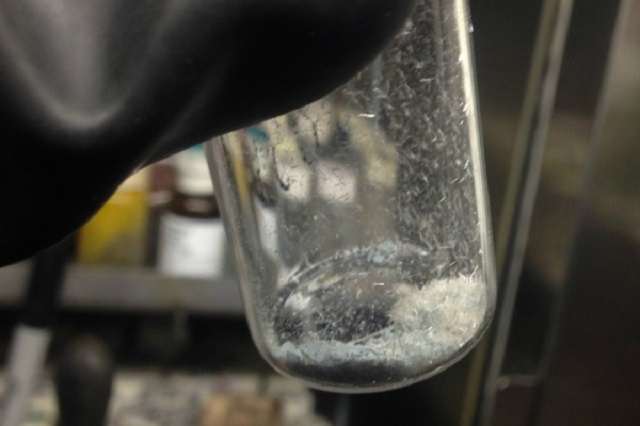

Starting with the two elements as a mixed powder, a metal-binding molecule known as a ligand is applied.

Starting with the two elements as a mixed powder, a metal-binding molecule known as a ligand is applied.

Researchers at the University of Pennsylvania have developed a simple, efficient method for recycling rare earth magnets. These materials are widely used in consumer electronics, however the process of mining and purifying rare earth metals damages the environment, and is very costly and labor-intensive.

The Penn process is designed for recycling neodymium and dysprosium, which are two rare metals. Many high-tech devices contain magnets made from these two metals. The innovative Penn process requires only standard laboratory equipment and room temperature conditions, and works almost instantaneously. Other conventional industrial processes are massive and require huge amount of energy.

Recycling of electronics to obtain neodymium and dysprosium would be an eco-friendly, less-expensive method, when compared to mining these metals from the ground.

Size differences mean that ligand-neodymium complexes bind with one another, while their dysprosium counterparts do not.

Eric J. Schelter, assistant professor in the Department of Chemistry in Penn’s School of Arts & Sciences, led the study along with Justin Bogart, a graduate student. Patrick J. Carroll, director of the University of Pennsylvania X-Ray Crystallography Facility, and Connor A. Lippincott, an undergraduate student in the Vagelos Integrated Program in Energy Research, were other contributors to this study.

Neodymium magnets can’t be beat in terms of their properties. They give you the strongest amount of magnetism for the smallest amount of stuff and can perform at a range of temperatures.

Schelter

Neodymium is mixed in specific ratios with other elements to obtain the desired thermal qualities. Dysprosium is also used as an element for mixing. Different ratios are required for different applications. Hence the rare metals have to be separated and then mixed in the specific ratios for the desired application.

It’s, in principle, easier to get the neodymium and dysprosium out of technology than it is to go back and mine more of the minerals they are originally found in. Those minerals have five elements to separate, whereas the neodymium magnet in a wind turbine generator only has two.

Schelter

Currently, the liquid-liquid extraction method, which is an expensive, energy-intensive process, is used for purifying the neodymium and dysprosium in old power tool motors or in minerals. In this method, the composite material is dissolved and the elements are chemically filtered. This process has to done on an industrial scale due to the necessity to repeat the process thousands of times in order to obtain pure rare earth metals.

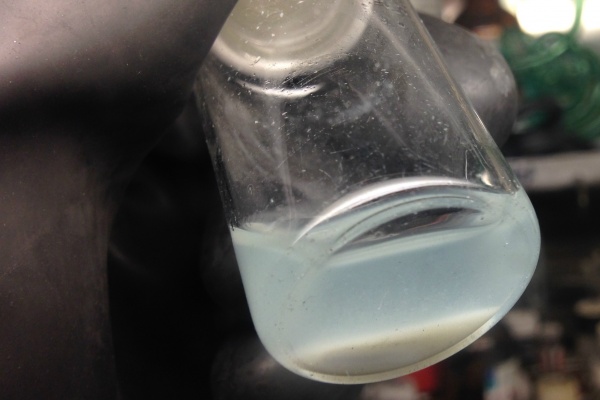

This binding increases the solubility of the neodymium over that of the dysprosium, allowing the former to be filtered off.

Schelter’s team has developed a novel method to separate the two metals.

When we started our goal was to make rare earth separations simpler and more efficient and we have made strides towards just that. We have designed a way to separate the two metals by selectively dissolving the neodymium in a solution and leaving behind the dysprosium as a solid. This quick and easy method has allowed us to separate equal mixtures of the metals into samples that are 95 percent pure.

Bogart

The two elements in powder form are mixed together and a ligand, which is a metal-binding molecule, is applied. The researchers designed a ligand having three branches that converge on the metal atoms and use the aperture between their tips to hold them. Neodymium is slightly larger in size; hence the tips do not get close together, in the same manner as around dysprosium atoms.

“The difference in size between the two ions is not that significant, which is why this separation problem is difficult,” Schelter said, “But it’s enough to cause that aperture to open up more for neodymium. And, because it is more open, one ligand-neodymium complex can combine with another, and that really changes its solubility."

When two neodymium complexes combine it is called as a dimer. This combination encapsulates the neodymium ions, which allows them to dissolve in benzene, toluene or other such solvents. However, in these solvents, dysprosium complexes do not dissolve, allowing separation of the two metals. After separation, the ligand can be removed from these metals using an acid bath. This ligand can also be recycled.

"If you have the right ligand, you can do this separation in five minutes, whereas the liquid-liquid extraction method takes weeks,” Schelter said. “A potential magnet recycler probably doesn’t have the capital to invest in an entire liquid-liquid separations plant, so having a chemical technology that can instantaneously separate these elements enables smaller scale recyclers to get value out of their materials."

Further research will endeavor to increase the ligand’s stability, so that it does not fall off easily before metal separation occurs.

"These results are encouraging," Bogart said. "We feel that through slight adjustments to the system, the purity level could be increased even further."

Modifying the ligand could facilitate recycling of rare metals in other technology products using this simple process.

The researchers have published this study in Angewandte Chemie, International Edition.

The Research Corporation for Science Advancement, and the U.S. Department of Energy’s Office of Science provided support for this study.

References