The latest SIGMA Testing System represents a significant advancement in Creep and Stress Rupture testing by Applied Test Systems. This cutting-edge system incorporates state-of-the-art machinery, control hardware, and WinCCS software.

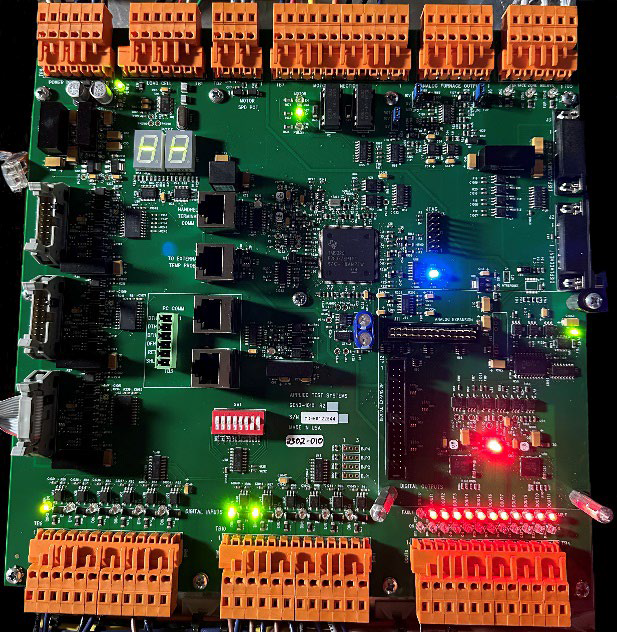

Gen 3 Hardware

Faster Microcomputer

The system has a swifter single-chip microcomputer featuring integrated memory and program storage in flash memory. The new processor boasts a performance increase of over 100 times compared to the GEN1/GEN2 processors, resulting in enhancements across all facets of the controller’s operation.

Advanced Speed Controls

In earlier systems, the manual load speed potentiometer was linked to an external motor controller, causing numerous testing problems when customers failed to reset the manual potentiometer to its standard operating position at the test's start.

The new system features a direct input for the manual load speed potentiometer, ensuring that the software determines when to utilize this input, effectively eliminating any issues arising from operator errors.

Temperature and Humidity Sensor

The system has been incorporated with a NIST-traceable temperature and humidity monitor that is safely mounted to the tester’s laboratory setup.

It makes sure users have a constant record of the environmental conditions in the laboratory integrated within their test data by automatically recording data, such as temperature and humidity embedded in the test data. Additionally, during calibration and verification processes, the sensor captures ambient conditions.

Improved Thermocouple Measurement

The new units offer a notable enhancement in thermocouple reading speed, achieving 30 readings per minute compared to the GEN1/GEN2 units, which provided only one reading per minute. This substantial improvement contributes to a much more rapid furnace response following transient events, like brief power outages.

Cold Stepped Loading

The introduction of Cold Stepped Creep loading enables operators to load the specimen at lower temperatures before initiating a test and generating a report.

This functionality allows operators to assess the extensometry setup’s performance prior to commencing the actual test. Furthermore, this cold loading procedure can be specified as an integral part of the test, serving as an additional validation of the extensometer setup.

Image Credit: Applied Testing Systems

Stepper Motor Drive

The incorporation of an advanced Stepper Motor control system enhances load control precision and facilitates hot and cold stepped loading. This is a significant advancement in stepper motor control capabilities and allows precise load management, enabling stress relaxation tests to be seamlessly conducted on the same machine.

Improved Load Measurement

Enhanced load cell measurement technology enables quicker adjustments in load control.

Sampling Rate

The system has an enhanced data sampling rate of 60 samples per minute or one sample per second.

Super Capacitor

The updated hardware employs a supercapacitor as a calendar clock backup instead of a lithium battery. This eliminates the need for battery replacements and avoids shipping restrictions on the hardware.

With the removal of lithium batteries, the control boards can now be shipped by air without any limitations, and spare boards are not subject to battery shelf-life constraints.

Solid State Memory

Solid-state ferromagnetic FRAM is used to store reading and test settings, negating the requirement for backup RAM powered by lithium batteries. This results in a significantly more reliable storage method for readings in case of a PC failure. It is important to note that this memory is utilized for storing readings when the host computer is not online.

