The LFA 717 HyperFlash® HT is a cutting-edge device used to precisely assess the thermal diffusivity of diverse materials. With its sophisticated calculation models, it is at the forefront of scientific innovation, assuring the accuracy required for materials analysis.

- Measurements up to 1250 °C: The LFA 717 HyperFlash® HT is an innovative thermal analysis equipment that can detect temperatures up to 1250 °C using advanced xenon flash lamp technology. This unique solution removes the need for laser categorization, making it simple to use and in accordance with safety rules.

- Broad sample range: The LFA 717 HyperFlash® can accept various sample materials, including round and square forms.

- Vacuum-tight furnace for controlled atmosphere: The vacuum-tight furnace contains an internal pump that automatically evacuates the chamber before each measurement, maintaining a defined atmosphere for precise results. It also has extra ports for external pumping equipment, increasing operational flexibility. The furnace is meant to create controlled atmospheres that successfully stop oxidation during heating processes.

- Time-saving mini-tube furnaces: The four alumina mini-tube furnaces offer unparalleled test speed and outstanding sample throughput over the temperature range, supporting high heating rates of up to 50 K/min. Since each of the four sample positions has its own thermocouple, stabilization times are quick. These efficient and precise furnaces are perfect for demanding applications in labs and research centers since they can monitor 10 temperature steps from room temperature to 1250 °C in just one hour.

- Advanced corrections specifically for thin and highly conductive samples: The most recent version of the analysis program has an improved analysis pulse correction capability intended for high-precision applications requiring extraordinary time resolution. This amplification is especially useful when studying thin and highly conductive materials, as well as when the light pulse corresponds to the sample's temperature reaction.

The LFA 717 HyperFlash® HT is an indispensable instrument for researchers and companies that require accurate thermal property measurements, making it a valued asset in materials science.

Image Credit: NETZSCH-Gerätebau GmbH

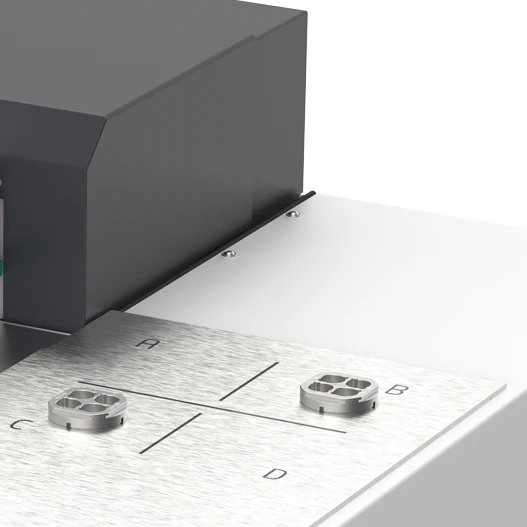

The instrument's top cover provides a convenient place for sample preparation and storage. It has been meticulously constructed with four visually different portions, each representing a separate sample position within the furnace. This novel design facilitates sample identification and pre-assembly, reduces instrument downtime, and is especially useful in multi-user scenarios.

