Measuring both product temperature and its environment is an essential aspect to ensure both product quality and process effectiveness for metal heat treatment industries.

Fluke Process Instruments has crafted the most powerful and advanced furnace profiling systems. Fluke offers everything users need to classify their operation, no matter how difficult it is. It offers data loggers and thermal constraints to intuitive software reporting and analysis.

The Datapaq Furnace Tracker System is built to be used multiple times in the harshest industrial operations while still offering consistent and precise through-process temperature survey data. Each system will assist users in enhancing performance and system precision, reducing downtime and TUS reporting times, among other things.

The Datapaq TP6 has a 316-grade stainless-steel case and is obtainable with 10 or 20 thermocouple channels. Also, the data logger is completely waterproof (IP67-rated) and is equipped with Bluetooth technology to allow for fast and easy configuration from a PC or mobile device. Extra elements for particular products are highlighted below.

The selection of the best thermal barrier for high-temperature treatment processes is a key step towards enhancing users’ through-process profiling functionality.

Fluke Process Instruments cover a diverse range of thermal barriers that have been constructed to provide the highest heat protection — such as new sealed quench designs — in applications such as vacuum and controlled atmosphere, slab reheat and solution aging and many others.

Furnace Tracker Systems from Datapaq are crafted for authentic and precise in-process temperature survey data, as well as to fulfill the necessary process requirements in the most demanding industrial settings. The enigmas of the process can be disclosed. Users can find the profiling system in the list below.

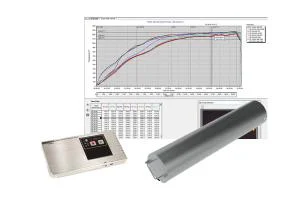

Datapaq® Furnace Tracker for Metals Heat Treating up to 1050 °C

This Datapaq Furnace Tracker System has been designed for processes ranging up to 1050 °C (1922 °F), including the TB40 or TB49 thermal barrier series, allowing users to obtain consistent and valid temperature profiles from the inside of the greatest conveyorized and batch furnaces.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Furnace Tracker Vacuum Heat Treatment

The Datapaq Vacuum Heat Treatment System has been engineered to survive pressures of up to 20 Bar (290 PSi) and features the TB45 or TB46 series thermal barrier, allowing users to perform TUS and thermal profiles for vacuum and carburizing applications up to 1200 °C (2192 °F).

Image Credit: Fluke Process Instruments EMEA

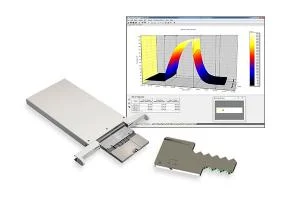

Datapaq® Furnace Tracker Sealed Quench System

The Datapaq Furnace Tracker Sealed Quench System has been specifically developed for the aluminum solution heat treatments and gives precise temperature profiles in real-time throughout all three process stages — solution treatment, aging and quench.

Image Credit: Fluke Process Instruments EMEA

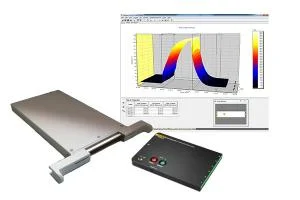

Datapaq® Furnace Tracker Temperature Uniformity Survey Systems

The product modeling and temperature uniformity surveying (TUS) functions are separated by this robust hardware and sophisticated software package, each having its own mystics and analysis. The TUS software executes comprehensive analysis calculations instantly, supports real-time alarms and can be used to print a survey report in accordance with the AMS2750 standard.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Furnace Tracker for Controlled Atmosphere and Vacuum Brazing

Datapaq Furnace Tracker System, intended for frequent use in CAB and vacuum implementations, allows users to monitor accurate temperature profiles in real-time to guarantee every design satisfies requirements.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Furnace Tracker for Slab and Billet Reheat Process

This Datapaq Furnace Tracker System, crafted for severe environments, gives precise in-process product core and surface temperature profiles from within slab and billet reheat furnaces in real time.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Furnace Tracker Rotational Thermal Profiling Systems

This Datapaq Furnace Tracker System, crafted for processes ranging up to 1000 °C (1832 °F), rolls with pipes and tubes during thermal treatment and quenching, allowing users to obtain accurate and precise in-process temperature profiles and surveys from conveyorized and walking beam furnaces.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Furnace Tracker Systems for Glass Tempering and Bending

This Datapaq Furnace Tracker System, specifically designed for glass tempering applications, gives precise temperature profiles in actual time for all sorts of glass, like hard- and soft-coated low-e glass.

Image Credit: Fluke Process Instruments EMEA

Datapaq® Furnace Tracker Specialty Profiling Systems

These systems, which are intended to provide the advantages of temperature profiling in niche or difficult heat treating operations, allow users to obtain consistent and valid temperature profiles from the inside of furnaces in processes where lengthy trailing thermocouples are not an option.

Image Credit: Fluke Process Instruments EMEA