The ASAP 2020 Plus is a top-tier adsorption analyzer that measures surface area, pore size, and volume in powders and porous materials.

- High-resolution surface area and porosity analyzer

- Independent preparation and analysis instrument in a single cabinet

- Ideal for research, development, and quality control applications

The ASAP 2020 Plus is adaptable, allowing standard methods or personalized protocols to assess adsorbents, catalysts, zeolites, MOFs, APIs, excipients, and a broad range of porous and non-porous materials.

This analyzer excels in gas adsorption analysis of microporous (0.35 to 2 nm) and mesoporous (2 to 50 nm) materials, boasting unparalleled accuracy, resolution, and data handling capabilities. Moreover, an additional vapor sorption feature can be integrated to expand the physisorption analysis range of the ASAP 2020 Plus.

With the inclusion of a chemisorption option, the ASAP 2020 Plus widens its applications to encompass both physical and chemical adsorption. This functionality enables the comprehensive characterization of catalyst textures, active surfaces, catalyst supports, sensors, and various other materials.

Features and Benefits

Design Versatility

- Two separate vacuum systems allow for the processing of two samples while another is analyzed. This increases employee productivity and the client's return on investment.

- The innovative Isothermal Jacket Cold Zone Control and continuous saturation pressure (Po) monitoring provide a steady thermal environment for both saturation pressure and adsorption. Spend time on outcomes rather than temperature controls.

- The ASAP 2020 Plus can be configured with various accessories to match individual analytical needs.

Advanced Capabilities Through Optional Configurations

The ASAP 2020 Plus can be tailored to the exact demands, with the option of upgrading later if the analytical requirements evolve, increasing the value of this instrument and the investment.

Users can choose between low surface area, heated vapor, and micropore capabilities. When working with hostile vapors, add a cryostat or an external detector or modify the machine for increased chemical resistance. The ASAP 2020 Plus allows users to use a single instrument to meet practically any surface characterization requirement in the laboratory.

Adding a chemisorption option broadens the ASAP 2020 plus’s application range to include physical and chemical adsorption for assessing the texture and active surface of catalysts, catalyst supports, sensors, and other materials.

Unique and Innovative Isothermal Jacket Cold Zone Control

Isothermal jackets are guaranteed for the instrument's life and maintain a consistent thermal profile over the whole length of the sample and saturation pressure (Po) tubes.

Specifications

Analysis. Source: Micromeritics Instrument Corporation

| Analysis |

|

|

| |

Physisorption |

Chemisorption |

| Analysis Range |

1.3 x 10-9 to 1.0 P/P0 |

1 x 10-6 to 900 torr |

| Roughing Pump |

4 stage diaphragm |

4 stage diaphragm |

| Krypton Analysis |

optional |

standard |

| Minimum Measurable Surface Area |

Standard 0.01 m2 /g 0.01 m2 /g

Krypton 0.0005 m2 /g 0.0005 m2 /g |

|

| |

Physisorption |

Chemisorption |

| Adsorptive Gas Inlets |

6 |

12 standard; optional up to 16 |

| Vapor Sorption Option |

Included, optional heated vapor source |

Included, optional heated vapor source |

| Furnace |

N/A |

Ambient to 1100 °C |

| Programmable from 0.1 to 50 °C/min |

| Degas |

2 |

2 |

| Pressure Transducer System |

1000 torr 0.12% reading |

1000 torr 0.12% reading |

| Transducer Accuracy |

10 torr 0.12% reading |

10 torr 0.12% reading |

| 0.1 torr 0.15% reading |

0.1 torr 0.15% reading |

| Cryogen |

|

|

| |

Physisorption |

Chemisorption |

| Cryogen Dewar |

3.2 L, unlimited holding time with refill during analysis |

3.2 L, unlimited holding time with refill during analysis |

| Cryogen Free Space Control |

Isothermal Jacket |

Isothermal Jacket |

| Reports |

|

|

| Data Analysis for Texture and Active Area |

BET Surface Area, t-Plot, BJH, Horvath-Kawazoe, Saito-Foley, Cheng-Yang, DFT, NLFT, and others |

