J.G Finneran Associates has reported the release of the new 96-Well PTFE Sealing Film. The adhesive film has a patented design, which is used to seal samples present in microplates in high throughput bioanalytical studies. Samples are not exposed to the sealing adhesive of the film. They are sheltered from evaporation and cross contamination.

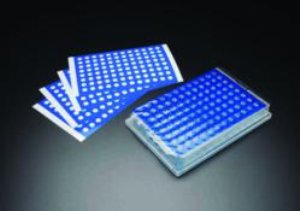

96-Well PTFE Sealing Film

96-Well PTFE Sealing Film

Solvent-free adhesive lined on the new 96-Well PTFE sealing film has been applied in such a way as to form a seal surrounding all 96 wells, ensuring that the region above the sample is void of adhesive. Contamination of the sampling probe or pipette tip is prevented because of the design of the adhesive sealing, which reduces the amount of adhesive in line with the sample. The formulation of adhesive is designed in such a way that it can adhere to polycarbonate, polypropylene and polystyrene microplates. The inert PTFE sealing film suits well with organic solvents and aqueous solutions, and it is resistant to majority of the laboratory chemicals. The range of functional temperature of this sealing film is -80ºC to +120ºC. Robotic probes and single or multi-channel pipettors can easily pierce the adhesive film, which is available at a thickness of 2 and 5 mil.

The company specifically designs, develops and produces new plastics and glass products in ISO certified facilities. J.G Finneran jointly working with customers has expanded most of the containment systems and sample vials to discover the ways to increase the efficiency and productivity.