The line of Asphalt Bitumen Testing Equipment from Applied Test Systems (ATS) has been an essential part of the SHRP asphalt research program and its Superpave system. Every new system has been fitted with state-of-the-art, exclusive ATS software. It offers a sleek, digital touch screen, which enables users to test and record data easily.

For users searching for a highly simplistic and affordable testing solution, the BBR2S model is available without a touchscreen and has also been updated with the latest BBR2S software. Users can guarantee that they stay ahead of the curve with the company that has a notion towards the future.

Pyro-Clean® Series

Developed to burn off test residue from laboratory equipment, it enhances earlier versions and integrates automatic operation, cutting-edge touchscreen technology, and a clean, matte-black design.

Image Credit: Applied Test Systems

Lab technicians do not need to depend on wire brushing, scraping, or hand heating to clean equipment. Operators can place everything in their Pyro-Clean®, click start, and enable the machine to operate. This decreases mess, saves time, and creates a safer and highly efficient laboratory environment. With the availability of CE certification, European customers can experience all that the Pyro-Clean® has to provide as well!

Features

- CE certified

- Low operating costs enable users to save both money and time

- Industrial strength touchscreen display and improved ATS software

- Ideal for use in injection molding, asphalt, and organic chemistry applications

- Durable black powder-coated exterior, whereas all metal components exposed to the process are stainless steel

- Completely automatic: saves valuable lab time by eliminating the need to hand-clean equipment or monitor cleaning

- Consists of two adjustable, catalyst-filled shelves to house a range of equipment and sample holder sizes

- Removes even trace residues of organic contaminants, leaving lab equipment ultra-clean for crucial testing

- Decreases or removes dangerous waste material disposal, the dangers of glass breakage, and the entire mess linked to manual equipment cleaning

- Developed using over five decades of process heating and materials testing industry experience

Product Specifications

Table 1. Source: Applied Test Systems

| . |

. |

| Cleaning Temperature |

User adjustable, factory set at 900 °F |

| Safety Features |

Built in over pressure protection and shut off, automatic door lock, auto safety shutdown upon over temp, loss of draft, and numerous other conditions |

Oven Capacity

(Size Options) |

2.5 cubic feet

5.2 cubic feet |

| Interior Dimensions |

(2.5 cu ft) 14.9 in W x 18.5 in D x 16 in H

(5.2 cu ft) 23 in W x 19.5 in D x 20 in H |

| Power Requirements |

240 VAC, 1 ph, 50/60 Hz, 30 A |

| Exterior Dimensions |

(2.5 cu ft) 38 in W x 33 in D x 60 in H

(5.2 cu ft) 46 in W x 33 in D x 63 in H |

| Approx. Weight |

(2.5 cu ft) 380 lb

(5.2 cu ft) 450 lb |

| RTFO Bottle Capacity |

(2.5 cu ft) 64 bottles

(5.2 cu ft) 112 bottles |

Pressure Aging Vessel (PAV4)

The PAV4 has been designed to simulate the in-service oxidative aging of asphalt binder by exposure to high temperatures in a pressurized environment.

In-service oxidative aging of asphalt binder has been simulated by the ATS Pressure Aging Vessel (PAV4) via exposure to high temperatures in a pressurized environment. The PAV4 consists of an easy-to-use touchscreen, and new and improved software, offering the greatest level of reliability and efficiency during testing. Every PAV4 complies with ASTM D6521, AASHTO R28, and EN 14769 test standards.

Image Credit: Applied Test Systems

Features

- CE certified

- Enhanced recovery time of 30 minutes or less

- Black powder-coated exterior is durable

- Platinum RTD temperature measurement

- Comes with an industrial-strength touchscreen display and enhanced software

- USB port on the front of the unit is responsible for making data downloads and software upgrades simple

- Consists of 10 AASHTO T 179 specimen pans and also a solid, secure precision anodized aluminum specimen holder

- Optional battery backup system avoids test interruption or data loss as a result of line voltage fluctuations or power failure

- Data acquisition parameters include temperature, time, and pressure

Product Specifications

Table 2. Source: Applied Test Systems

| . |

. |

| Unit Design |

Benchtop unit with integral vessel/oven design |

| Specimen Capacity |

10 TFOT sample trays |

| Operating Pressure |

2.10 ± 0.05 MPa (304 psi) |

| Temperature Range |

90 °C to 115 °C ± 0.1 °C. Programmable from 50 °C to 150 °C |

| Power Requirements |

208-240 VAC, 1 ph, 50/60 Hz, 10 A |

| Dimensions |

27.5 in W x 18 in D x 30 in H |

| Weight |

290 lb |

Vacuum Degassing Oven (VDO Touch)

The ATS Vacuum Degassing Oven (VDO Touch) has been engineered to eliminate air bubbles produced.

