ATS provides a comprehensive line of lab furnaces and high-temperature accessories that are world-renowned for their quality and dependability, with basic lab furnace designs and styles. Mounting brackets and accessory items are available to make installation and startup as simple as possible.

Applied Test Systems (ATS) has developed an unrivaled line of accurate and affordable materials testing equipment since 1965. A significant portion of this effort has gone toward high-temperature testing and production.

ATS has compiled an extensive line of furnaces and high-temperature accessory items unrivaled in quality, versatility, and reliability due to over 50 years of research, development, design, testing, and re-testing.

The standard ATS furnace line is intended for general laboratory use as well as testing to ASTM standards and other specifications. All ATS furnaces are built to order in a wide range of diameters, lengths, sizes, and configurations and come complete with mounting brackets and accessory equipment.

Depending on the temperature requirements and the specific application, heating elements are available in various materials and configurations.

Furnaces have been designed to easily replace failed elements in the laboratory, saving time and money.

Exceptional design features such as low K-factor vacuum-cast ceramic fiber insulation and low-watt-density heating elements provide substantial advantages and benefits to the user, such as lower power consumption, faster heat up, longer element life, and lower shell temperatures.

Various furnace designs are available, including tube, split tube, box, split box, high temperature, low-profile, silicon carbide, molybdenum, and controlled atmosphere.

With over 50 years of custom testing equipment design experience, ATS offers an optimal solution for all high-temperature testing and manufacturing needs.

ATS manufactures a full range of laboratory testing machines and accessories, including universal testing machines, creep/stress-rupture test frames, convection ovens/cryogenic cooling chambers, pressure testing systems, asphalt testing equipment, and sealant testers, in addition to furnaces.

It also offers grips, fixtures, load train components, extensometers, ultrasonic reference standards, and other components.

Series 3110/3210 Tube and Split Tube Furnace

The most popular line is the ATS Series 3110/3210 Tube and Split Tube Furnaces.

This series has been meticulously designed and refined, resulting in one of the most dependable and effective laboratory furnaces today. These furnaces can be used in connection with different materials testing machines, in gas processing systems, on their own, and in various other applications.

Features

- Low K-factor vacuum-cast ceramic fiber insulation

- Tailored for specific requirements

- Stainless steel shell and end flanges

- A wide range of diameters, lengths, mounting arrangements, and accessory equipment are available.

- Replaceable heating elements

- There are numerous configurations available, including isothermal, gradient, adiabatic, and others

- Heat-equalizing liners, thermocouples, extensometer slots and mounting flats, viewports, end caps, cast bronze, gas ports, or ceramic fiber heating elements, retorts, and other accessories are available

Image Credit: Applied Test Systems

Series 3110/3210

- Length and zone construction made to order

- Other sizes provided on request

- Heating elements and temperature range: Nichrome: 1850 °F (1000 °C) Kanthal A1: 2200 °F (1200 °C)

- NRTL and CE Listed (in standard configurations, selected sizes only, with approved control system)

Series 3150/3160 Box and Split Box Furnace

The ATS Series 3150/3160 Box and Split Box furnaces are the box-style counterparts to the Series 3110/3210 tube and split tube series, and they share many of the same advanced design and construction features.

Features

- Stainless steel shell

- Tailored for specific requirements

- Low K-factor vacuum-cast ceramic fiber insulation

- Replacement elements are available

- All Series 3150/3160 Furnaces have a maximum temperature rating of 1200 °C (2192 °F)

- Wide range of available widths, heights, and depths, mounting configurations, and accessory equipment

- Standard replaceable ceramic hearth plate

- Heat equalizing liners, extensometer slots and mounting flats, thermocouples, end caps, viewports, gas ports, cast bronze or ceramic fiber heating elements, retorts, and other accessories are available.

Image Credit: Applied Test Systems

Series 3150 Front Load Box Furnace for AMS 2750 Testing

The ATS Series 3150 for AMS 2750 Box Furnace is a particularly augmented furnace based on the time-tested 3150 box furnace design with enhanced heating uniformity features. This furnace has a supplied port for the customer’s thermocouples during the TUS, making it ideal for those working with the AMS 2750 requirements.

The port reduces insulation damage, which is essential to maintaining furnace performance. During uniformity testing, three areas cause failures: burned-out elements, wear to the door and wear to the front face of the furnace.

