GeoPyc 1365 measures the envelope volume and density of formed pieces.

- Highly precise and reproducible outcomes

- Swift performance in a compact bench-top device

- Non-destructive analysis safeguards sample integrity

- Automated data collection and reporting

- User-friendly intelligent touch panel for seamless operation and reporting

- Optional Trans-Axial Pressure (T.A.P.) analysis to determine the compressed bulk density of powders, following ASTM Test Method D8097

- Applicable to formed items like roller compactor ribbons and sintered solids

- Yields pore volume and porosity data when combined with skeletal density

Description

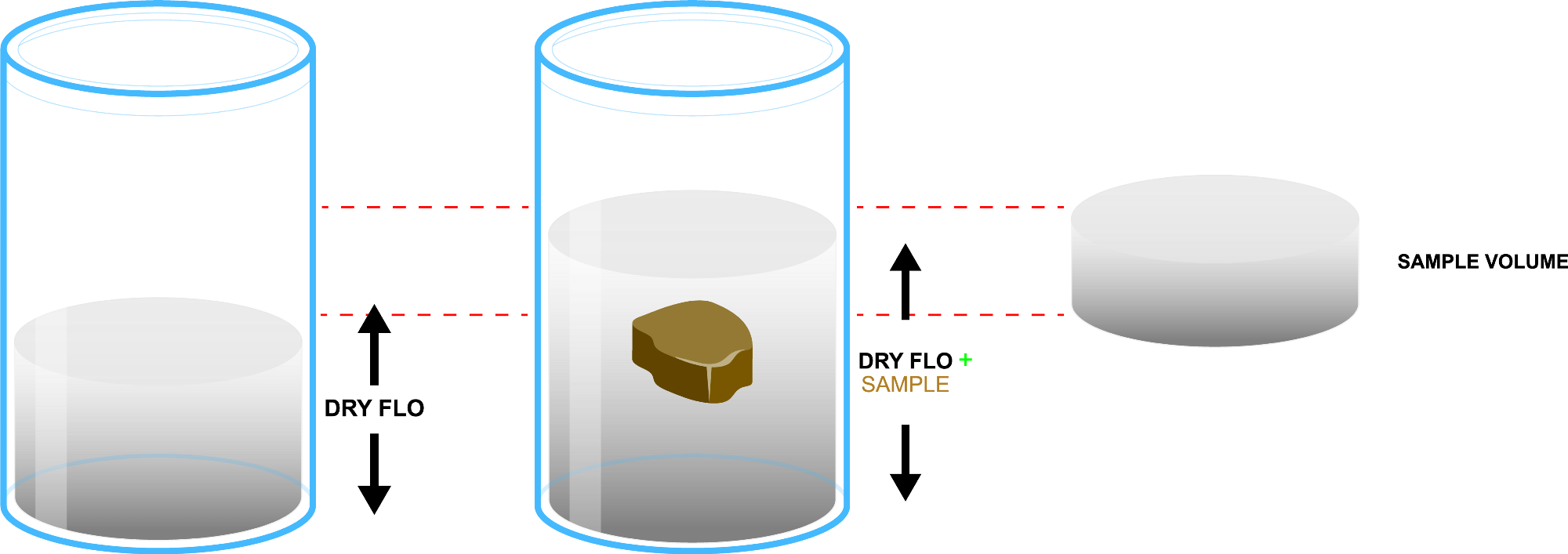

The GeoPyc system automatically calculates the volume and density of a solid object without the use of hazardous materials by displacing DryFlo, a dry, free-flowing powder with 'fluid-like' flow behavior. This medium comprises a narrow distribution of small, rigid spheres with high flow ability, forming a tight packing around the object under examination. The particles are small enough to closely conform to the object's surface during consolidation, without infiltrating the pore space.

Features and Benefits

- Provides swift, controlled-compression analysis with results available in as little as 15 minutes

- Applicable to both formed pieces for envelope density and powders for compressed bulk density determination

- Simplified operation through fully automated instrument control

- Facilitates easy cleaning and disposal of analyzed materials as it is free of hazardous materials and waste

- Can be utilized alone or provide results via email or web browser access

- Easy maintenance with a user-replaceable piston tip

- Allows programming, storage, and reuse of a large number of analysis method files