Image Credit: Applied Test Systems

This was done while integrating updated software and touchscreen abilities to improve the testing experience of the users. The ATS VDO Touch complies with AASHTO R28, ASTM D6521, and EN 14769 test standards.

Features

- Industrial strength touchscreen display and improved software offered

- Comes with programmable vacuum time, temperature, and soak times

- Platinum RTD temperature measurement is given

- Remote connection enables users to track and regulate their VDO Touch offsite

- Comes with optional ATS system verification kit

- Consists of 4 eight-ounce containers and a specimen removal tool

Product Specifications

Table 3. Source: Applied Test Systems

| . |

. |

| Unit Design |

Bench Top Unit |

| Specimen Capacity |

4 eight-ounce or 8 four-ounce specimen containers |

| Product Dimensions |

24 inches wide x 16 inches deep x 12 inches high |

| Weight |

78 lbs. |

| Temperature Range |

Ambient to 392 °F (200 °C) |

| Temperature Accuracy |

0.2 °F (±0.1 °C) |

| RTD Temperature Measurement Accuracy |

Class A RTD at max. temperature ±1 °F (±0.55 °C) |

| Over-Temperature Protection |

Disc Thermostat open on rise Auto reset, Open 425 °F ± 15 °F (218 °C ± 8 °C), Close 375 °F ± 20 °F (191 °C ± 12 °C) |

| Vacuum Range |

6.6 KPA |

| Power Requirements |

115 V / 60 Hz or 230 V / 50 Hz |

Rolling Thin Film Oven (RTFO)

Applied Test Systems (ATS) introduces the new RTFO. This upgraded, less costly version comes with a powder-coated exterior, tough, sealed high temp bearing, and an accessible bottom tray for simple cleaning.

Image Credit: Applied Test Systems

Rolling Thin Film Oven (RTFO Touch)

Developed to simulate short-term asphalt binder aging according to ASTM D2872, AASHTO T240, Superpave, EN 12607, and California Test Method 346 test standards.

Image Credit: Applied Test Systems

Since 1965, Applied Test Systems (ATS) has been manufacturing custom furnaces and ovens and further entered into the asphalt binder testing market in the early 1990s.

The ATS RTFO Touch integrates years of experience in process heating and asphalt binder testing, making it highly easy-to-use and efficient testing equipment.

Having developed to simulate brief aging of asphalt binder as per the ASTM D2872, EN 12607, AASHTO T240, Superpave, and California Test Method 346 test standards, the RTFO Touch provides tailorable options and intuitive software to house an extensive spectrum of users.

Features

- CE certified

- Double walled stainless steel interior has the potential to retain a temperature of up to 205 °C (401 °F)

- Durable black powder-coated exterior available

- Easy-to-use touchscreen display

- Comes with NIST traceable platinum RTD

- NIST traceable digital flow meter is available

- USB Port on the front available for data downloads and software updates

- Remote monitoring communication can be performed

- Data acquisition included

- Heat-recovery time around 5 minutes

- Programmable airflow, temperature, and duration of the aging process available

- End-of-process alarm (both audible and visual)

Product Specifications

Table 4. Source: Applied Test Systems

| . |

. |

| Specimen Capacity |

8 high-temperature glass bottles |

| Temperature Range |

0 °C to 205 °C ± 0.5 °C |

| Air Requirements |

A source of clean, dry air with 60-150 psi |

| Speed Control |

Within 15 ± 0.05 RPM |

| Power Requirements |

208-240 VAC, 1 ph, 50/60 Hz, 10 A |

| Dimensions |

34 in W x 28.25 in D x 32 in H |

| Weight |

270 lb |

Exclusive Features

Sealed high temp bearings located outside of the heat zone for zero maintenance and durability. Image Credit: Applied Test Systems

Silicone rings allow for easy installation and prevent damage to bottles. Image Credit: Applied Test Systems

The bottom tray and elements are easily accessible for cleaning and upkeep. Image Credit: Applied Test Systems

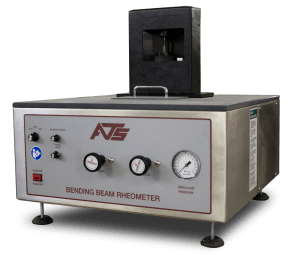

Bending Beam Rheometer 2S (BBR2S)

Designed to execute flexural tests on asphalt binder or bitumen and identical specimens per BS EN 14771, ASTM D6648, and AASHTO T313.

Image Credit: Applied Test Systems

Bending Beam Rheometer 3S (BBR3S)

BBR3S has been designed to execute flexural tests on asphalt binder and similar specimens per AASHTO TP 87, AASHTO T 313, ASTM D6648, and BS EN 14771 specifications as part of the PG grading system as per Superpave.