These concerns were addressed by providing long-lasting hardboard insulation on the front and a blanket fiber-lined door that is easily replaceable. If the elements ever need to be replaced, it is as simple as unplugging the terminals and pulling them out.

Features

- Standard construction features include a durable stainless-steel shell and ceramic fiber insulation

- Replacement elements are available

- All Series 3150 Box Furnaces have a maximum temperature rating of 1200 °C (2192 °F)

- Standard replaceable ceramic hearth plate

Image Credit: Applied Test Systems

Exclusive Features

Blanket-filled door for a positive seal that allows for easy customer replacement. Image Credit: Applied Test Systems

Ceramic tube port for thermocouples during temperature survey. When not in use, an insulating plug is supplied. Image Credit: Applied Test Systems

Wall-mounted elements for easy access with no insulation removal required for replacement. Image Credit: Applied Test Systems

Series 3410/3420 Silicon Carbide Tube and Split Tube Furnace

The ATS Series 3410 and 3420 Silicon Carbide Tube and Split Tube Furnaces are a line of high-efficiency, steady-heat furnaces with operating temperatures up to 2800 °F (1540 °C). Unlike the ATS Series 3300 high-temperature models, this series has been developed for a slower and steadier heat-up, which is useful for operations involving various materials.

Features

- Tailored specific requirements

- Stainless steel shell and end flanges

- Low K-factor vacuum-cast ceramic fiber insulation

- Wide selection of available diameters, lengths, mounting arrangements, and accessory equipment

- Replaceable, long-lasting Silicon carbide (SiC) “rammed rod” type heating elements

- Available options and accessories include thermocouples, end caps, viewports, and retorts

Image Credit: Applied Test Systems

Series 3450 Silicon Carbide Box Furnace

The ATS Series 3450 Slicon Carbide Box Furnaces are the box-style counterpart to the ATS Series 3410/3420 Furnaces. This Series, capable of operating temperatures up to 2800 °F (1540 °C), has been crafted for slow and steady heat-up rates with minimal temperature losses.

Features

- Custom built-to-order to suit specific requirements

- Low K-factor vacuum-cast ceramic fiber insulation

- Stainless steel shell

- Wide selection of available widths, heights, and depths, mounting arrangements, and accessory equipment

- Double-pivot door hinge

- Replaceable, long-lasting Silicon carbide (SiC) “rammed rod” type heating elements

- Available options and accessories include thermocouples, viewports, gas ports, and more.

Image Credit: Applied Test Systems

Series 3310/3320 High-Temperature Tube and Split Tube Furnace

ATS Series 3310/3320 Tube and Split Tube Furnaces up to 3272 °F (1800 °C) are also available for higher temperature testing. The heating elements in series 3310 and 3320 are Molybdenum Disilicide (MoSi2), which provide fast heat-up rates and easy replacement.

Features

- Low K-factor vacuum-cast ceramic fiber insulation

- Tailored to meet specific requirements

- Replaceable Molybdenum Disilicide (MoSi2) heating elements

- Wide selection of available diameters, lengths, mounting arrangements, and accessory equipment

- Stainless steel shell and end flanges

- Available options and accessories include extensometer slots and mounting flats, thermocouples, end caps and port plugs, viewports, and more

Image Credit: Applied Test Systems

Image Credit: Applied Test Systems

Series 3330 High-Temperature Furnace

ATS Series 3330 High-Temperature Furnaces offer an ideal low-profile solution to restricted testing space due to specimen size or other factors. These furnaces feature highly compact construction while maintaining efficient temperature capabilities up to 3000 °F (1650 °C). Due to a small internal working volume, rapid heat-up and cool-down rates are attainable for testing ceramics, metal alloys, composites, and other materials using flat or round specimens.

Features

- Replaceable Molybdenum Disilicide (MoSi2) heating elements

- Low K-factor vacuum-cast ceramic fiber insulation

- Stainless steel shell and element covers

- Standard: One or Two Heating Zones

- Custom Zone arrangements available

- Available options and accessories include high-temperature extensometers, extensometer slots, thermocouples, viewports, water cooled specimen grips, and testing fixtures.

