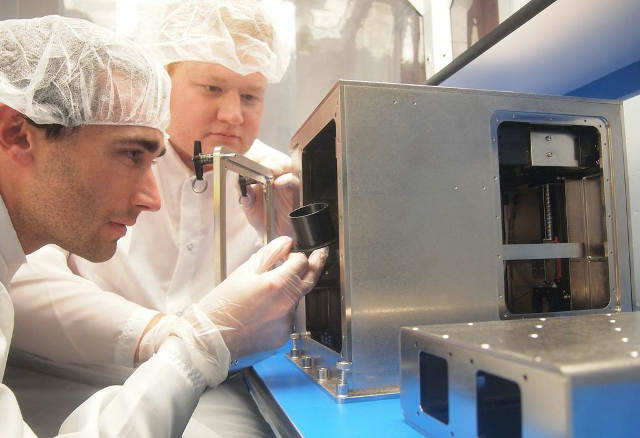

Mike Snyder and Jason Dunn, both from Made In Space, assemble the 3-D printer that will fly to the International Space Station in the company's cleanroom. Image credit: Made in Space

Mike Snyder and Jason Dunn, both from Made In Space, assemble the 3-D printer that will fly to the International Space Station in the company's cleanroom. Image credit: Made in Space

A customized 3D printer that allows fabrication of all necessary tools and components required for a space mission will be sent to the International Space Station aboard the SpaceX-4 resupply mission this month.

The 3D printer was developed by Made In Space, which received a Small Business Innovation Research (SBIR) award as part of the 3D Printing In Zero-G Technology Demonstration program at NASA's Marshall Space Flight Center to develop the first 3D printer capable of working in microgravity.

The 3D printer successfully completed all flight certification and acceptance testing in April 2014 at Marshall.

NASA's engineers are keen to demonstrate that a 3D printer can operate as normal in space, and print components with a similar quality to those fabricated on earth.

If the 3D printer successfully completes the tests lined up for it aboard the space station, it will become the first step toward the establishment of a working "machine shop" in space.

This will pave the way to lower cost, lower risk, and more efficient missions on the ISS, by supplying the necessary tools and replacement parts on demand.

Onboard manufacturing capabilities would be highly beneficial to long-term missions. The knowledge gained in this 3D printer demonstration will be helpful in optimizing future 3D manufacturing technology and devices for the space mission, such as the Additive Manufacturing Facility (AMF).

The program is supported by the International Space Station Technology Development Office in Houston, as well as the Game Changing Development Program and the Advanced Human Exploration and Operations Mission Directorate at NASA Headquarters located in Washington.