Jan 23 2017

The Italian hot runner specialist HRSflow will present in its Multitech line – in which HRSflow has expanded hot runner solutions for multi-cavity molds – new hot runner nozzles of the MTR range, designed for both thin-wall and thick-wall injection molding processes. Additionally, the company will inform about the advances of the partnership between HRSflow Multitech and Plastic Technologies, Inc. (PTI), a global leader in plastic packaging development for single-serve beverage and food capsules.

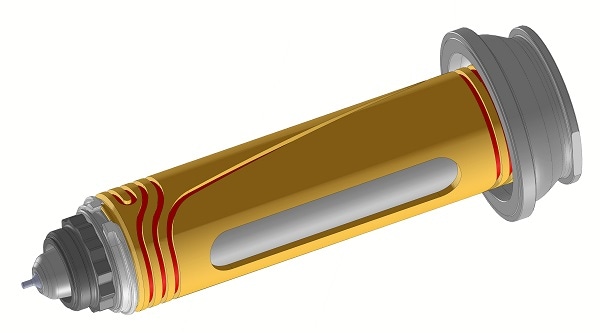

MTR hot runner nozzles for multicavity large scale production

In the multicavity sector, HRSflow Multitech offers hot runner solutions for injection molds designed for large-scale production of packaging, caps and closures, articles for medical technology, electrical and electronics, and the automotive industry. The focus here is on high cavity numbers, short cycle times, homogeneous balancing, and rapid color changes. The new MTR hot runner nozzle is available in three specifications: MTR-T, MTR-M and MTR-S. Their common distinguishing factor is the high resistance of the nozzle tip to wear and tear.

- MTR-T nozzle is specifically designed for the injection molding of large containers with wall thicknesses as from 0.45 mm and a flow length to wall thickness ratio up to 350. Injection pressures up to 2,200 bar and high melt throughputs up to 180 g/s can be attained. With its high process stability, this hot runner nozzle is also suitable for decorative injection molding using the IML process (In-mold Labeling).

- MTR-M nozzle offers advantages in the injection molding of polyesters to produce thick-walled parts with a high-gloss finish. When used for cosmetic packaging, household articles or in medical technology, wall thicknesses of 20 mm and more can be produced without problem.

- MTR-S type has also been developed for thick-walled parts with a wall thickness of up to 20 mm, but is geared specifically to the injection molding of Surlyn®, a crystal-clear ionomer from DuPont.

Reduced time-to-market for beverage and food capsules

Moreover with the explosive growth of single-serve beverage and food capsules, HRSflow Multitech and Plastic Technologies, Inc., a global leader in plastic package development, have partnered to provide brand owners with a turnkey commercialization pathway. The significant technical knowledge both companies have in this area will help improve speed-to-market and drive commercial success.