Semilab has introduced a new in situ Spectroscopic Ellipsometer called inSE-1000. This tool offers quick access to optical properties and layer thicknesses via ellipsometric spectra analysis at the time of layer deposition or etch processes performed in vacuum chambers like ALD chamber. It can be also installed on load lock, cooling and transfer chamber for post process check without breaking the vacuum.

The inSE-1000 is part of Semilab’s ellipsometry tool range designed particularly for measurement on vacuum chambers during deposition or treatment processes performed in load locks.

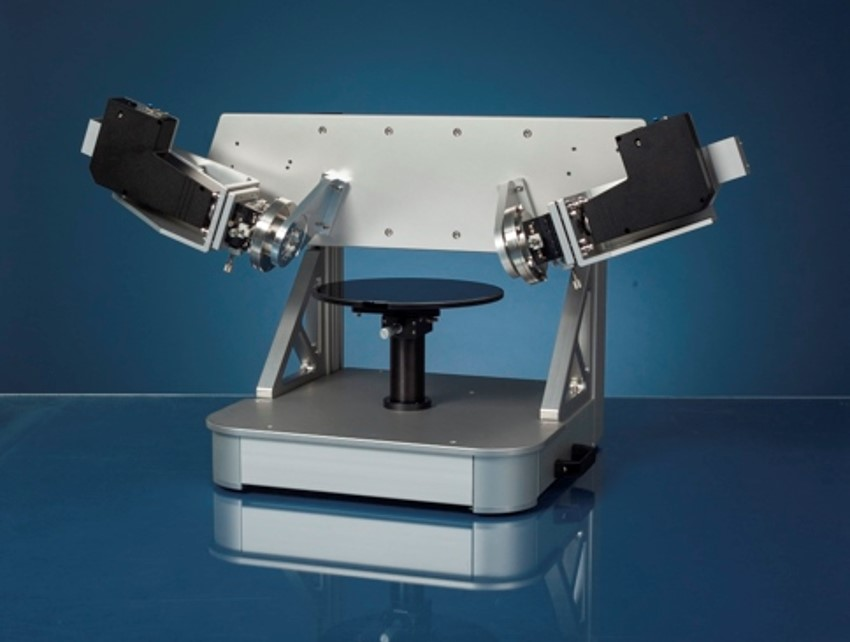

The arms of the ellipsometer can be also easily mounted and positioned on an offline test bench or on the vacuum chamber for an in-depth investigation of the end product. The supplementary systems and electronic components are located in a cabinet, which can be positioned next to the deposition tool. On-demand measurement sequences with the two-way communication protocol and the deposition tool are enabled by the Ethernet interface.

Features and System Specifications

- Optical fiber provides 75 W, short arc Xenon lamp

- CF-40 vacuum port interface

- Compact arms

- Beam divergence less than 0.2° (no focusing, in parallel beam)

- Rotating compensator optics

- Spectral resolution for quick mode

Software

- Modeling of each layer with all established methods such as anisotropic layer evaluation, phase node model, periodic layers, alloy model, dispersion laws, or user-specified free formula

- Direct visualization of the measurement data and the fitting results—optical and thickness properties

- The biggest (k, n) database

- Ethernet-based communication protocol with the deposition tool computer

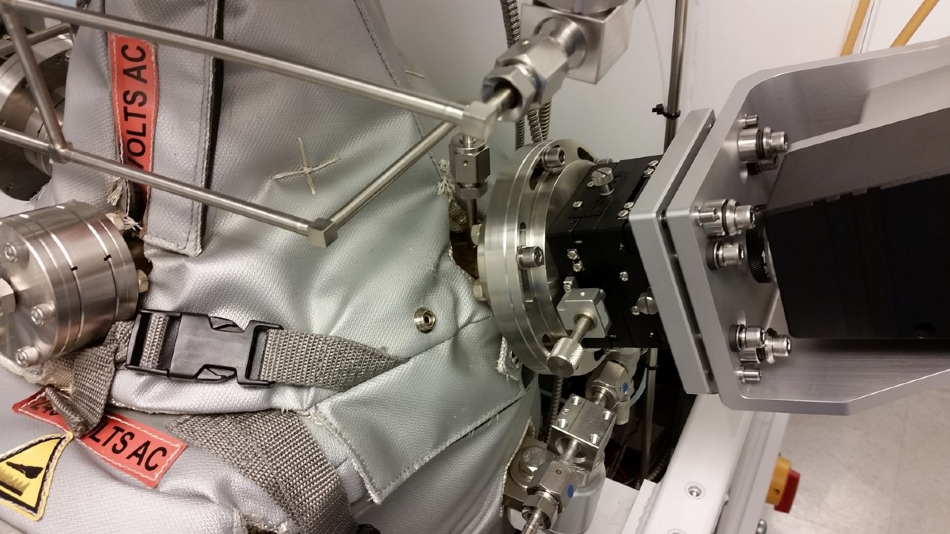

InSE 1000 on Picosun ALD

InSE 1000 on ALD

Ex situ bench