Fault Display

The onboard digital fault display offers advanced diagnostics, facilitating quicker troubleshooting.

32-bit Encoder I/F

Introducing a 32-bit optical digital encoder measurement interface ensures the hardware’s readiness for longer-term use and the potential incorporation of higher-resolution optical digital encoders.

Analog Outputs

Analog outputs are employed for furnace control, particularly for high-temperature furnaces with analog power controls.

Light Bar

A manufacturing-style light bar is implemented to provide a clear visual indication of the machine and test status, visible from various locations throughout the laboratory.

Cyclic Stress Testing Option

Enables users to designate cyclic unloading of the specimen throughout the test, with the option to specify this operation for the entire test or a predetermined number of cycles.

When combined with the SIGMA controller, this feature enables faster data acquisition during the specimen's actual loading and unloading phases, ensuring the generation of an accurate load profile graph.

Stress Relaxation Option

It conducts tests in either Constant Stress, Constant Strain, or Constant Strain as per ASTM E328. The new SIGMA Controller, with its enhanced computing speed, data acquisition capabilities, and stepper load train control, provides precise control in stress and strain modes that were previously unachievable.

Gen 3 Portable Display

Image Credit: Applied Testing Systems

OLED Display

The high-resolution OLED display enhances visibility in various lighting conditions.

Jog Controls

Jog controls for the machine are equipped with indicator LEDs.

Faster Microcomputer

A swifter processor for more seamless display performance.

Backwards Compatible

Compatible with both GEN2 and GEN3 controllers.

Languages

Provides direct support for a wide range of language fonts.

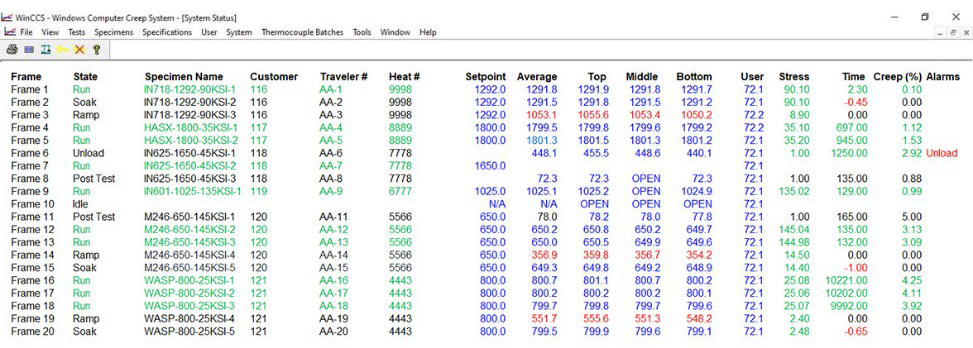

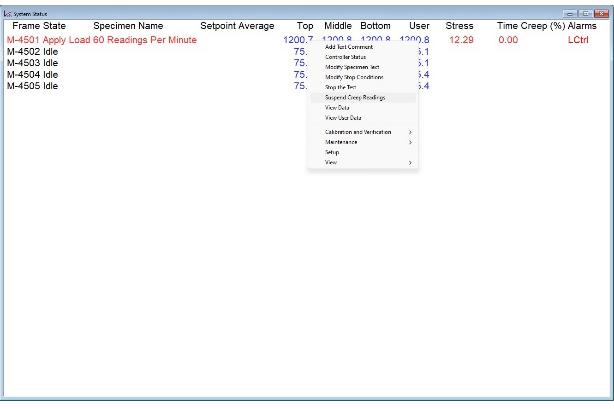

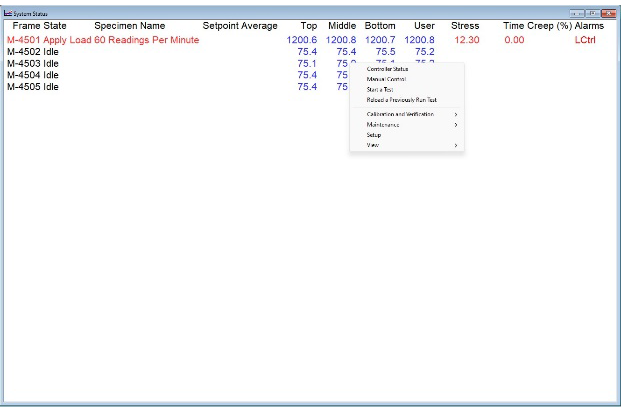

Version 8 WinCCS

Optional LIMS Integration

A new feature has been introduced in the WinCCS system, offering optional integration with Laboratory Information Management Systems (LIMS).