Metal dispersion, Metal surface area, Crystallite Size |

| Advanced Modeling |

Heat of Adsorption, GAB, Sips, Toth, dissociative Langmuir, Redlich-Peterson, Virial Equation, AutoFit BET |

| Instrument Operation Dashboard |

Dashboard permits real-time monitoring of critical parameters |

Technology and Configuration

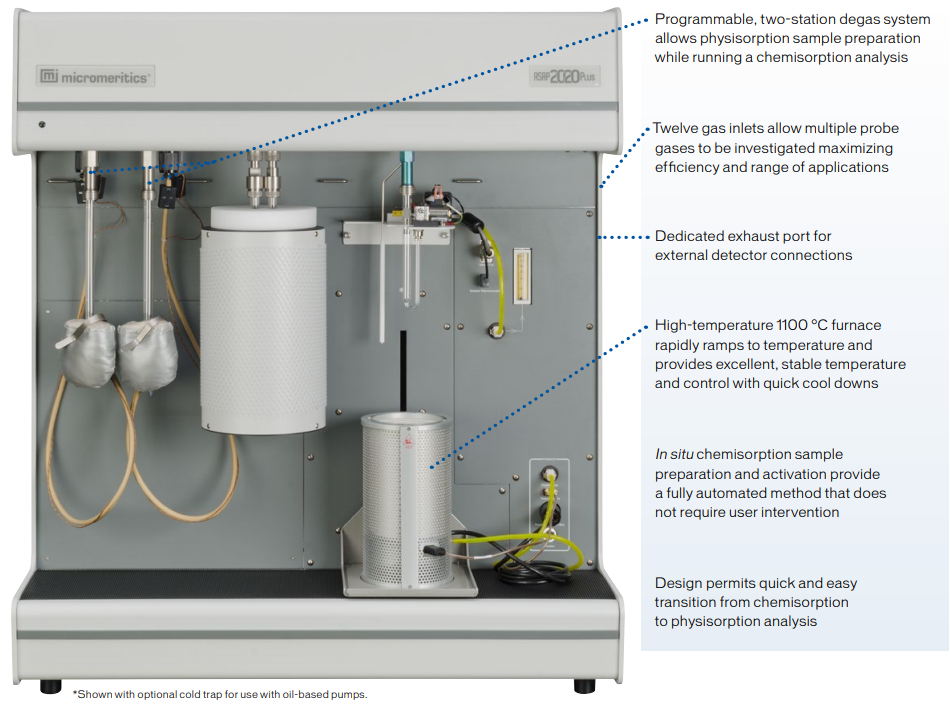

ASAP 2020 PLUS–Chemisorption

With the ASAP 2020 Plus Chemisorption option, users can discover your catalyst's physical and chemical characteristics, catalyst support, adsorbents, and other materials. Its one-of-a-kind design ensures a high level of system purity, allowing for low-pressure chemisorption isotherms.

Image Credit: Micromeritics Instrument Corporation

Designed for Expanding Needs

- Micropore Option: A 0.1-mm Hg transducer and a high vacuum pump are included. This device gives reliable porosity data on holes ranging in size from 0.35 to 3 nanometers and a wide range of micropore reports.

- Vapor Adsorption Option: Includes optional vapor attachments

- Cold Trap Option: For the particular application, there is a cold trap alternative available

