GE Global Research has reported the latest research results of its nano-textured anti-icing surfaces at the 2012 March Meeting of the American Physical Society.

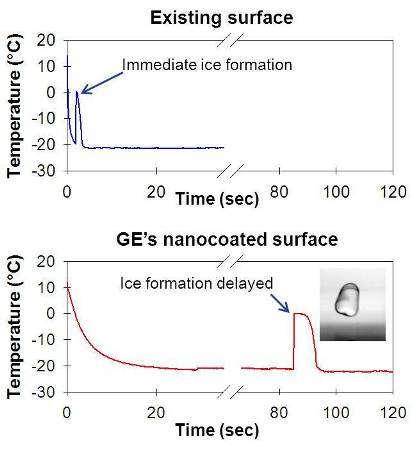

The above figures show the benefits of GE's nanocoatings in delaying ice formation when compared with existing surfaces. Scientists at GE Global Research measured the onset of icing by monitoring the temperature of a supercooled drop of water on the surface, using an infrared camera. The spike in the drop temperature indicates the start of icing.

The above figures show the benefits of GE's nanocoatings in delaying ice formation when compared with existing surfaces. Scientists at GE Global Research measured the onset of icing by monitoring the temperature of a supercooled drop of water on the surface, using an infrared camera. The spike in the drop temperature indicates the start of icing.

Besides drastically decreasing ice adhesion, GE’s nano-enabled anti-icing surfaces have been demonstrated to considerably delay the formation of ice by over one minute on their own in simulated atmospheric icing environments.

GE Global Research’s Materials Scientist and Project Lead on the anti-icing surfaces program, Azar Alizadeh informed that the company has successfully designed novel nano surfaces and coatings that substantially delay ice formation and readily shed ice under extreme conditions. These technologies have the potential to decrease or even eliminate the necessity for current de-icing and anti-icing measures taken by airlines and other industries, thus ensuring safety and saving time and money of consumers and businesses.

Alizadeh further said that GE is investigating promising applications of anti-icing and low ice adhesion coatings and surfaces across its business portfolio. Although the company has achieved positive results in the lab and in other tests, more research is needed to develop further its nano-enabled anti-icing surfaces and coatings to make it suitable for commercial applications.

The research on nanotextured anti-icing coatings and surfaces comes under GE’s research program on advanced nanotechnology at GE Global Research. GE researchers have designed the novel nanotextured coatings and surfaces based on a nanotextured wax found on the surface of leaves of lotus plants that make them repel water. In addition to the anti-icing surfaces, GE scientists are designing super water-repellent coatings to enhance efficiency of steam turbines by improving moisture control. They are also working on employing these coatings for some components of a gas turbine to decrease fouling, thus decreasing maintenance time and improving efficiency.