Aerospace standards are met by the CMOS X-Ray detector, DR 7 NDT, which is used for ultra-high resolution X-Ray inspection and testing.

Image Credit: DÜRR NDT GmbH & Co. KG

Ultra High Resolution

The 19 μm pixel pitch generates excellent data.

Time to Image

Enhanced efficiency via rapid processing.

Compact Design

Adaptable positioning choices that are widely applicable.

Most Important Features

Image Credit: DÜRR NDT GmbH & Co. KG

The DR 7 NDT is perfect for small tubes because of its compact shape, which also allows it to be placed within objects or in difficult-to-reach areas.

The CMOS X-Ray detector has a robust aluminum outer layer and a strong carbon layer covering its 36×26 mm active surface to ensure optimal performance in a demanding test environment.

The PC USB port is used to immediately connect to and power the X-Ray detector. Included is a 4.5-meter cable that can be extended to a 9 m length if needed.

Technical Data

Source: DÜRR NDT GmbH & Co. KG

| |

DR 7 NDT |

| Active area |

26 x 36 mm (1.0 x 1.4") |

| Dimensions (H x W x D) |

31.5 x 50 x 8.3 mm (1.24 x 1.97 x 0.33") |

| Number of pixels |

1,368 x 1,896 = 2,593,728 |

| Pixel pitch |

19 μm |

| SRb (Basic Spatial Resolution) |

25 µm |

| Grayscale resolution |

16-bit |

| Interface |

USB 2.0, USB 3.0 compatible |

| Cable length |

4.5 m (active extension possible) |

| Software |

DÜRR NDT D-Tect 9.5 or higher |

Sample Images

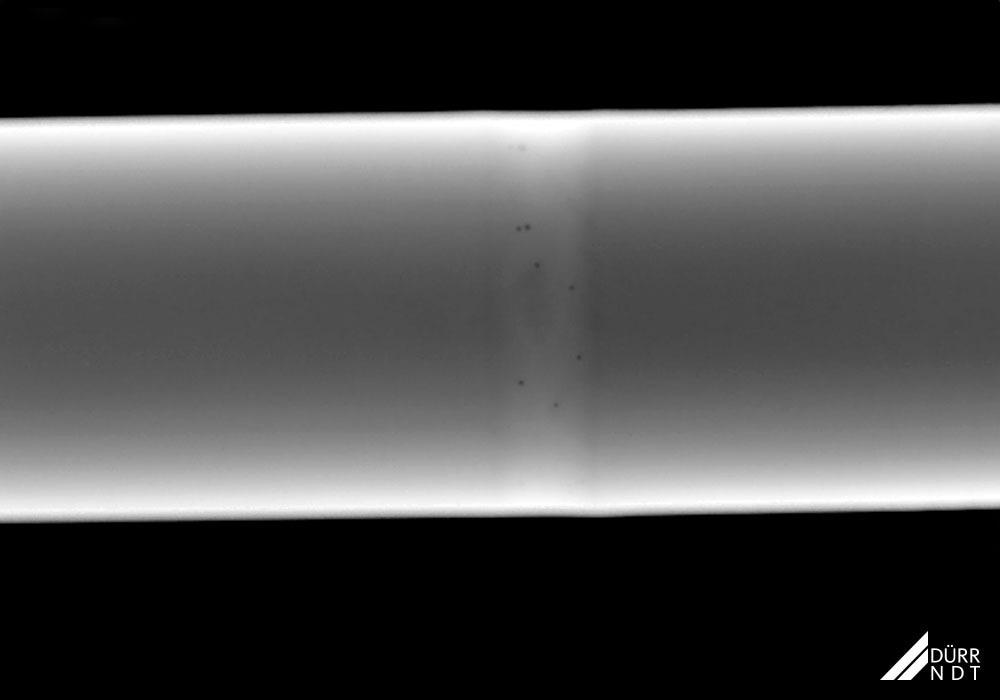

Weld seam with multiple pores, Ø 13 mm titanium pipe, X-ray, perpendicular technique. Image Credit: DÜRR NDT GmbH & Co. KG

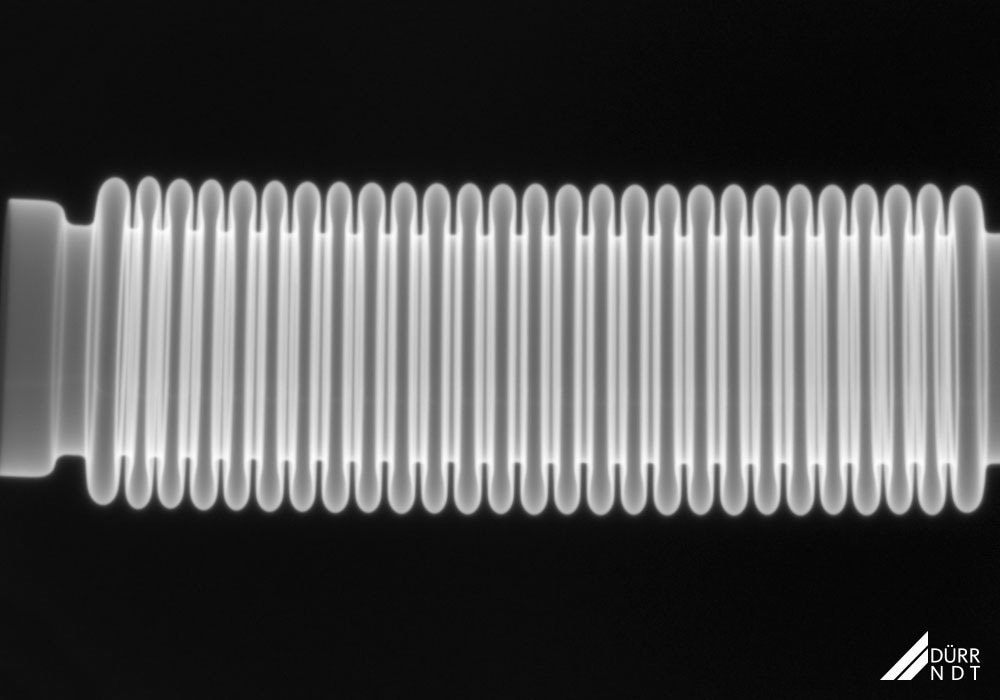

Stainless steel bellows, aerospace, X-ray, profile exposure to evaluate the bending geometry. Image Credit: DÜRR NDT GmbH & Co. KG