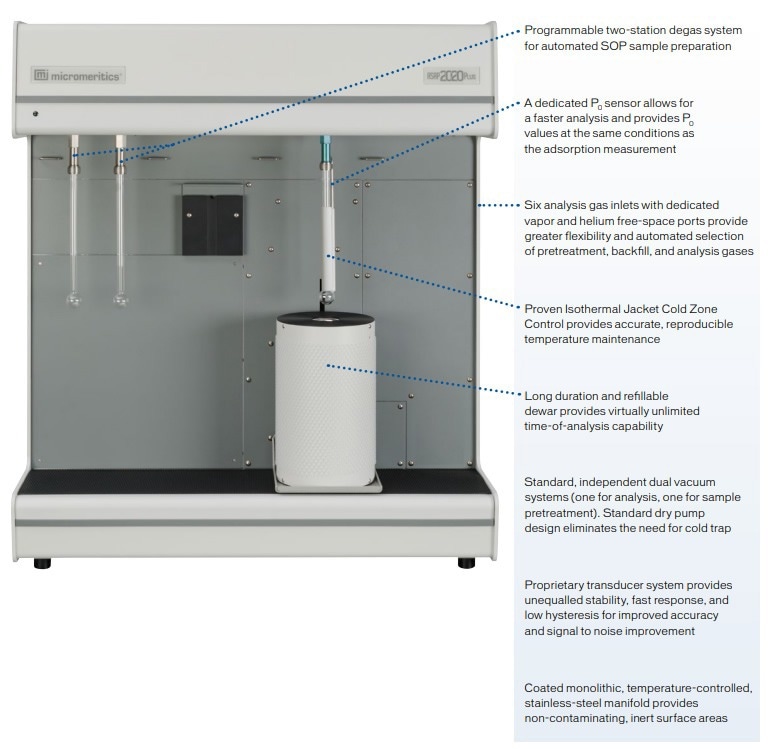

ASAP 2020 PLUS – Physisorption

The research-grade results in a customer-configurable instrument for a wide range of mesopore, micropore, and low surface area applications.

Image Credit: Micromeritics Instrument Corporation

Designed for Expanding Needs

- Micropore Option: A 0.1-mm Hg transducer and a high vacuum pump are included. This device gives reliable porosity data on holes ranging in size from 0.35 to 3 nanometers, as well as a wide range of micropore reports.

- Vapor Adsorption Option: Includes optional vapor accessories

- Cold Trap Option: A cold trap alternative is available for specific applications.

Application

Pharmaceuticals

The purification, processing, blending, tableting, and packaging of pharmaceutical goods and their usable shelf life, dissolving rate, and bioavailability are significantly influenced by surface area and porosity.

Ceramics

Surface area and porosity impact greenware curing and bonding, as well as final objects' strength, texture, appearance, and density. Shrinkage, crazing, and crawling are all affected by the surface area of glazes and glass frits.

Adsorbents

Understanding surface area, total pore volume, and size distribution is critical for industrial adsorbent quality management and separation process development. The surface area and porosity of an adsorbent influence its selectivity.

Activated Carbons

To achieve gasoline vapor recovery in vehicles, solvent recovery in painting processes, or pollution controls in wastewater management, surface area, and porosity must be tuned within tight limits.

Carbon Black

The surface area of carbon blacks utilized in tire production is correlated with wear life, traction, and performance.

Fuel Cells

To achieve the best power density, fuel cell electrodes must have a large surface area and carefully regulated porosity.

Catalysts

Production rates are influenced by the catalysts' pore structure and active surface area. By restricting the pore size, only molecules with the correct sizes may enter and depart, producing a selective catalyst that predominantly produces the intended product.

Paints and Coatings

A pigment or filler’s surface area affects its gloss, texture, color saturation, brightness, solids content, and film adhesive qualities. A print medium coating’s porosity in offset printing is crucial because it influences blistering, ink receptivity, and ink holdout.

Projectile Propellent

Propellant burn rate is a function of surface area; too high a rate can be harmful; too low a rate can cause malfunction and inaccuracy.

Medical Implants

Artificial bone can imitate actual bone that the body will accept, allowing the tissue to develop around it by controlling its porosity.

Electronics

Super-capacitor producers can reduce the amount of expensive raw materials they require while offering greater exposed surface area for charge storage by using high surface area materials with well-thought-out pore networks.

Cosmetics

Cosmetic producers frequently utilize the surface area as a proxy for particle size when the small powders’ tendency to clump together makes using a particle-sizing device for examination challenging.

Aerospace

The weight and functionality of heat shields and insulating materials are influenced by their surface area and porosity.

Geoscience

Porosity is related to the amount of fluid a structure can hold and the amount of work needed to extract it, making it significant in petroleum exploration and groundwater hydrology.

Nanotubes

The ability of a material to hold hydrogen is predicted using the surface area of nanotubes and microporosity.

