Whether a user is working with raw materials or finished items, assessing atmosphere and product temperatures throughout the furnace is necessary to assure product quality and overall efficiency. The Datapaq Furnace Tracker System, which includes a Datapaq TP6 Data Logger, durable thermal barriers and user-friendly Insight® Software, provides real-time temperature data.

Infrared solutions, which are appropriate for fixed installations in plants and machines, seamlessly integrate into users’ process monitoring systems via industry-standard guidelines. Every furnace tracker thermal profiling system has been built to be used repeatedly in harsh environments while giving reliable and in-process temperature surveys.

Data Logger

Image Credit: Fluke Process Instruments EMEA

With the Datapaq TP6 and DP5 Data Loggers, users can safeguard the temperature data, every time. They are built to withstand the harshest operating conditions.

Thermal Barrier

Image Credit: Fluke Process Instruments EMEA

The thermal barriers are ideal for a variety of heat treatment processes since they provide the highest heat protection while staying durable and simple to use.

InsightTM Software

Image Credit: Fluke Process Instruments EMEA

Users can convert raw data into actionable analytics with software that features a simple user interface, context-sensitive help screens and support options for infrequent users.

Datapaq® Furnace Tracker Thermal Profiling System

Video Credit: Fluke Process Instruments EMEA

Datapaq DP6 Data Logger

Image Credit: Fluke Process Instruments EMEA

With the range of data loggers designed to withstand the most demanding operating conditions, users always get the temperature data they require. The Datapaq TP6 Data Logger has a 316-grade stainless-steel case, an IP67 rating and robust software choices that would provide real-time actionable analytics.

This enables users to improve the system by tracking product temperature from inside the furnace and adjusting oven settings to boost efficiency, utilization and to meet any heat treating demands.

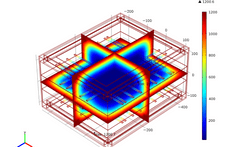

Thermal Barriers

Image Credit: Fluke Process Instruments EMEA

The thermal barriers are useful for high heat treating processes since they are crafted to provide maximum thermal protection — whether users are working with vacuum and controlled atmosphere, slab reheat or solution aging applications.

Choosing the correct barrier is a crucial aspect in enhancing the profiling capabilities, and if a suitable barrier is not available, Fluke offers bespoke development services to develop a solution that is tailored to users’ procedures.

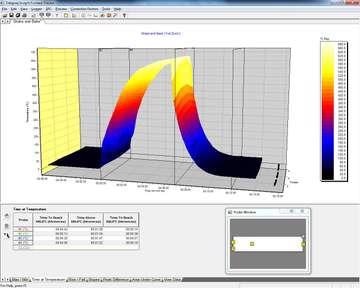

Insight™ Software

Image Credit: Fluke Process Instruments EMEA

Every Datapaq InsightTM Software product has been designed to transform raw data into actionable information. To assist novice users, all three software options have a simple user interface, context-sensitive help screens and wizards.

The basic software is a low-cost solution for general profile checks, whereas the advanced TUS software generates full temperature profiles and detectable reports for CQi-9 and AMS2750.

The power to change the language and email results directly from the software at the touch of a button allows users to share data across the processing facility and around the world, regardless of whether the user is on a computer or a mobile device.