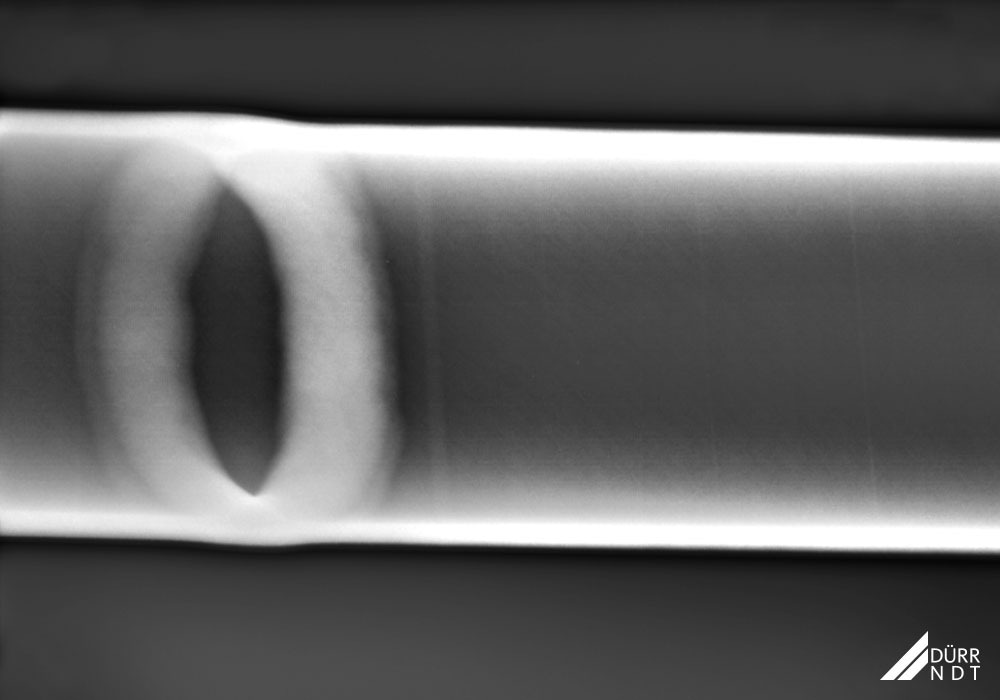

Weld seam, Ø 14 mm stainless steel pipe, X-ray, elliptic technique. Image Credit: DÜRR NDT GmbH & Co. KG

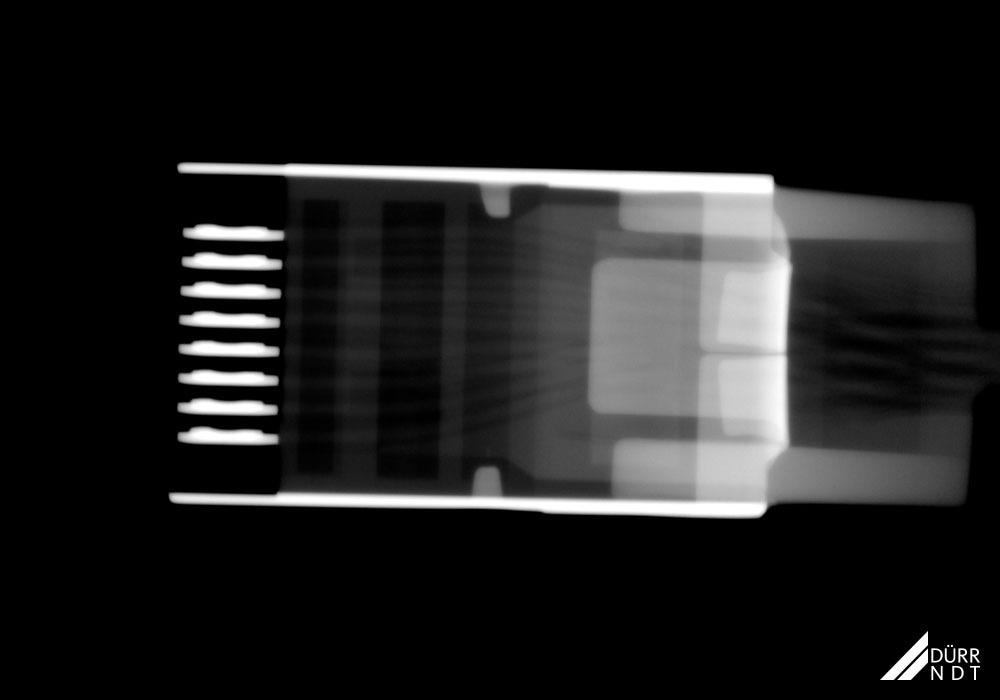

Connector plug, X-ray, evaluation of electrical connections. Image Credit: DÜRR NDT GmbH & Co. KG