More Applications

- Fibers

- Films

- Fertilizers

- Filters

- Glass

- Food Additives

- Adhesives

- Alloys

- Abrasives

- Carbonates

- Cement

- Clays

- Detergents

- Graphite

- Minerals

- Paper

- Polishing Compounds

- Polymers

- Resins

- Soils and Sediments

Accessories

Source: Micromeritics Instrument Corporation

| Part Number |

Description |

Comments |

| |

Gas Supply |

|

| 004-62230-32 |

Gas Pressure Regulator for CO2 |

2 stage gas regulator, CGA 320, delivery pressure range: 2-30 psig |

| 004-62230-35 |

Gas Pressure Regulator for CO and H2 |

2 stage gas regulator, CGA 350, delivery pressure range: 2-30 psig |

| 004-62230-54 |

Gas Pressure Regulator for O2 |

2 stage gas regulator, CGA 540, delivery pressure range: 2-30 psig |

| 004-62230-58 |

Gas Pressure Regulator He, N2, Kr, Ar |

2 stage gas regulator, CGA 580, delivery pressure range: 2-30 psig |

| 004-62230-326 |

Gas Pressure Regulator for N2O |

2 stage gas regulator, CGA 326, delivery pressure range: 2-30 psig |

| 004-62230-705 |

Gas Pressure Regulator for NH3 |

2 stage gas regulator, CGA 705, delivery pressure range: 2-30 psig |

| 004-25549-00 |

Reducer 1/8 in. Tube x 1/4 in. Tube |

|

| 004-25103-00 |

Ferrule, Front, Teflon, 1/4 in. |

For use with 1/8 in. tube × 1/4 in. tube reducer |

| 004-25104-00 |

Ferrule, Rear, Nylon, 1/4 in. |

For use with 1/8 in. tube × 1/4 in. tube reducer |

| 004-33601-00 |

Gas Regulator Expansion Kit |

Adds an additional outlet to the gas regulator |

| 004-33602-00 |

Gas Regulator Pressure Relief Kit |

Prevents excessive gas pressure in the event of a regulator failure (not to be used with toxic gases) |

| 290-25846-00 |

Gas Inlet Line 6' |

For connecting gas to the instrument, Copper, 1/8 in x 6 ft long |

| 290-25846-01 |

Gas Inlet Line 16' |

For connecting gas to the instrument, Copper, 1/8 in x 16 ft long |

| 201-25818-00 |

Gas Inlet Line 6', SS |

For connecting gas to the instrument, Stainless Steel, 1/8 in x 6 ft long |

| 201-25818-01 |

Gas Inlet Line 16', SS |

For connecting gas to the instrument, Stainless Steel, 1/8 in x 16 ft long |

| 004-25913-00 |

1/8 Peek Ferrule Set |

For sealing gas inlet lines into the gas inlet manifold assemblies |

| |

Vacuum Supply |

|

| 062-00200-00 |

Dry Vacuum Forepump |

For systems with high-vacuum option, 115/230 VAC |

| 004-62023-01 |

Service Kit Vacuum Forepump |

|

| 062-62801-23 |

Vacuum Oil Pump, 220/240 V |

Replacement pump only, does not include exhaust filter, foreline trap, or vacuum pump tray |

| 062-62801-11 |

Vacuum Oil Pump, 110/120 V |

Replacement pump only, does not include exhaust filter, foreline trap, or vacuum pump tray |

| 062-33002-00 |

Vacuum Foreline Oil Trap |

For one vacuum pump, includes: activated alumina, clamps, o-rings, fittings, and housing |