Method

Efficient Determination of Thermophysical Properties with the Light Flash Method

Image Credit: NETZSCH-Gerätebau GmbH

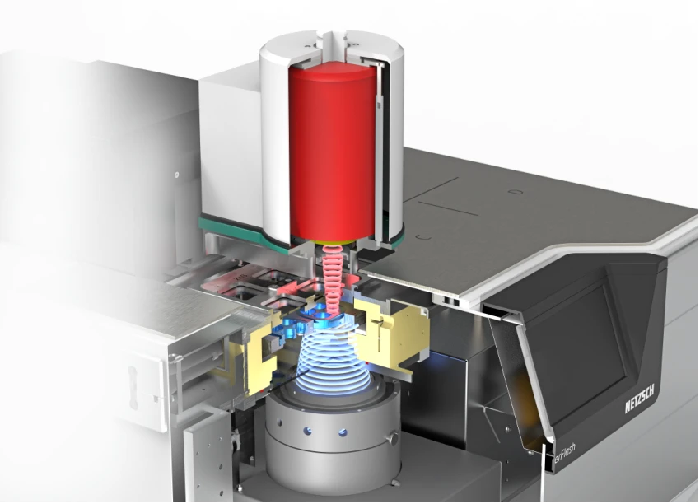

The Light Flash (LFA) technique is a quick, absolute, non-destructive, and non-contact way to accurately measure thermal diffusivity. This novel method assesses thermal diffusivity and describes the specific heat of materials when a reference sample is employed.

In the LFA method, a brief energy pulse heats the front surface of a plane-parallel sample. The ensuing temperature change on the back of the sample is measured using an infrared (IR) detector. This data can be used to characterize thermal diffusivity and specific heat.

To compute thermal conductivity, these thermophysical characteristics are coupled with density using the following formula:

λ(T)=a(T)⋅cp⋅ρ(T)

Where:

- λ = thermal conductivity [W/(m·K)]

- a = thermal diffusivity [mm2/s]

- cp = specific heat [J/(g·K)]

- ρ = density [g/cm³]

With its capacity to study a wide range of materials at different temperatures, the LFA approach is critical for researchers and industries interested in understanding thermal characteristics in depth.

Specifications

Source: NETZSCH-Gerätebau GmbH

| |

LFA 717 HyperFlash® HT |

| Temperature Range |

RT to 1250 °C |

| Heating rate (max.) |

50 K/min |

| Measured thermal properties |

Thermal diffusivity and specific heat capacity (and calculation of thermal conductivity) |

| Furnace cooling device |

External chiller |

| Thermal diffusivity |

0.01 mm2/s to 2000 mm2/s |

| Thermal conductivity |

0.1 W/(m·K) to 3000 W/(m·K) |

| Xenon flash lamp |

- Pulse energy: up to 10 Joules/pulse (variable), software-controlled

- Pulse width: 10 to 1500 μs

|

| ZoomOptics |

Patented; optimized field of view (optional, requires no mask) |

| Pulse mapping |

For finite pulse correction and improved cp determination |

| IR detectors |

- InSb: RT to 1250 °C

- Detector refill device (option)

|

| Vacuum |

10-4 mbar (with turbo pump) |

| Sample holders |

- Round and square specimen

- Liquids, pastes, resins, powders, lamellar specimen

- Tests under mechanical pressure

|

Proven Excellence in Service

Image Credit: NETZSCH-Gerätebau GmbH

NETZSCH Analyzing & Testing provides a complete variety of services worldwide to ensure your thermoanalytical equipment's best performance and lifespan. With a track record of proven quality, our services are designed to improve device efficacy, extend lifespan, and reduce downtime.

Software

Proteus® Software for LFA - Fast, Efficient, and Seamlessly Integrated!

Image Credit: NETZSCH-Gerätebau GmbH

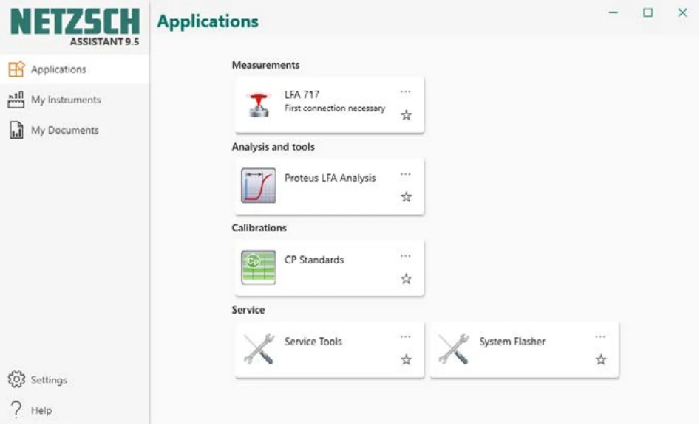

The Proteus® 64-bit software is licensed with each instrument, allowing users to connect numerous instruments via USB simultaneously or run the software on separate computer systems.