With this integration, users can seamlessly import various data, including specimen details, test specifications, specimen measurements, thermocouple batch information, and more, from their LIMS system into the WinCCS system.

Additionally, complete test records can be exported from WinCCS to the LIMS. The data exchange process is streamlined through the use of XML data files, making implementation straightforward. The LIMS integration includes support for reducing errors by enabling barcode scanning of specimen bags.

Image Credit: Applied Testing Systems

Image Credit: Applied Testing Systems

HTML Reports

HTML Reports simplify the process of exporting reports to clients. HTML formatting is a widely accepted standard for documents, making it effortless to email and view reports in a web browser.

Status Display

The updated system status display, featuring context-sensitive menus, enables quicker navigation to control functions tailored to each testing machine.

Image Credit: Applied Testing Systems

Image Credit: Applied Testing Systems

Furnace Logging

Enhanced furnace logging routines now capture additional parameters in the logs.

“Date”,” Avg Tmp”,”Ctrl T/C”,”S.P.”,”Rate”,”Err”,”Pwr,”P Term”,”I Term”,”D Term”,”% Stop”,”% Smid”,”% SBot”,”% Top”,”% Mid”,”% Bot”,”Top T/C”,”Mid T/C”,”Bot T/C”,”Wall T/C”,”ACV”,”Iso Tmp.”

Running Test Modifications

Adjust test termination parameters during an ongoing test.

Creep Loading Validation

The company has implemented additional checks in the Hot and Cold Loading reports to automatically assess if a test might be experiencing extensometer setup or binding issues.

Once the test is hot stepped loaded the system will evaluate the loading data and if any issues are detected it will show the test frames data in red, indicating an issue and display a “Hid” in the Alarms column. The test will continue normally, but this alerts the operator that this test should be examined to determine if it should be continued.

Elongation Methods

Incorporated the 4D, 4W, 5D, 5W, and two customized elongation methods.

Time Resolution

Elevated the time resolution from seconds to milliseconds (ms) to accommodate the higher data acquisition rates of the SIGMA Hardware.

Compatibility

Provides comprehensive support for all WinCCS hardware, both past and present.

Languages

The latest language support features seamlessly integrate language prompts into the code base, effectively resolving the issue of version mismatches in prompt files. Additionally, this enhanced language capability facilitates the use of multiple languages.

The same approach has been integrated into the GEN3 hardware firmware, eliminating the necessity for lengthy prompt file downloads.

Setup

Enhancements in system setup now enable the effortless duplication of frame setups, streamlining the deployment of large-scale systems.

Load Calibration and Verifications

Load calibration is enhanced, as well as verification routines, to ensure that more than one run can be carried out in ASTM E4.

Test Specifications

Imrpove the test specification editor to provide clearer instructions regarding shutdown procedures and pass-fail criteria for discontinuing tests.

System Status

Introducing a new system status file. In previous versions, a system status file in CSV format was generated every minute for external systems to utilize in reporting test statuses. With Version 8, three distinct types of system status files have been incorporated, as outlined below.

Pre Version 8 CSV Format

Lab Number, State, Average Temperature, Time in Hours, Percentage Creep.

New CSV Format

Frame, Lab Number, State, Average Temperature, Time in Hours, % Creep, Load, Top, Middle, Bottom and User.

Version 8 XML Format

System Status

The system status file grants user systems access to the system’s status. In earlier versions, it featured a basic CSV format with restricted parameters.

In Version 8, users can opt for the original CSV format, an enhanced CSV format, or an XML file. The XML file contains the most extensive information and is recommended for new implementations.