| 004-25509-00 |

Clamp |

NW 10/16, clamp to connect flex tube to pump or instrument |

| 004-25630-00 |

Centering Ring |

NW 16, sealing ring to connect forepump to instrument |

| 004-25652-00 |

O-Ring for Oil Vapor Trap |

Size 217, Viton |

| 004-16830-00 |

Activated Alumina |

500 g, for oil vapor trap |

| 004-16003-01 |

Vacuum Pump Oil |

1 ltr |

| 004-32177-00 |

Funnel for Filling Vacuum Pump with Oil |

|

| 004-27040-00 |

Vacuum Pump Exhaust Filter |

|

| |

Reference Materials |

|

| 004-16843-00 |

Reference Material 13X Zeolite |

Micropore reference material |

| 004-16844-00 |

Reference Material Y Zeolite |

Micropore reference material |

| 004-16821-00 |

Reference Material Silica Alumina |

Reference material for surface area and pore volume, S(BET) appr. 200 m2/g |

| 004-16833-00 |

Reference Material Carbon Black |

Reference material for surface area, S(BET) appr. 30 m2/g |

| 004-16858-00 |

Reference Material Alumina |

Reference material for surface area, S(BET) appr. 5 m2/g |

| 004-16816-00 |

Reference Material Alumina |

Reference material for surface area with Krypton analysis, S(BET) appr. 0.25 m2/g |

| |

General Operating Supplies |

|

| 003-63801-01 |

Cable Ethernet Straight-Thru |

For connecting the instrument to a computer |

| 202-25849-00 |

Dewar for Cold Trap |

3 ltr |

| 202-25850-00 |

Dewar for Analysis Port |

3 ltr |

| 202-31707-00 |

Cover Analysis Dewar |

|

| 202-31708-00 |

Cover for Cold Trap Dewar |

|

| 206-14701-00 |

Dewar Shield |

For use on sample port, cold trap, and degas ports |

| 202-14702-00 |

Dewar shield |

For use with Chiller Dewar Option |

| 202-33053-00 |

Stainless Steel Dewar Kit |

4 ltr, wide mouth, includes analysis dewar, cold trap dewar, and elevator adapter. Typically provides greater than 40 hours of unattended analysis. |

| 240-25901-00 |

Dewar Dip Stick |

For checking liquid nitrogen level in Dewar |

| 200-25840-00 |

Saturation Pressure (P0) Tube |

Includes isothermal jacket |

| 004-25006-00 |

O-Ring for P0 Tube |

Size 006, Buna-N |

| 003-26043-00 |

Heating Mantle |

With type K thermocouple, up to 450 °C, 24 V |

| 003-26045-00 |

Heating Mantle |

Side-laced to accommodate monolithic & nonstand sample tubes, with type K thermocouple, up to 450 °C, 24 V |

| 230-25808-00 |

Heating mantle clip |

For monolithic & nonstandard sample tubes |

| 004-61063-00 |

Tube for Cold Trap |

1/2 in. OD stem |

| 004-25469-00 |

O-ring for Cold Trap |

Size 014, Buna-N |

| 200-25979-00 |

Nut for Cold Trap |

|

| |

Sample Tubes and Accessories |

|

| 202-33100-06 |

Physisorption Operating Supplies |

Includes: 3 sample tubes (1/2 in.), O-rings, sample port frits, 1/8 Peek ferrule sets |

| 202-33100-12 |

Extended Physisorption Operating Supplies |

Includes: 6 sample tubes (1/2 in.), 1 filler rod, 1 isothermal jacket, 3 sample tube stoppers, O-rings, sample port frits, 1/8 Peek ferrule sets, sample tube brush, dewar cover, reference material |