This software package, included in the NETZSCH Assistant beginning with version 9.5, connects a diverse set of NETZSCH instruments and third-party apps into a unified administration platform.

The switch from the previous database format to a new, quicker SQL database format is a significant improvement unique to Laser Flash Analysis (LFA). This improvement in data architecture improves modeling speeds and can provide results up to 2.5 times faster while utilizing less memory.

As a result, users can now store practically any amount of metrics in a single database. All common management features remain fully supported, including import/export and data merging.

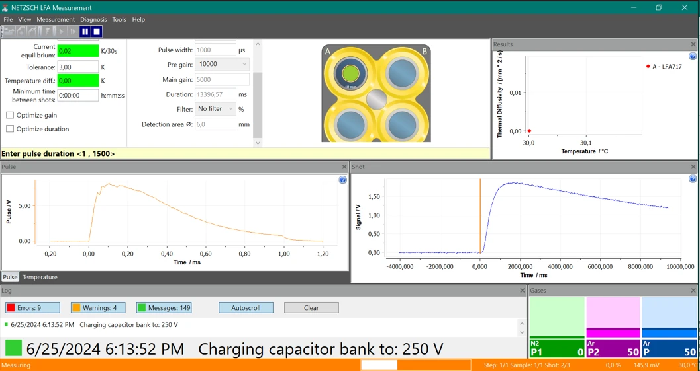

Proteus LFA Measurement Software

The LFA 717 HyperFlash® HT measurement software is a critical tool for connecting and managing instrument and hardware accessories, enabling users to successfully establish, monitor, and optimize measurements. The software is designed to improve automation and provides a high level of flexibility, making it suitable for a variety of sectors.

Image Credit: NETZSCH-Gerätebau GmbH

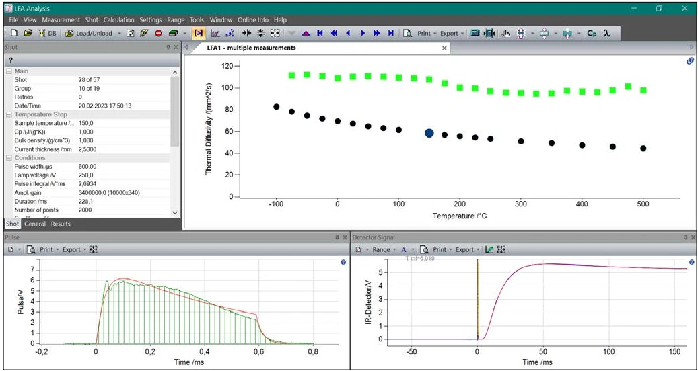

Proteus LFA Analysis Software

In addition to measuring capabilities, the specialized, stand-alone Proteus® LFA analysis software performs comprehensive data analysis using analytical models. The key features include:

Comprehensive Data Analysis

Users can simultaneously analyze multiple measurements within a single plot, eliminating the need for post-processing. This streamlining saves time and improves accuracy.

Export Detailed Documentation

Proteus® LFA offers a wide range of export options for creating complete results documentation, which is essential for quality assurance and reporting purposes.

Save Analysis States

Preserving analysis states enables convenient sequential analysis, making it easier to execute follow-up analyses without starting again.

Image Credit: NETZSCH-Gerätebau GmbH

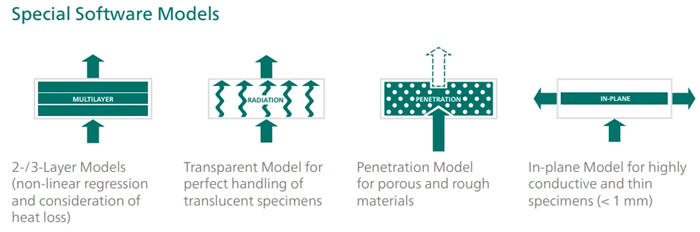

Models and Corrections

Unmatched mathematical models that are incorporated for accurate and transparent evaluation. Apart from the so-called modified Cape-Lehman model, which is the standard model for opaque, homogeneous, and isotropic samples, there exist models for specific application needs and adjustments.

