The scanCONTROL series of laser scanners offered by Micro Epsilon are considered to be among the highest performing laser profile sensors all over the world based on their size, accuracy and measuring rate. It is possible to measure even the smallest of parts to the highest precision, which allows a new dimension of quality control.

The application areas are spread across all industries. Thus, besides determining the blade angle of razors, the laser scanner can also be employed for determining the thickness of potato slices, the completeness of laser welding seams, the quality of silicone adhesive beading, and the position of electronic components.

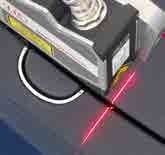

The Micro-Epsilon laser profile scanners can be used in production processes, automation, and quality control. Their operating principle is based on the laser triangulation method for 2D profile detection. They have the potential to detect, measure, and then evaluate the profiles on varied object surfaces. It is also possible to get 3D measurement values in the case of a moving objects or a traversing sensor.

Micro-Epsilon’s newest scanCONTROL 29xx-10/BL is a part of the laser profile scanner product series, and is treated to be a new commercial product. It allows high resolution measurements of extremely small objects.

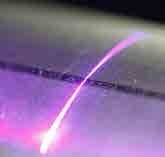

The scanner is built with a blue-violet laser diode and projects a 10 mm long laser line at a profile resolution of 1280 measuring points onto the measurement object. This indeed results in a point distance of only 7.8 µm, which permits the laser profile scanner to offer twice the resolution of preceding laser scanners along with a 25 mm measuring range.

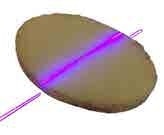

When compared to the red laser line, it is possible to project the blue laser line in a significantly more sharply manner. The blue laser light permits higher stability and does not penetrate the measurement object due to the shorter wavelength of the blue-violet laser. Thus, blue laser sensors provide more consistent measurements on red-hot glowing and organic objects.

The new laser profile scanner is employed in applications where the highest resolution and precision are needed, such as in mechanics, medicine, electronics, or in the production of precision components. In the production of tablets and smartphones, the scanner can examine, for example, the location of logos on the rear side, which have to be even with the housing.

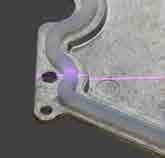

The scanCONTROL 29xx-10/BL is also made use of in the manufacture of USB connectors where it is essential for the gap size has to be precisely established in order to ensure that the connector fits effortlessly into the socket. The other vital factors include the relative position of the “tongue” in relation to the outer sides and the total width of the connector.

The scanCONTROL 29xx-10/BL scanners are mass produced and they are expected to attain inspection intervals of > 0.1 s which must be adhered to. Faulty parts are sorted out via a NOK signal, disposed, or repaired.

Applications

scanCONTROL/gapCONTROL - Sensor, solution and system from a single source

Micro-Epsilon has several years of experience in incorporating extremely efficient laser line sensors to user applications and in offering complete systems from a single source.

LLT sensors are adapted to a range of common applications in production processes, automation, and quality control.

Defect recognition on worktops

Filter height in the automotive industry

V-gap measurement on pipes

Gap measurement on a car body

Profile measurements on brake disks

Measuring weld seam profiles

Tyre inspection

Distance measurement at the centre console

Inspection of the adhesive beading

scanCONTROL/gapCONTROL BL

The laser scanners available with a blue laser line are employed for multi-dimensional measurement on red-hot glowing metals, and transparent and organic materials. The blue laser light permits greater stability and does not penetrate the measurement object since the blue-violet laser has a shorter wavelength.

When compared to red lasers, blue laser sensors allow more reliable measurements on red-hot glowing and organic objects. The blue laser line is greatly-focused and allows laser scanners with 10 mm line length to be employed in maximum precision.

Blade angle of razors

Production of steel-forged rings

Thickness measurement of potato slices

Position of electronic components

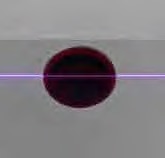

Gap measurement of inserted glass

Inspection of silicone adhesive beading

Measurement of hard/sliced cheese

Completeness of laser welding seams

Thermal tests

Compact laser triangulation sensors