| 240-61003-00 |

Sample Tube, 1/2 in. |

|

| 240-61002-00 |

Sample Tube, 3/8 in. |

|

| 240-61001-00 |

Sample Tube, 1/4 in. |

|

| 202-25903-00 |

Isothermal Jacket for 1/2 in. Sample Tube |

|

| 202-25902-00 |

Isothermal Jacket for 3/8 in. Sample Tube |

|

| 202-25901-00 |

Isothermal Jacket for 1/4 in. Sample Tube |

|

| 240-61016-00 |

Fillder Rod for 1/2 in. Sample Tube |

|

| 240-61015-00 |

Filler Rod for 3/8 in. Sample Tube |

|

| 240-61014-00 |

Filler Rod for 1/4 in. Sample Tube |

|

| 240-32000-00 |

Stopper for 1/2 in. Sample Tube |

|

| 004-32004-00 |

Stopper for 3/8 in. Sample Ttube |

|

| 004-32604-00 |

Cap (stopper) for 1/4 in. Sample Tube |

|

| 260-25843-00 |

Ferrule for 1/2 in. Sample Tube |

|

| 240-25802-00 |

Ferrule for 3/8 in. Sample Tube |

|

| 240-25803-00 |

Ferrule for 1/4 in. Sample Tube |

|

| 004-25044-00 |

O-Ring for 1/2 in. Sample Tube |

Size 013, Buna-N |

| 004-25022-00 |

O-Ring for 3/8 in. Sample Tube |

Size 012, Buna-N, |

| 004-25466-00 |

O-Ring for 1/4 in. Sample Tube |

Size 010, Buna-N, |

| 260-25890-00 |

Seal Frit for 1/2 in. Sample Tube |

With built-in check valve for air-sensitive samples |

| 260-25891-00 |

Opener for Seal Frit |

Installed in ports to open Seal Frits |

| 004-54130-00 |

Removal Tool for Seal Frit opener |

Tool to install and remove Seal Frit opener |

| 004-54618-00 |

Tool for Removing the Sample Port O-Ring |

|

| 004-27041-00 |

Sample Port Frit |

20 µm, SS, 1/4 in. |

| 004-25466-00 |

O-Ring for Sealing Frit in Sample Port |

Size 010, Buna-N |

| 240-14855-00 |

Sample Tube Holder |

Rack for 12 sample tubes |

| 240-32805-00 |

Support for Sample Tube Weighing |

Sample tube holder for balance |

| 240-25853-00 |

Funnel |

For sample tubes (fits various sample tube sizes) |

| 004-54609-00 |

Brush |

For cleaning sample tube, 330 mm long |

| 300-25824-00 |

Nut for Sample Tube |

|

| 202-33052-00 |

22 mm ID Sample Tube Kit |

Includes 5 sample tubes and accessories, see kit contents below |

| 202-61022-00 |

Sample Tube, 22 mm ID, 25 mm OD |

|

| 202-25904-00 |

Isothermal Jacket for 25 mm Sample Tube |

|

| 202-61022-01 |

Filler Rod for 25 mm Sample Tube |

|

| 004-32230-00 |

Stopper for 25 mm Sample Tube |

|

| 202-25870-00 |

Ferrule for 25 mm Sample Tube |

|

| 004-25609-02 |

O-Ring |

Size 022, Buna-N |

| 202-25868-00 |

Sample Port Fitting for 25 mm Sample Tube |

|

| 202-25869-00 |

Nut for 25 mm Sample Tube |

|

| 202-25871-00 |

Degas Port Fitting for 25 mm Sample Tube |

|

| 202-31709-00 |

Dewar Cover for 25 mm Sample Tube |

|

| |

Vapor Option Supplies |

|

| 003-20656-02 |

Cable, M/M 15 Pin D 5 ft straight-thru |

For connecting the controller to the vapor source |

| 003-20656-03 |

Cable, M/M 25 Pin D 5 ft straight-thru |

For connecting the controller to the manifold |

| 004-25103-00 |

Ferrule, Front, Teflon, 1/4 in. |

For sealing the vapor stem assembly to the vapor connector |

| 004-25104-00 |

Ferrule, Rear, Nylon, 1/4 in. |

For sealing the vapor stem assembly to the vapor connector |

| 004-25031-00 |

O-Ring for Replacement on the Vapor Stem Assembly |

Size 110, Kalrez |

| 004-25465-00 |

O-Ring for Replacement on the Vapor Stem Assembly |

Size 010, Kalrez |

| 004-61004-00 |

Dewar Flask |

350 mL |

| 004-61630-00 |

Glass Vapor Tube |

|

| 202-25878-00 |

Sample Port Insulator |

|

| 202-33054-02 |

Sample Tube Conductor Kit |

Contains 2 sample tube conductors and 2 O-Rings |

| 202-34150-02 |

Vapor Stem Assembly |

|

| |

