Jan 22 2016

A lithium-ion battery capable of self heating even if the temperature is less than 32°F can prove to be comforting as it could relieve winter "range anxiety" for owners of electric vehicles, according to a research team from Penn State and EC Power, State College. This self-heating battery also has a wide range of applications.

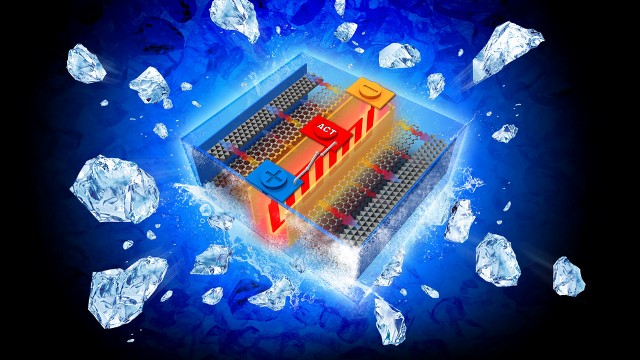

An all-climate battery that rapidly self-heats battery materials and electrochemical interfaces in cold environments. Image: Chao-Yang Wang / Penn State

An all-climate battery that rapidly self-heats battery materials and electrochemical interfaces in cold environments. Image: Chao-Yang Wang / Penn State

"It is a long standing problem that batteries do not perform well at subzero temperatures," said Chao-Yang Wang, William E. Diefenderfer Chair of mechanical engineering, professor of chemical engineering and professor of materials science and engineering and director, Electrochemical Engine Center. "This may not be an issue for phones and laptops, but is a huge barrier for electric vehicles, drones, outdoor robots and space applications."

Standard batteries at below freezing temperatures suffer severe power loss, leading to a slower charging rate in cold weather conditions, limited regenerative breaking, and a decline (as high as 40%) in vehicle cruise range. These problems require bigger and more expensive batteries to make up for the depletion of energy.

We don't want electric cars to lose 40 to 50 percent of their cruise range in frigid weather as reported by the American Automobile Association and we don't want the cold weather to exacerbate range anxiety. In cold winters, range anxiety is the last thing we need.

Chao-Yang Wang, Professor of Engineering

The researchers, aided by earlier patents of EC Power, developed the all-weather battery which weighs only 1.5% more, and costs only 0.04% of the existing battery. The battery is operational in 20 seconds at a temperature range of -4oF to 32°F, and in 30 seconds from -22oF to 32°. The battery only consumes 3.8% and 5.5% of its capacity, considerably less than the loss of 40% in traditional lithium-ion batteries.

The all-climate battery uses a thin nickel foil measuring 50 µm with one end connected to the battery’s negative terminal, the other end is extended outside the cell to create a third terminal. A temperature sensor is connected to a switch, and allows electrons to pass through the foil, completing the circuit. This arrangement rapidly heats the nickel foil via a resistance heating effect, and warms the interiors of the battery. Once the battery temperature reaches 32°F the switch is automatically turned off, so that electric current starts flowing in the usual manner.

Nickel, compared to other materials, is inexpensive and works well as a resistance-heating element.

Next we would like to broaden the work to a new paradigm called SmartBattery. We think we can use similar structures or principles to actively regulate the battery's safety, performance and life.

Chao-Yang Wang, Professor of Engineering

Others who worked in this project were; Guangsheng Zhang and Yongjun Leng, research associates in mechanical engineering; and Xiao-Guang Yang, postdoctoral Fellow, all at Penn State. Terrence Xu, Shanhai Ge and Yan Ji, innovation engineers, all at EC Power were also a part of this research. Wang is also the Chief Technology Officer and founder of the startup EC Power.

This project was supported by EC Power.