The ProberStation 200™ from Semilab allows automated AFM measurements while guaranteeing the lowest cost per measurement for failure analysis, quality assurance and quality control, along with the utmost ease of use.

The ProberStation 200™ has an open design that provides space to concurrently mount additional equipment, like a nano-indenter or optical microscope, to the AFM.

Performance

- Excellent stability and scan rates are ensured, thanks to the compact design of the DS 95 AFM scanner

- The completely digital C-32 SPM control electronics offer spearhead imaging control and feedback performance

Ease of Use

- The special option for plug-and-play cantilever exchange ensures safe and rapid operation of the system

- An incorporated optical axis in the AFM scanner allows complete visual control during approach and positioning

Automation

- The high precision XY stage enables coordinate-based navigation on specimens

- Script-based measurement recipe generation allows user-specified automated measurements and offers cost- and time-efficient measurement data collection

- Extra optical equipment can be fitted for pattern recognition or alternative microscopy modes

With the DS 95 SPM scanner range, Semilab offers the ultimate combination of performance and ease of use. The DS 95 SPM scanners reflect a decade-long experience in the domain of SPM application and manufacturing to help users realize the best and most consistent results in the shortest time possible.

The ProberStation 200™ is an advanced stage meant for AFM measurement on bulk samples. The long-range XY translators of the ProberStation 200™ help analyze 200-mm specimens at all places and up to 300 mm on certain sample regions.

The stage can be fitted with an optical reference system for greater positioning accuracy as needed for defect review applications. The entire positioning progress is highly stable and completely automatic, making it ideal to examine various structural features on an individual sample in overnight and long-term measurement runs.

In comparison with interferometer-based positioning systems, the investment effort is drastically decreased by offering similar performance.

The completely programmable sample positioning allows independent AFM measurements on various sample positions with automatic report generation and automatic image analysis. The integration with high end optics allows an automated preselection of sample sites for examination of AFM.

Hence, the roberStation200™ setup is the ultimate solution for process development and application, industry quality control and research and development environments. The unrestricted space for OEM or custom integration of extra analytical equipment paves the way for research applications.

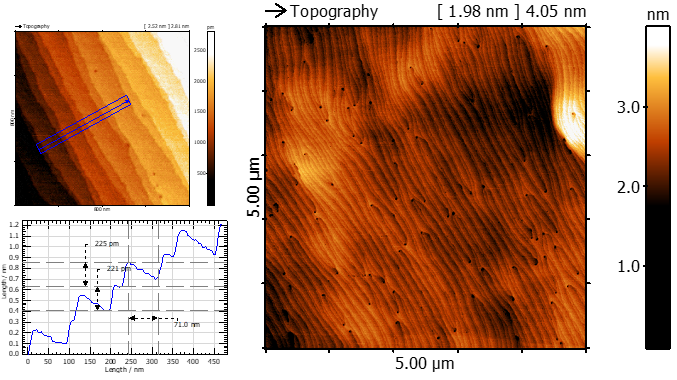

The topography image on the right side shows a GaN sample presenting atomic steps and defects. Graph and image on the left side show a section analysis enabling to determine the step height of the single atomic steps. Image Credit: Semilab Semiconductor Physics Laboratory