- Data is accessible as printed reports or in downloadable CSV format

- Has very low operating costs as hazardous materials are not required

Specification

Source: Micromeritics Instrument Corporation

| Reproducibility |

| When sample volume is at least 25 % of sample holder volume: Typically ± 1.1 % |

| Pressure Measurement |

| 12.7-mm (0.50 in.) ID |

Sample volumes between 0.3 cm³ and 0.8 cm³ |

| 19.1-mm (0.75 in.) ID |

Sample volumes between 0.8 cm³ and 2.4 cm³ |

| 25.4-mm (1.00 in.) ID |

Sample volumes between 2.4 cm³ and 5.3 cm³ |

| 38.1-mm (1.50 in.) ID |

Sample volumes between 5.3 cm³ and 13 cm³ |

| 50.8-mm (2.00 in.) ID |

Sample volumes between 13 cm³ and 25 cm³ |

| Physical |

| Height |

11 in |

| Width |

22 in |

| Depth |

15 in |

| Weight |

42 lbs |

| Electrical |

| Voltage |

85 to 265 VAC |

| Frequency |

47 to 63 Hz |

| Electrical Power |

95 VA |

| Environment |

| Temperature |

15 °C to 35 °C |

| Humidity |

20 % to 80 % non-condensing |

Technology

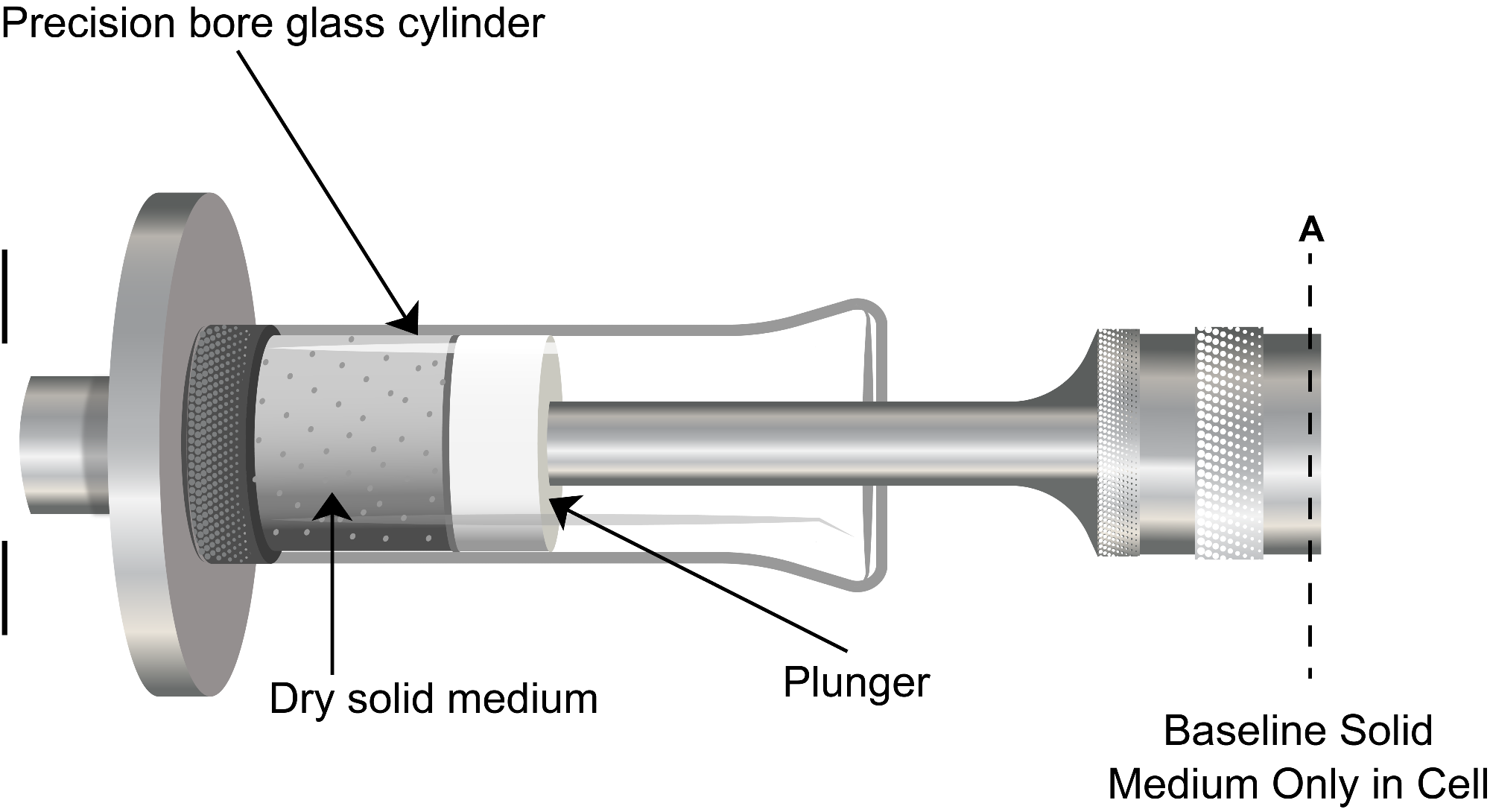

Repeatability and reproducibility are ensured through a controlled compaction method. The sample cell, housing the dry medium, is a precision cylinder. A plunger compresses the powder while the cell vibrates; the compression force is selectable and, thus, repeatable from test to test. Preliminary compaction with only the displacement medium in the cell establishes a zero-volume baseline.

The sample is subsequently introduced into the cylinder with the dry medium, and the compaction process is reiterated. The displacement volume of the medium is determined by calculating the difference in the distance (ht) the piston penetrates the cylinder during the test and the distance (h0) it penetrates during the baseline procedure (h=h0– ht) using the formula for the volume of a cylinder, V = πr²h.