Image Credit: NETZSCH-Gerätebau GmbH

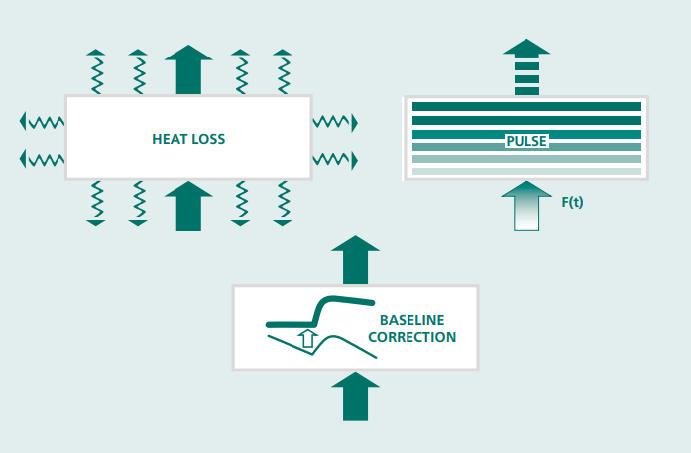

Light pulse and baseline correction are standard on all models for optimal fit and performance. The user can disable these adjustments. Heat loss is considered by all of the models stated above, and the adiabatic (Parker) Model is also accessible.

Image Credit: NETZSCH-Gerätebau GmbH

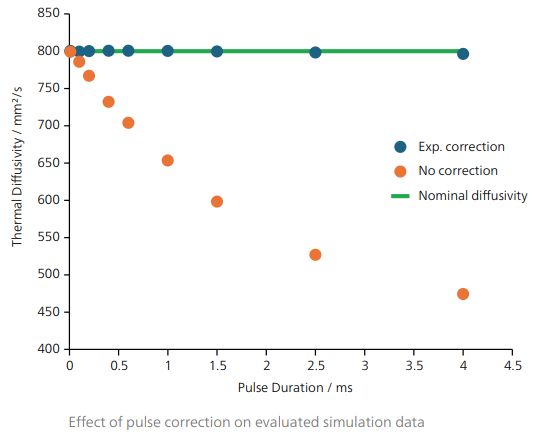

Enhanced Pulse Correction

NETZSCH-Gerätebau is proud to provide a sophisticated and precise pulse correction tool in the most recent edition of our analysis software. This improvement is especially helpful for thin or highly conductive materials because it enables users to access samples that need extraordinary time resolution. It is especially helpful when the light pulse and the sample's thermal reaction overlap.

Users can choose from a range of correction procedures inside the calculation dialog:

- Equivalent Square

- Center of Gravity

- Double Exponential Pulse Correction

Impact on Model Function and Fit Quality

Implementing pulse correction has a major impact on the look of the model function and its goodness of fit. Below is an example of a high-diffusivity material with a thermal diffusivity (α) of 800 mm2/s, with a 1 ms pulse signal added to the detector signal.

Whether or not the exponential pulse correction is implemented, the variation in calculated thermal diffusivity can be greater than 20%. This emphasizes the vital need for applying pulse correction procedures to obtain accurate analytical findings.

Image Credit: NETZSCH-Gerätebau GmbH

This Instrument is LabV®-Primed

Image Credit: NETZSCH-Gerätebau GmbH

LabV® collects data from the analytical instrument. The LabV® software securely stores all measurement data. This feature enables users to see and search data in LabV®. The data can be accessed now from anywhere. Furthermore, users can produce reports.