The SPT-20 is an easy to operate metal sputter coater offering the best value on the market for an automated coater. It is used as a pre-treatment product for non-conductive samples to improve imaging resolution, sample conductivity, electron charge reduction and reduce beam damage to sensitive samples.

The SPT-20 coater integrates an LCD touch-screen user interface for operation. The external vacuum pump (included) allows fast vacuum to be achieved as resulting in an adequate coated grain size for most standard SEM analysis.

Description

The SPT-20 ion coater is a device for coating conductive materials such as Pt-Pd, Pt, Au, and Pd onto the surfaces of samples through the DC sputtering principle. In addition, non-conductive samples are used for visualization under electron microscopes, as well as to safeguard the surfaces of samples from the injected electron beam and to assist the flow of electrons. They can even be used as a thin film-type electrode formation.

- Digital ion coater

- Vacuum coating — single-touch coating system up to the normal pressure

- Coating current feedback function ensures stable coating

- Makes use of low-noise rotary pump

- Can be utilized with several metal targets

Upon applying a voltage between the target and the sample in a set vacuum state within the chamber, the leftover air molecules turn into plasma (ionized), and electrons and ions are formed.

Furthermore, the ions and electrons that travel at a high speed collide with the gas molecules, where ionization is expedited by repelling electrons of the molecules. The ensuing ions collide on the cathode part of the target and strike the target particles, making the particles of the raw material collide and bond to form a coating layer.

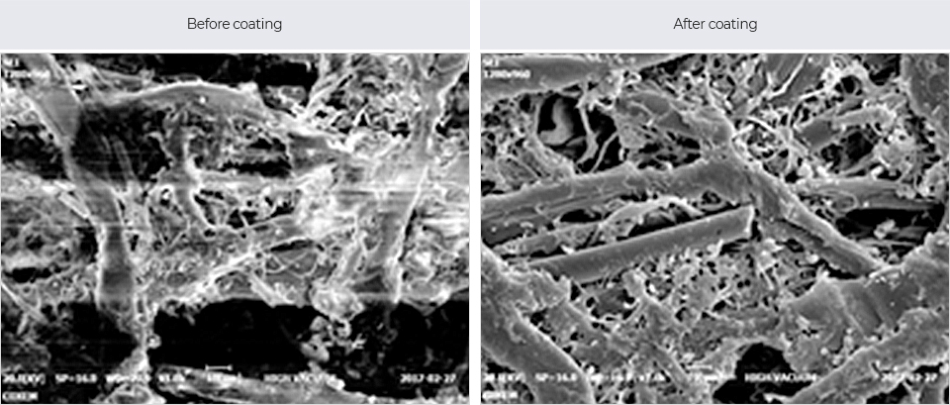

Application to SEM