Image Credit: Applied Test Systems

Series 3350 High-Temperature Box Furnace

The ATS Series 3350 High-Temperature Box Furnaces are high-efficiency, rapid heat-up/cool-down laboratory chambers operating at temperatures up to 3272 °F (1800 °C). These furnaces have an excellent design and construction, as well as multiple layers and grades of insulation materials, sustaining uniform temperatures with minimal heat losses.

Features

- Custom built-to-order to suit specific requirements

- Stainless steel shell and durable interior

- Low K-factor vacuum-cast ceramic fiber insulation

- Wide selection of available widths, heights, and depths, mounting arrangements, and accessory equipment

- Full opening front door/Double-pivot door hinge

- Replaceable Molybdenum Disilicide (MoSi2) heating elements

- Available options and accessories include thermocouples, viewports, gas ports, and more.

Image Credit: Applied Test Systems

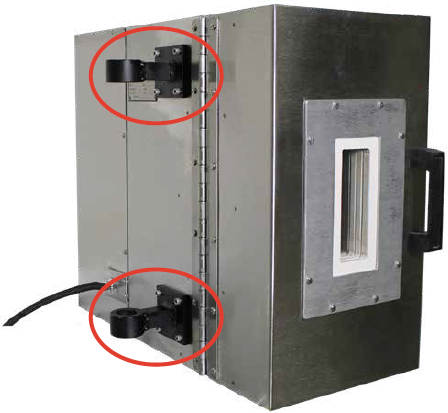

Series 3350 High-Temperature Controlled Atmosphere Box Furnace

ATS developed a customized version of the standard Series 3350 High Temperature Box Furnace. This unit is one of a kind because it can hold an atmosphere—either argon or nitrogen. The system is intended to purge the furnace of air and backfill it with argon from a tank provided by the user.

This design provides the customer with a low-cost way to run the furnace without oxygen, enabling them to avoid purchasing a separate vacuum furnace. The leveler mounts on this custom Series 3350 High Temperature Box Furnace are made of heavy gauge stainless steel. It can reach temperatures of up to 1700 °C. An altered shell with water-cooled seals and a water manifold with valves keeps the inert atmosphere at bay.

Features

- Single end door with hardened vacuum cast insulation

- Molybdenum Disilicide elements

- Flow switch provides automatic power down due to flow loss

- 2-Type B thermocouple with insulator, connector, and 2-Sealing gland for power connections

- Low range relief valve, 2 psi

- 2-Gas Ports: 1/4 in. dia., inlet and outlet

- Roughing Pump: 3.2 dfm with mist eliminator, valve, and gauge

- Optional load train ports for use on tensile testing machines

Image Credit: Applied Test Systems

Image Credit: Applied Test Systems

Image Credit: Applied Test Systems

Furnace Accessories

Thermocouple Assemblies

- Single Bracket

- Duplex Bracket

- Spring-Loaded

- Sealed

Removable End Caps

Ports

- Viewports

- Gas Inlet and Outlet ports

- Explosion ports

- Purging ports

- Cooling and Vent ports

- Load Train ports

Extensometer Ports and Slots

Zone Dividers

Element Protection Shields

Perforated Heat Shields

Sealed Terminal Covers

Heat Equalizing Blocks

Sealed Retort Assemblies

Special Door Hinges

Various Mounting Arrangements

- Removable

- Offset

- Double-pivot

Temperature Control Systems

A furnace’s precision is limited by its control system. ATS places a premium on providing complete, precise temperature control systems that use only high-quality components. ATS control systems were chosen for their accuracy, versatility, and dependability. On request, custom control systems using any major-brand temperature controller, including Watlow, Eurotherm, and others, are also available.

Ovens

ATS offers a comprehensive line of world-renowned ovens and accessories for their quality and dependability. The outstanding features, combined with the expertise of design engineers, place the ovens among the most durable and efficient on the market today. ATS ovens are available in a variety of standard sizes and can be easily customized to meet user-specific requirements. The cutting-edge equipment can be delivered to the user with any accessories and mounting that they require.

Applied Test Systems (ATS) has been manufacturing standard and custom ovens for a variety of testing, laboratory, and industrial processes since 1965. Materials testing ovens are designed to be mounted on testing frames produced by ATS and other companies. Ovens could be used during any of the following tests: compression, tension, creep/stress rupture, sheer, flexure, constant stress, stress relaxation, and adhesive/sealant testing.

