The HPVA II Series of adsorption analyzers use the static volumetric technique to acquire high-pressure adsorption and desorption isotherms using gases such as methane, hydrogen, and carbon dioxide.

The volumetric method involves adding (dosing) a pre-determined amount of gas (adsorptive) into the chamber containing the sample to be tested. When the sample touches equilibrium with the adsorbate gas, the end equilibrium pressure is recorded. These data are later used to calculate the quantity of gas the sample has absorbed.

This process is repeated at specified pressure intervals until the highest preselected pressure is reached. Then the pressure can be reduced to provide a desorption isotherm. Each of the subsequent equilibrium points (volume adsorbed and equilibrium pressure) is plotted to give an isotherm.

Superior reproducibility and accuracy are realized by using individual transducers for monitoring low and high pressures.

Features

- Single port, or four sample ports with simultaneous analysis

- Large operating pressure range: High vacuum to 100 or 200 bar

- High and low pressure transducers for precise pressure measurements

- Manifold temperature controlled with heater for accuracy and stability

- Superior control of sample temperature by means of a cryogen dewar, recirculating temperature bath, or furnace

- Handles typical adsorbates such as oxygen, nitrogen, methane, argon, hydrogen, and carbon dioxide

- Excellent data reproducibility

- 100% automated analysis using interactive software

- Complete data analysis package using Micromeritics MicroActive Interactive Data Analysis Software

- Software includes NIST REFPROP

- Wide-ranging temperature capability: From cryogenic to 500 °C

HPVA II System Overview

Four Methods of Sample Temperature Control

- Refrigerated/heated recirculation vessel (user offers temperature control bath)

- Furnace permits experiments ranging up to 500 °C

- Four-liter, stainless-steel dewar for liquid cryogen

- Cryostat can precisely regulate sample temperatures from ambient conditions to 30 K

Manifold

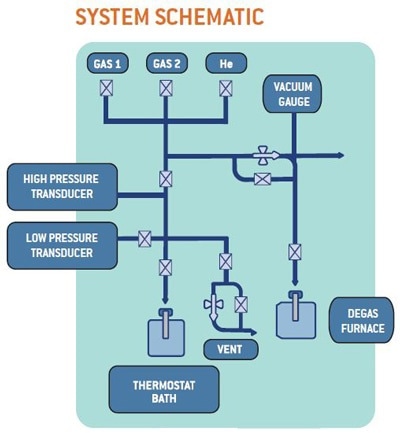

The entire set of valves in the manifold are pneumatically operated, high-pressure valves having Kel-F® seats. Valve tubing is built with heavy wall, 316L stainless steel and is connected via a VCR connection or welded. The insulated manifold region’s temperature is stabilized using a heater regulated by a modifiable PID controller.

Pressure Transducers

Two transducers are used for exact measurement of the system pressure. A 1000-torr transducer is used to accurately track pressures below 1 atmosphere and is safe from high pressure with an isolation valve and a cracking valve that relieves to vent. A high-pressure transducer (100 bar or 200 bar) is used to correctly monitor high pressures via the isotherm. As an option, the low-pressure transducer range can be chosen to better match the specific application. An optional 15 bar or 20 bar transducer can be organized.

Servo Valves

The servo valves are employed to accurately and automatically control the flow of the gas in the manifold to the vent or vacuum.

Vacuum Systems

They consist of a mechanical pump and internal Pirani vacuum gauge. The users can provide their own pump or buy the high-vacuum turbo pump package.

Typical Applications

Hydrogen Storage

Establishing the hydrogen storage capacity of porous carbons and metal-organic frameworks (MOFs) is key in the demand for clean energy. Stored adsorbed hydrogen in MOFs has a higher energy density by volume than gaseous hydrogen. The HPVA II offers a weight percentage plot that shows the amount of gas adsorbed at a set pressure as a function of the sample mass—the standard technique for appraising the hydrogen storage capacity of a sample.

Shale Gas

High-pressure methane can be dosed onto shale samples to produce adsorption and desorption isotherms. This offers the methane capacity of the shale at definite temperatures and pressures. The adsorption isotherm can be used to measure the Langmuir surface area and the shale volume.

Coal-Bed Methane

Porous coal samples from underground beds can be examined to establish their methane capacity at high pressures. This allows users to locate the methane adsorption and desorption properties which can be used in establishing approximate amounts of hydrocarbons present in coal-bed reserves. Kinetic data can also show the rate of methane adsorption and desorption at particular temperatures and pressures.

Carbon Dioxide Sequestration

High pressures realized with the HPVA II can mimic the underground conditions of areas where CO2 is to be injected. Configuring the HPVA II with a chiller/heater bath enables the users to assess the CO2 uptake at a variety of stable temperatures, delivering data that can be used to compute heats of adsorption.