 calibration process.

The signal conditioning or software are adjusted in order to complete the shunt calibration. This is so that the extensometer’s readout concurs with the Shunted Reading which is shown on the extensometer’s Test Certificate.

Using the Epsilon Shunt Calibration System is a Simple Two-Step Process

- Set the extensometer to its gauge length and zero the output. This sets point 1 in the example graph above.

- Plug the Epsilon Shunt into the Shunt Connector and adjust the signal conditioning electronics or software so that the extensometer’s readout concurs with the Shunted Reading on the Test Certificate of the extensometer. This sets point 2 in the example graph above.

That’s all it Takes.

This process applies to almost all combinations of strain-gauged extensometer and signal conditioning electronics or software. Even if the test controls have their own internal shunt calibration capability, this process works.

It is useful for analog controllers, digital test machine controllers, data acquisition systems and stand-alone extensometer signal conditioning electronics.

Furthermore, it is possible to periodically recalibrate the extensometer by sending the extensometer to Epsilon for recalibration service.