Manufacturing and laboratory process ovens can be used for annealing, bonding, baking, curing, pre-heating, drying, heat treating, stress relieving, and a variety of other processes. ATS offers two standard series of ovens in box and split box configurations. All ovens have a stainless steel external shell and are available in standard and custom sizes to meet the needs of individual customers.

Custom mounting configurations can also be created to meet the testing requirements. Quality insulation, a recirculating air and plenum system, a continuous door hinge, a resilient seal, a quick acting latch closure, and a stainless steel shell are all outstanding design features.

Oven accessories can be purchased separately or in conjunction with an oven. Mounting brackets, cooling apparatus, temperature controllers, retorts, view ports, and portable dollies are among the accessories available.

Series 3700 Standard Ovens

The stainless steel internal liner and stainless steel external shell of the Series 3710 Box and Series 3720 Split Box Ovens make the ovens both durable and easy to clean. This series' temperature range is -155 ºC to 425 ºC (-250 ºF to 800 ºF).

Features

- Tailored for specific requirements

- Replaceable heating elements

- Stainless steel shell and liner

- “CE” marked units available

- A double plenum feature is added for superior temperature uniformity

- Available options and accessories include viewports, thermocouples, gas ports, internal light, hand ports, explosion port, mounting, cooling, and more

Image Credit: Applied Test Systems

Series 3700HT High-Temperature Ovens

The Series 3710 High-Temperature (HT) Box and 3720 High Temperature Split Box Ovens have a stainless steel internal liner and external shell. They also feature twice the insulation for the higher temperature range of -185 ºC to 620 ºC (-300 ºF to 1150 ºF).

Features

- Built-to-order to meet specific requirements

- Twice the insulation as the Standard 3700 Ovens

- Stainless steel shell and liner

- Higher power requirements than the Standard 3700 Series

- A double plenum feature is added for superior temperature uniformity

- “CE” marked units available

- Replaceable heating elements

- Available options and accessories include thermocouples, viewports, gas ports, internal light, hand ports, explosion port, mounting, cooling, and more

Image Credit: Applied Test Systems

Series 3700 Oven Accessories

Thermocouple Assemblies

Ports

- View ports

- Gas ports

- Load train ports

- Hand access ports

- Explosion ports

Inserts

- Load train port inserts

- Removable plugs

Rear Protection Cover

- Comes standard with all ovens

Special Door Hinges

Door Switch

Cuts off power to the elements, solenoid, and blower motor when door is opened.

Cooling Accessories

- Liquid Nitrogen (N2) assembly with service to -155 °C (-250 °F)

- Liquid Carbon Dioxide (CO2) assembly with service to -57 °C (-70 °F)

- Solenoid valve, Cryogenic service

- Explosion Proof Motor

Internal Light Assembly

Various Mounting Arrangements

Temperature Controllers

Oven Mounting

ATS ovens can be used in a laboratory or mounted on a material testing machine for various testing applications. ATS provides a diverse range of mounting options to meet laboratory requirements.

Stationary Column Mount. Mounting brackets attach the oven to the columns of a test machine. Image Credit: Applied Test Systems

Stationary Base Mount This arrangement uses mounting brackets to attach the oven to the base of a test machine. Image Credit: Applied Test Systems

Column or Base Mount Slide Assembly. Mounting brackets attach the oven to the columns or base of a test machine. The slide assembly allows the oven to slide out of position when necessary. Image Credit: Applied Test Systems

Portable Dolly. Ovens can be mounted to the lift of an ATS portable dolly. Manual and hydraulic lifts are available for vertical adjustment. Image Credit: Applied Test Systems

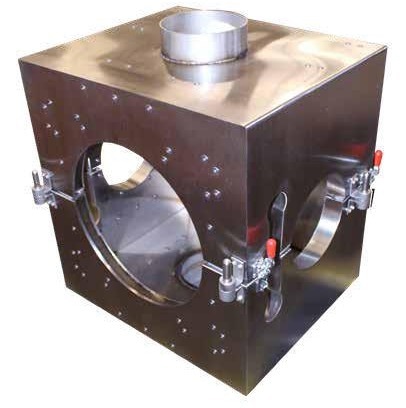

Custom Oven Examples

Image Credit: Applied Test Systems

Image Credit: Applied Test Systems

Image Credit: Applied Test Systems