The GeoPyc is controlled through an intelligent touchscreen. The entire process of data acquisition and reporting is automated, facilitating seamless integration into LIMS or other data-concentrating systems.

A range of sample chambers is available to accommodate various sample sizes. Post-analysis, a light shaking or dusting eliminates the Dry Flo, allowing for the reuse or retesting of samples.

The GeoPyc offers multiple operating modes, including full blank, computed blank, and reference solid calibration with variance, enabling customization of speed and accuracy according to individual requirements. Progress indications and preliminary results during analysis provide insights into the ongoing process.

Configuration

T.A.P. Density Option

The GeoPyc T.A.P. density option delivers accurate results comparable to traditional tap density analyzers but achieves this with increased speed, reduced noise, and heightened reproducibility.

When outfitted with the T.A.P. Density option, the GeoPyc assesses packing volume and calculates the bulk density of granular and powdered samples, such as pharmaceuticals and electrochemical substances, across a broad spectrum of compaction conditions.

To determine T.A.P. density, the sample chamber undergoes rotation and agitation while a precise, specified force is applied to the sample. A force transducer measures the consolidation force in Newtons, and the travel distance of the consolidation piston and plunger is measured in steps.

The user defines the applied force and the number of consolidations per analysis. The GeoPyc averages the measurements from each consolidation, automatically computing volume and density, and presents the results in cm³ and g/cm³.

Accessories

Source: Micromeritics Instrument Corporation

| Part Number |

Description |

Notes |

| |

Reference Materials |

|

| 136-33001-00 |

Chamber and Plunger Kit |

Includes one each of 12.7 mm, 19.1 mm, 25.4 mm, 38.1 mm, and 50.8 mm diameter chamber and plunger assemblies |

