Environics has introduced a new product—called Water Vapor Gas Standard Generator—that has been historically used for more than 25 years in the field.

The units have been designed to produce repeatable and precise moisture gas standards to users’ exact specifications.

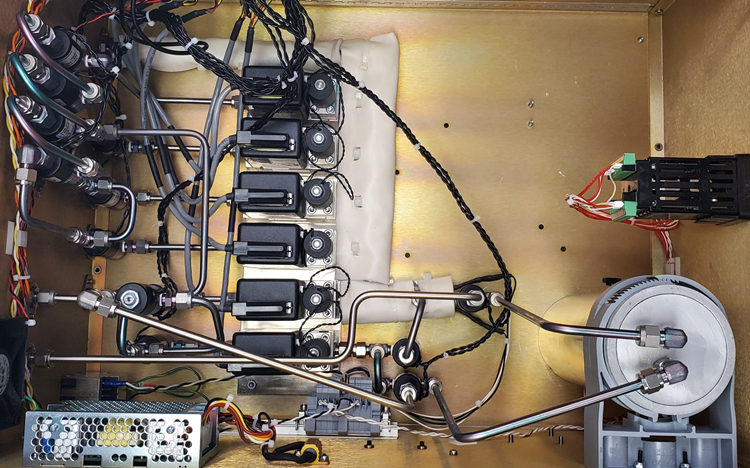

A passive system is the standard configuration. The units are customized based on the flows and concentrations required by users’ applications. If needed, the systems can accommodate multiple permeation ovens and multiple mass flow controllers to enable users to achieve their required complete range.

Individual MFC flow ranges from 10SCCM to 20LPM are standard, but higher flows are also available. To boost the function of the unit, the Water Vapor Gas Standard Generator can also be added to the Environics S4040 Gas Dilution or S4000 Gas Mixing System. Weight and footprint differ based on users’ needs.

Standard units include compression fittings and elastomer seals along the gas path. As an option, silicon lining of the gas path is also provided to reduce absorption. In the case of very low level moisture standards, Environics uses a two-fold method to improve unit construction.

Firstly, metal seals are employed to avoid the entry of ambient moisture that can affect the output whenever elastomer seals are used. Secondly, the electropolished gas path joints are orbitally welded to reduce absorption and prevent any leakage.

Besides this, all inputs and outputs are VCR fittings to additionally guarantee the integrity of users’ generated standards. Instead of, or apart from, these options, the chassis can be plumbed for constant purge with dry, inert gas (usually nitrogen). This option can be economical for those with an abundant source of nitrogen in their facility.

The systems are highly reliable, ensuring stability and precision of the permeation oven temperature within 0.1°C. This temperature can range from room temperature to 150°C.

Environics’ mass flow controller technology ensures that the dilution flow is accurate to +/ −1% of the setpoint, setting it above analogous equipment that is precise only to a full scale. Moreover, single level dilution implies that this precision is sustained for users’ entire range. As with all the systems, the units are NIST traceable.

Image Credit: Environics Inc.