Numerous food packaging companies are making use of Modified Atmosphere Packaging (MAP) or Equilibrium Modified Atmosphere Packaging (EMAP) to maintain the appearance and/or shelf life of their packed food. At Environics, the experts know it is vital that the MAP/EMAP gases must be accurate and consistent so as to guarantee the anticipated quality in the end products.

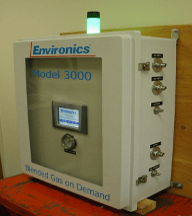

The Series 3000 Gas Mixing and Delivery system from Environics are designed for the precise mixing of MAP gases for case-ready meat packaging. Whether one is minimizing the oxygen levels with carbon dioxide, nitrogen, carbon monoxide, or various gases, the high accuracy and consistency of Environics’ mixers make them the units of choice for all of the requirements.

Flexibility: Environics’ systems automatically mix and dilute gases to produce precise gas mixes. The Environics® Series 3000 Gas Delivery/Blending system offers on-site gas mixing of 100% pure bulk gases and is configured to deliver a solution to using expensive premixed cylinders of gas.

Although two and three gas mixtures are most common, gas mixtures of more constituents can be produced. The main benefits of the system are cost savings in using pure gases versus premixed cylinders as well as the repeatability and accuracy of the mixture.

Whether a range of different gas blends or a single blend is used, the component concentration can be individually varied in reaction to the commands given. Customization of Environics’ case-ready meat packaging systems is possible.

Accuracy: Environics’ gas mixing technology is based on very precise control of thermal mass flow controllers (EFC202). Generally, thermal mass flow controllers provide an accuracy +/- 1% of full-scale flow. However, when integrated with Environics computerization and calibration, this accuracy specification is enhanced to +/- 1% of setpoint. The Full-scale error vs. Setpoint error document reveals the 10x improvement in accuracy of a thermal mass flow controller when employing Environics controlling technology.

Consistency: Environics systems have a repeatability of +/-0.05% of full scale. Both consistency and accuracy are based on the total flow rate.

Price Savings: By using pure gases instead of costly pre-mixed blends, a user’s system will help pay for itself.

Gas Conservation: The Series 3000 delivers a controllable positive pressure to meet the requirements of a process downstream. The mixer can be configured to supply gas to a ballast tank, turning off and on as the pressure rises and falls in the tank. This is beneficial for gas conservation when the demand for gas is intermittent or sporadic in use.

Optional Alarms: An optional audible and/or visual alarm can be fixed onto the top of the instrument to alert the operator of particular fault conditions. It is recommended that users use these alarms for all systems, and especially when using carbon monoxide. A condition that would trigger an alarm is if the interpreted concentration from the optional flow meters drops beyond a user-adjustable tolerance.

A new feature has been added. These alarms can also be emailed to keep users updated even when they are not onsite. This requires the IP address of the email server which must be a static IP address.

Custom Systems: Environics has several systems in the field and has developed a widespread library of applications and solutions to meet customers' requirements. Optional features including alarms, remote operation, or a gas humidifier are available.