Apr 13 2017

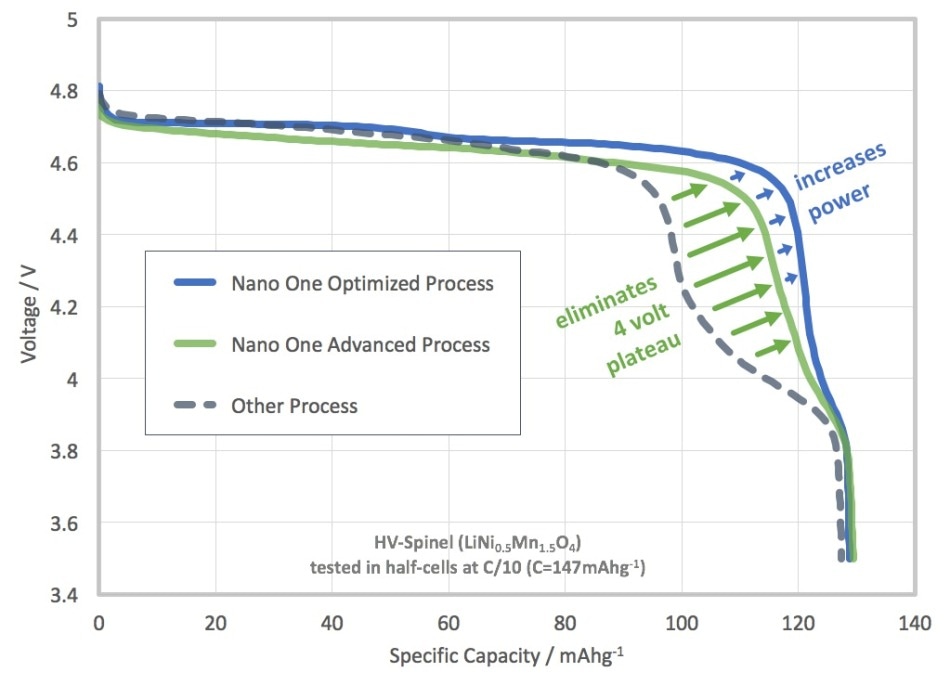

Initial discharge curves showing improved performance of High Voltage Spinel (LiNi0.5Mn1.5O4) using Nano One’s advanced and optimized process. Credit: Nano One

Initial discharge curves showing improved performance of High Voltage Spinel (LiNi0.5Mn1.5O4) using Nano One’s advanced and optimized process. Credit: Nano One

Dr. Stephen Campbell, Principal Scientist at Nano One Materials, announced process improvements that will help in boosting power and reducing the cost for lithium ion cathode materials.

I am pleased to report that recent optimization of Nano One’s proprietary process adds to the high voltage spinel improvements announced earlier this year. The Nano One process eliminates the 4-Volt plateau in the discharge curve allowing the delivery of constant power across the whole charge range. This is an important advantage for vehicle and stationary energy storage applications as the higher voltage reduces heating, aids durability and simplifies the power management systems. In addition, the absence of cobalt and the use of low cost lithium carbonate in our process directly address raw material constraints in the supply chain.

Dr. Campbell, Principal Scientist, Nano One Materials

These advances in technology were brought about by the constant support from the National Research Council of Canada Industrial Research Assistance Program (NRC-IRAP) under the Cobalt Free High Voltage Spinel project announced on June 30, 2016.

High-voltage spinel will be a vital component of next generation high power batteries and with the support of IRAP, Nano One is positioning its technology to play a key role in the commercialization effort.

Dr. Campbell, Principal Scientist, Nano One Materials