Fluke Process Instruments’ Datapaq Oven Tracker Systems are specifically designed to provide thorough thermal profiles for paint curing, powder coating, component delivery and general paint, powder and e-coat OEM tools ranging up to 400 °C.

With such thermal profiling solutions, users can supervise the entire process from within the oven and obtain crucial data via fully automated reporting. This helps convert raw data into useful analytics that demonstrate if optimal temperatures are met to guarantee greater results.

Every Datapaq system includes strong InsightTM analysis software, enabling users to control data logger procedures and transform raw data into usable analytics to better understand, regulate and optimize the process.

Also, each software option allows users to print comprehensive, approved and legible profile reviews to ensure that products meet industry standards (such as ISO9000).

The Datapaq Oven Tracker Systems, with their robust thermal barrier options, can be particularly customized for a variety of OEM applications to help improve the quality of the product, eliminate waste and prove conformity.

The thermal barriers provide strong thermal security and consistent quality run after run, and many barrier designs feature patented silicone-free construction, removing paint finish deformities and pollutant issues.

Since each application has its own set of different requirements, designers have created a series of Datapaq Oven Tracker Systems to better fit users' specific applications.

Below is some more information about the entire Datapaq Oven Tracker System, including the powerful InsightTM software, data logger choices and thermal barriers.

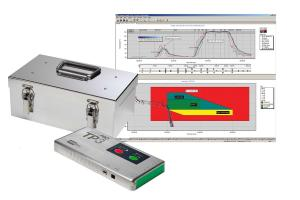

Datapaq® Oven Tracker® XL2 Temperature Profiling System

This premium oven thermal profiling system offers a comprehensive fix in automotive assembly, component supply and general paint/powder or E-coat OEM. With a choice of basic or specialized thermal barriers and powerful InsightTM analysis software, Oven Tracker® XL2 allows the user to control and optimize the healing process.

Image Credit: Fluke Process Instruments EMEA

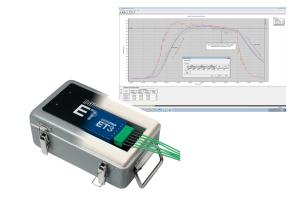

Datapaq® EasyTrack3 Thermal Profiling System

The EasyTrack®3 system is designed for the day-to-day necessities of powder coating applications. They are user-friendly, precise and dependable. It is suitable for every paint/powder coater and supplier because it is available in multiple system configurations with software, thermal barrier and thermocouple options.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Customized Industrial Oven Thermal Profiling Systems

When standard and specialty systems do not satisfy the exact application needs of the user, Datapaq will construct a custom system using its Insight™ Oven Tracker software, a wide range of custom barriers and the Datapaq DP5 or Datapaq TP3 temperature data loggers.

Datapaq provides a full thermal profiling system for real-time data analysis. The Radio Telemetry System is compatible with both Datapaq TP3 data loggers and Datapaq DP5.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Specialty Thermal Profiling Oven Systems

These system solutions have been developed to meet specialized process needs in a range of applications, including coil coating line ovens, rotomolding oven profiling, fabric processing in stenter, three pieces can wicket oven cure, aluminum bottle or tube monoblock and physical vapor deposition.

Image Credit: Fluke Process Instruments EMEA