| 136-25801-00 |

12.7 mm Chamber and Plunger Assembly |

Includes both the 12.7 mm diameter chamber and corresponding plunger assembly |

| 136-25802-00 |

19.1 mm Chamber and Plunger Assembly |

Includes both the 19.1 mm diameter chamber and corresponding plunger assembly |

| 136-25803-00 |

25.4 mm Chamber and Plunger Assembly |

Includes both the 25.4 mm diameter chamber and corresponding plunger assembly |

| 136-25804-00 |

38.1 mm Chamber and Plunger Assembly |

Includes both the 38.1 mm diameter chamber and corresponding plunger assembly |

| 136-25805-00 |

50.8 mm Chamber and Plunger Assembly |

Includes both the 50.8 mm diameter chamber and corresponding plunger assembly |

| 136-25801-10 |

12.7 mm Chamber only |

Used with 12.7 mm diameter plunger assembly, 136-25801-11 |

| 136-25802-10 |

19.1 mm Chamber only |

Used with 19.1 mm diameter plunger assembly, 136-25802-11 |

| 136-25803-10 |

25.4 mm Chamber only |

Used with 25.4 mm diameter plunger assembly, 136-25803-11 |

| 136-25804-10 |

38.1 mm Chamber only |

Used with 38.1 mm diameter plunger assembly, 136-25804-11 |

| 136-25805-10 |

50.8 mm Chamber only |

Used with 50.8 mm diameter plunger assembly, 136-25805-11 |

| 136-25801-11 |

12.7 mm Plunger Assembly |

Used with 12.7 mm diameter chamber assembly, 136-25801-10 |

| 136-25802-11 |

19.1 mm Plunger Assembly |

Used with 19.1 mm diameter chamber assembly, 136-25802-10 |

| 136-25803-11 |

25.4 mm Plunger Assembly |

Used with 25.4 mm diameter chamber assembly, 136-25803-10 |

| 136-25804-11 |

38.1 mm Plunger Assembly |

Used with 38.1 mm diameter chamber assembly, 136-25804-10 |

| 136-25805-11 |

50.8 mm Plunger Assembly |

Used with 50.8 mm diameter chamber assembly, 136-25805-10 |

| 136-25801-07 |

12.7 mm Piston Assembly |

Used with piston rod 136-25801-03 to form 12.7 mm diameter plunger assembly |

| 136-25802-07 |

19.1 mm Piston Assembly |

Used with piston rod 136-25801-03 to form 19.1 mm diameter plunger assembly |

| 136-25803-07 |

25.4 mm Piston Assembly |

Used with piston rod 136-25801-03 to form 25.4 mm diameter plunger assembly |

| 136-25804-07 |

38.1 mm Piston Assembly |

Used with piston rod 136-25804-03 to form 38.1 mm diameter plunger assembly |

| 136-25805-07 |

50.8 mm Piston Assembly |

Used with piston rod 136-25804-03 to form 50.8 mm diameter plunger assembly |

| 136-25801-03 |

Longer Piston Rod |

Used with 12.7 mm, 19.1 mm, and 25.4 mm diameter piston assemblies to form corresponding plunger assemblies |

| 136-25804-03 |

Shorter Piston Rod |

Used with 38.1 mm and 50.8 mm diameter piston assemblies to form corresponding plunger assemblies |

| 004-25924-00 |

Quad Ring for 12.7 mm Piston |

Replacement quad ring for 12.7 mm diameter piston assembly |

| 004-25925-00 |

Quad Ring for 19.1 mm Piston |

Replacement quad ring for 19.1 mm diameter piston assembly |

| 004-25926-00 |

Quad Ring for 25.4 mm Piston |

Replacement quad ring for 25.4 mm diameter piston assembly |

| 004-25827-00 |

Quad Ring for 38.1 mm Piston |

Replacement quad ring for 38.1 mm diameter piston assembly |

| 136-25874-00 |

Quad Ring for 50.8 mm Piston |

Replacement quad ring for 50.8 mm diameter piston assembly |

| 136-25852-01 |

Piston Coupling Extender |

Used with 38.1 mm and 50.8 mm diameter pistons during analysis, and will all pistons during Zero Depth measurements |

| 004-16831-01 |

DryFlo, 3 L |

DryFlo media used for envelope density determinations |

| 004-32177-00 |

Funnel |

Aids when adding DryFlo to the chamber |

| 004-27059-00 |

500 µm #35 Sieve, 3 inch |

Use to separate DryFlo from the sample |

| 004-27065-00 |

Sieve Pan, 3 inch |

Use to catch DryFlo when using a sieve to separate DryFlo from the sample |

| 004-54613-00 |

Brush, 3/8 inch x 3.4 inch |

Use to brush DryFlo into and from chambers |

| 008-54105-00 |

Stylus |

For use with GeoPyc touchscreen |

| 003-63821-00 |

Balance Interface Cable |

Used to interface to optional direct-connect balance |

| 003-63801-01 |

Ethernet Cable |

Used to connect to network or computer for data archiving and reporting |

| 136-25815-00 |

Compartment Mat |

Covers the bottom of the analysis compartment |

| 136-42800-00 |

GeoPyc 1365 Operator's Manual |

Printed manual includes binder and chapter divider tabs |

| 136-33015-00 |

T.A.P. Density Option |

Allows determination of trans-axial pressurized density of powders |

| 011-00000-00 |

Analytical Balance, 120 g Capacity, Readable to 0.0001 g |

Optional direct-connect balance |

Software

Image Credit: Micromeritics Instrument Corporation

The GeoPyc features several operational modes accessible via the intelligent touchscreen interface. These modes encompass full blank, computed blank, and reference solid calibration with variance, enabling the fine-tuning of speed and accuracy tailored to the specific application.

Throughout the analysis, progress indicators and preliminary results provide real-time tracking of the ongoing process. User-specific information related to the sample can be inputted into the analysis reports. The available report options include Envelope Density, Volume Calibration, Blank Report, Force Calibration, and Instrument Log.

Micromeritics GeoPyc 1365 - Envelope Density Analyzer

Video Credit: Micromeritics Instrument Corporation

Image Credit: Micromeritics Instrument Corporation