Software and Manual |

|

| 202-20828-00 |

ASAP 2020 Plus Physisorption software program |

|

| 202-33027-00 |

MicroActive Software Package, interactive data analysis software |

| 202-42800-00 |

ASAP 2020 Plus Operator Manual (includes binder and dividers) |

| |

Temperature Control Devices |

|

| 205-33005-00 |

ISO Controller |

Micromeritics’ ISO Controller utilizes thermoelectric cooling based on the Peltier principle. The unit is designed to maintain a constant temperature between 0 °C and 80 °C when using CO2, N2, and other gases for adsorption analysis. The device rapidly cools and efficiently maintains temperature with minimal electrical current required. The sample area will accommodate up to 3 sample tubes. Heat removal is uniform and accurate when the unit is used with an appropriate liquid (ambient water or liquid antifreeze). The dewar section is placed on the instrument dewar elevator and then raised into position for analysis. |

| 025-00202-00 |

Chiller Dewar |

A closed plumbing system that circulates fluid from a temperature-controlled bath into a small Dewar filled with antifreeze in which the sample tubes are immersed. |

| 025-26004-00 |

Recirculating Bath |

Temperature range from -28 °C to 200 °C, 115 V, 60 Hz. Refrigerated and heating circulator for temperature control of the Chiller Dewar. Note: Recommended for use with the Chiller Dewar Option 025-00202-00 |

| 025-33001-00 |

RTD Probe for Recirculating Bath Temperature Control |

Optional RTD mounted in the bath and connected to the controller on the recirculating bath for more accurate temperature control (for use with 025/26004/00). |

| 021-00000-00 |

LN2 transfer system |

For easy filling of sample Dewars; includes 47 L Dewar, mobile platform, and pump with 100 cm discharge line |

Software

Software and Reporting Versatility

The user-friendly ASAP 2020 software uses a Windows® interface with tools and wizards to assist with organizing, starting, and managing the investigation. Raw data can be collected, arranged, reduced, archived, and stored with standardized sample data and analytical settings for convenient access in the future.

Data transfer routes, paper, or screens can send completed reports. Features include configurable reports, editable and scalable graphs, and cut-and-paste images. Additional capabilities consist of:

- Degas temperature profiles and treatment duration data are saved with the sample file for future reference and SOP compliance verification

- The Instrument Schematic screen shows the current operational condition of the instrument, including the real-time isotherm, and allows the operator to take manual control of the instrument if required.

- Overlays can be used to compare.

- Exportable data tables allow users to combine and compare data from several sources in a single Excel file.

- Three types of gas dosing procedures give excellent options for ensuring maximum speed with full accuracy for samples with widely varying isotherm shapes.

- The proprietary Smart Dosing™ procedure detects the sample’s ability to absorb gas and modifies the adsorptive dosages accordingly. This helps to avoid overdosing the sample and distorting porosity data.

- The user can enter any reference isotherm into the system via a data file or table. This isotherm can be used instead of the pre-programmed thickness curves when computing thickness for t-Plots, s (Alpha-S) plots, and BJH pore size distribution. For comparison, the reference isotherm can be superimposed with other displayed data.

