Fluke Process Instruments has designed the Thermalert 4.0 Series Pyrometers for aggressive environments and to provide precise, real-time temperature measurements for process control applications in plastics, metals, glass, oil and gas, and food. This powerful solution comes in a small, integrated package that is simple to install and use, enabling the user to take process control to the next level.

Thermalert 4.0 Series Pyrometers features:

- Enhance process control with a wide selection of spectral ranges and focus distances tailored to the application

- Users can select from analog and digital communication protocols

- Save time on setup with plug-and-play technology and incorporated laser sighting

- Safeguard the process and employees with intrinsically safe ATEX/IECEx/CCC-IS certification

Image Credit: Fluke Process Instruments

Image Credit: Fluke Process Instruments

At a Glance

Fluke Process Instruments’ Thermalert 4.0 Series Pyrometers have several integrated infrared temperature sensors with their broadest spectral ranges that may be used for a wide range of process control applications.

Every pyrometer complies with Industry 4.0 standards, integrates ground-breaking digital technology with typical two-wire installations for all configurations, and is available with ATEX and IECEx certification.

This sophisticated infrared measurement sensor, with multiple communication options, delivers the tools users need to comprehend the temperature data and regulate their specific process in a compact, integrated package that is simple to install and operate.

Thermalert 4.0 Pyrometers

Thermalert 4.0 Series Pyrometers offers a comprehensive picture of even the toughest environments, with the potential to endure ambient temperatures up to 85 °C (185 °F) without additional cooling. They also offer multiple wavelength options to accommodate a wide range of applications.

Each pyrometer is built with a best-in-class optical resolution that changes depending on the application. It also provides multiple communication choices to satisfy the process needs, such as two-wire loops driven by RS485, digital outputs (Ethernet, EthernetIP, ProfinetIO), and analog outputs.

Laser sighting, ATEX/IECEx certification, and a wide range of accessories (including high-temperature enclosures) are available in all models.

Key Features

- Durable stainless steel IP65 / NEMA4 enclosures

- Temperature readings range from −40 °C to 2300 °C (−40 ºF to 4172 °F)

- Endures ambient temperatures from −20 °C to 85 °C (−4 °F to 185 °F)

- Galvanic isolated outputs

- Intrinsically safe models (ATEX/IECEx/CCC-IS certification)

- Embedded laser sighting

- Analog input for ambient compensation and modifying emissivity setting

- Plastic lens option available for food applications

- Multiple communication interfaces:

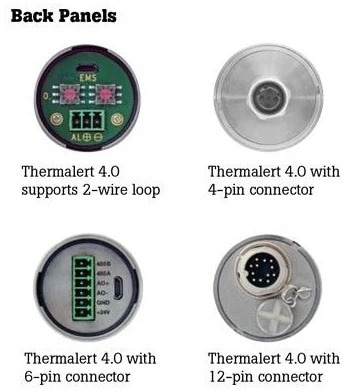

- 2-wire loop options for HART protocols

- 2-wire loop powered for analog communication

- 4-wire (Fieldbus Support—Ethernet, EthernetIP, ProfinetIO)

- 12-wire M16 and 6-pin terminal block for digital communication (RS485)

- Wide choice of focus distances

- Advanced signal processing

DataTemp® Multidrop Software

The DataTemp® Multidrop Software allows users to embed Thermalert 4.0 infrared sensors into their process control system. Each software solution provides the tools to “plug and play,” easily configuring the sensors and tracking temperatures with a graphical display in real-time.

The software's bar graph feature displays temperature profiles throughout the process. The program may also record and archive process temperatures and display high- and low-alarms, making it simple to determine when conditions exceed the set parameters.