Image Credit: Applied Test Systems

The ATS Bending Beam Rheometer 3S (BBR3S) executes flexural tests on asphalt or bitumen binder and similar specimens per AASHTO T 313, ASTM D6648, AASHTO TP 87, GOST 58400.8-2019, and BS EN 14771 specifications as part of the PG grading system as per Superpave.

An ATS original, the BBR3S is the first of its kind to provide a cutting-edge internal computer system, integrating intuitive new software and touchscreen technology.

Features

- Enhanced temperature control algorithms stability integrating a next-generation controller.

- Redesigning the calibration disk and weight pan standardizes the LVDT sensor with a decreased chance for possible error by reducing changes in positioning the weight pan at the time of standardization.

- Test data comes in HTML and CSV

- Comes with 12″, industrial strength touchscreen display

- New stirrer motor guarantees exceptionally long motor life due to no moving parts. It has a particularly quiet operation and is unaffected by moisture

- Remote monitoring capabilities provided

- Programmable test parameters include load plot, deflection plot, bath temperature, testing times, load, specimen size, and testing company

- Optional changeable specimen assists simple transition for crack sealant testing

- Small external chiller with decreased noise during operation

- Customizable report settings—add company notes, logo, and accreditations

Product Specifications

Table 5. Source: Applied Test Systems

| . |

. |

| Load Frame Construction |

Integral stainless steel, frictionless construction |

| Loading Shaft Point |

In-line stainless steel with blunt point |

| Test Load |

Variable test range from 0 to 4,500 mN (459 g) standard. System maintains required test load within +/- 5 mN (0.5 g) throughout test cycle. |

| Test Cycle Times |

Cycle times for pre-load, recovery, and test load are completely operator-adjustable. |

| Load Cell |

500 g (temperature-compensated) |

| Mechanical Overload Protection |

Standard |

| Testing Temperature Range |

0 to -40 °C (32 to -40 °F) |

| Temperature Measurement |

Platinum RTD |

| Power Requirements |

115 VAC, 1 ph, 50/60 Hz, 2 A or 230 VAC, 1 ph, 50/60 Hz, 2 A |

| Air Pressure |

60 psi inlet pressure (414 kPa) @ Class 3 Quality max particle of 5 μm |

| Test Weights |

Calibrated and traceable to NIST |

| Rating |

IP20 Enclosure rating |

| Sample Supports |

3 mm (0.118 in) radius stainless steel spaced 101.6 mm (4.00 in) apart |

| LVDT Displacement Transducer |

0.25 in (6.35 mm) calibrated range to provide 2 μm resolution throughout testing and verification range. |

| Data Display |

Large on-screen display of load, displacement, and bath temperature provides ease of setup and operation. Real-time displacement, loading, and temperature graphs are displayed during the test cycle and can be re-plotted and re-scaled as needed for easy viewing. |

| Tank Liquid Volume |

1.5 gallons (5.5 liters) |

| Weight |

150 lb |

| Dimensions |

BBR: 24 in W x 26.5 in D x 23.5 in H (with load frame)

Chiller: 10.5 in W x 20 in D x 9.25 in H |

SHEAR1

SHEAR1 is a smooth tool for testing hot mix asphalt (HMA) to identify the shear parameters in association with the permanent deformations of asphalt mixtures in a uniaxial repeated shear test along with horizontal deformation limitation.

Image Credit: Applied Test Systems

Series 510 Sealant Tester

The Series 510 Sealant Tester has been utilized for testing sealing compounds, coatings, construction adhesives, and other building test materials. It fulfills ASTM D 5329 and ASTM D 6690 test specifications.

Image Credit: Applied Test Systems

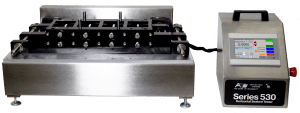

Series 530 Sealant Tester

Developed to execute Aymar Type Tests at 1/8″ per hour at variable speeds of 1/8–2 1/2″per minute as per ASTM C 910, ASTM C 736, ASTM C 719, ASTM C 1305, ASTM D 6690, FEDERAL SS-S200, ASTM D 5329, and FEDERAL TT-S230.

Image Credit: Applied Test Systems

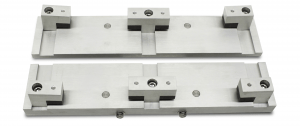

Series 530 Sealant Tester Roofing Fixture

Extra fixtures for the Series 530, enabling the operator to test polymer-modified bituminous membrane specimens to ASTM D 5329, ASTM D 5849, and ASTM D 6690 test specifications.

Image Credit: Applied Test Systems

Series 540

Adaptable and computer-controlled touch screen system developed for load capacities of up to 4,000 lbf (17.7kN). This fixture provides dual load rods for even load distribution. The Series 540 meets ASTM C719, C910, C920, C736 abd ASTM D 5329 testing specifications.

Image Credit: Applied Test Systems