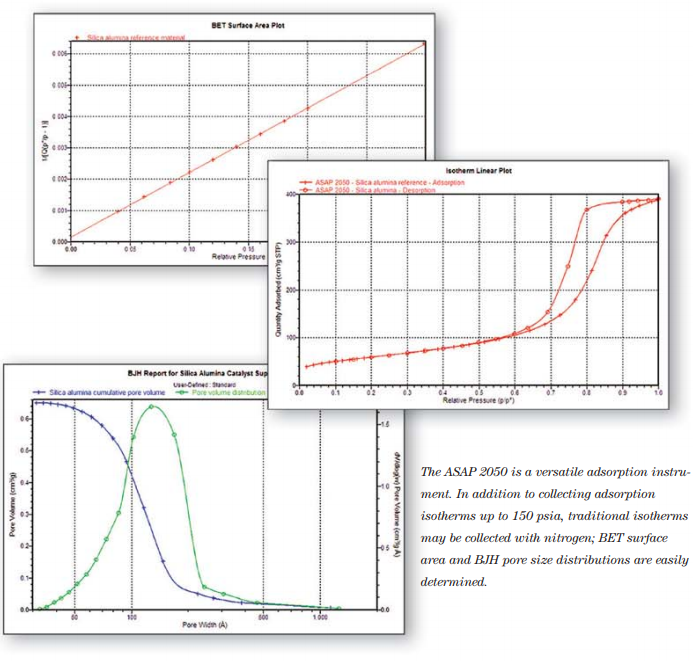

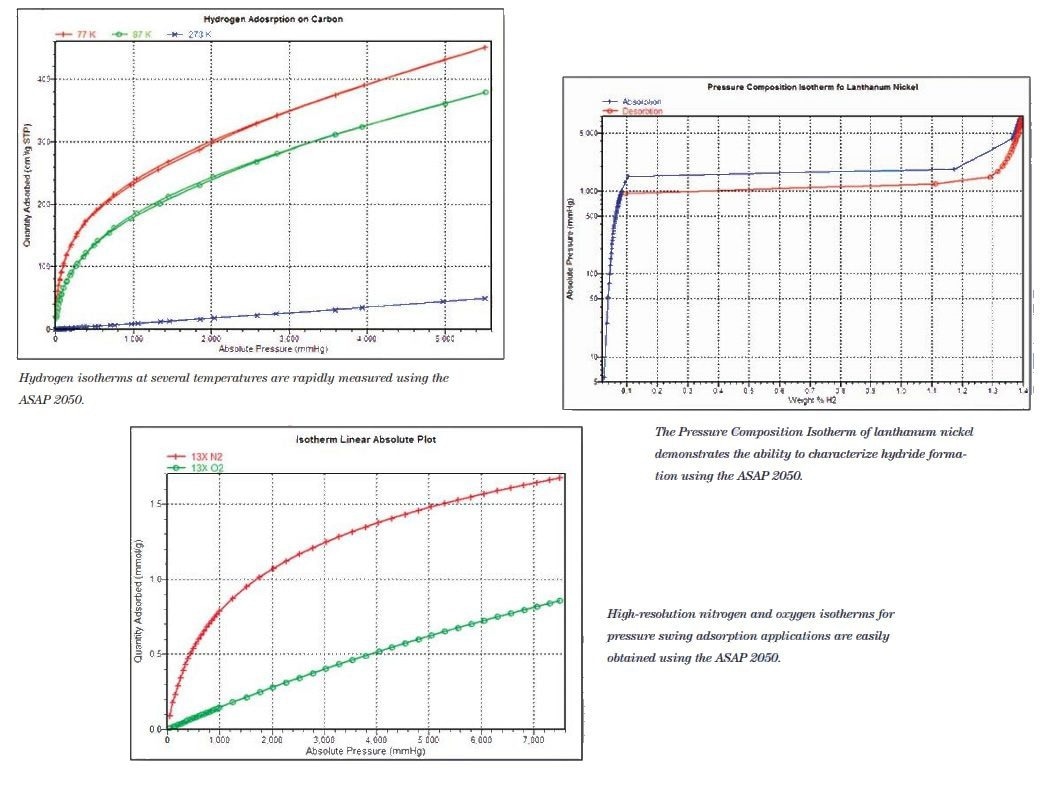

Analyses and Reports

The ASAP 2020 has strong data reduction software that generates several simple-to-read report alternatives. This provides a great deal of freedom in selecting the analytical constants that are most suited to your unique application.

All ASAP models can collect data across a specified pressure range segment or perform adsorption and desorption assessments throughout the whole pressure range, giving substantial surface area and porosity information.

Image Credit: Micromeritics Instrument Corporation

The model ASAP 2020 comprises:

- Single- and Multipoint BET (Brunauer, Emmett, and Teller) surface area

- Langmuir surface area

- Temkin and Freundlich isotherm analyses

- Pore volume and total pore volume in a user-defined pore size range

- F-Ratio plots that illustrate the difference between theoretical and experimental isotherm data

- Heat of Adsorption

- Repetitive Isotherm Cycling

- DFT (Density Functional Theory)

- Pore volume and pore area distributions in the mesopore and macropore range by the BJH (Barrett, Joyner, and Halenda) method using a variety of thickness equations, including user-defined, standard isotherm

Image Credit: Micromeritics Instrument Corporation