Jul 18 2017

An unusual interaction between metal and light can be harnessed to make chemical reactions more sustainable, but the physics underlying it has been extensively debated in the field.

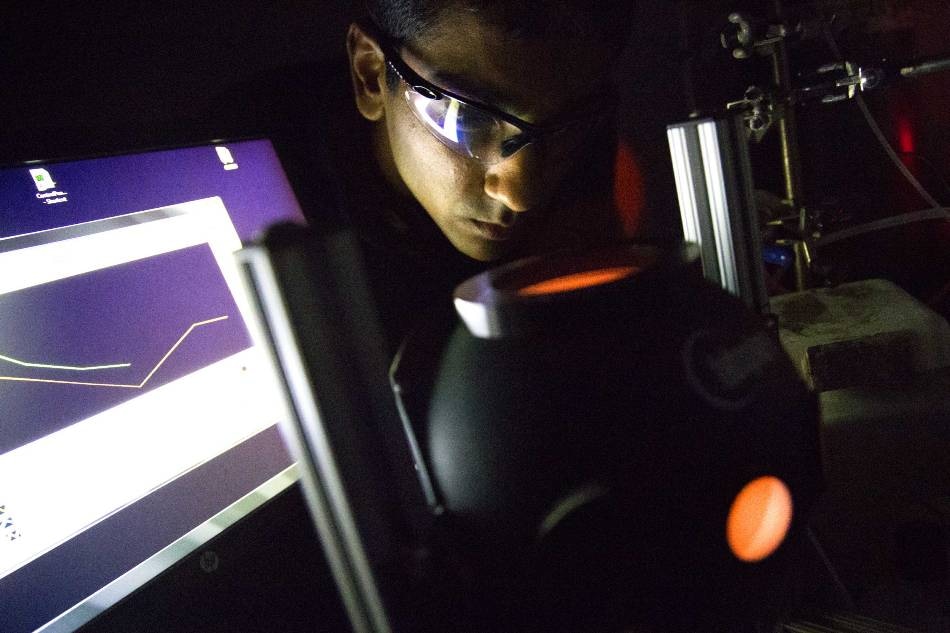

Umar Aslam peers into the light source used during the experiments that revealed how the silver nanocubes captured energy and delivered it to the platinum shells. (Image credit: Akhil Kantipuly, Michigan Engineering)

Umar Aslam peers into the light source used during the experiments that revealed how the silver nanocubes captured energy and delivered it to the platinum shells. (Image credit: Akhil Kantipuly, Michigan Engineering)

Recently, a research from the University of Michigan has revealed how a light-harvesting metal conveys energy to a catalytic metal, paving the way for improved catalyst designs.

Catalysts act as mediators of chemical reactions: they can make reactions take place at lower temperatures, decreasing the energy required, and they can also give an edge to a preferred reaction pathway, yielding more of the target chemical and reduced waste.

A new kind of catalyst can be created from plasmonic metals that are good at trapping the light, but they are not great at guiding reactions. To enhance their effectiveness, Researchers have been peppering them with materials that are superior catalysts, enhancing reactions related to fuel production and regular household products such as toothpaste, for instance.

The difficulty with earlier experiments was that there were many different exposed surfaces, so it gets very difficult to interpret your results because of the complexity of the nanoparticles.

Umar Aslam, U-M Doctoral Student in Chemical Engineering

Now, Aslam and his colleagues in the research group of Suljo Linic, a Professor of Chemical Engineering and a pioneer in plasmonic catalysis, have demonstrated how the energy travels. Instead of energetic electrons hopping from the light-capturer to the catalyst, the plasmonic metal is behaving more like a radio antenna, with the catalyst as the receiver, Aslam said.

Their experiment, published in the Nature Nanotechnology journal, was the first to persuasively demonstrate that this mechanism is at work.

We described how plasmonic nanostructures move the energy of light to the catalytically active sites. We then demonstrated how this mechanism can be exploited to design very efficient and selective catalysts.

Suljo Linic, a Professor of Chemical Engineering

Selectivity is prized because it decreases the undesirable "side" reactions that generate waste.

Copper, gold and silver are recognized for their plasmonic properties, or their ability to trap the energy of visible light in the form of waves in their surface electrons, known as surface plasmons.

In the experiment, Aslam and Steven Chavez, also a Doctoral Student in Chemical Engineering, created silver nanocubes, approximately 75 nm (millionths of a centimeter) to a side. They then coated these with platinum measuring just 1 nm in thickness.

Metal that thin is fundamentally transparent to light, so the coated silver continued to convert the light into surface plasmons. The silver then directed the energy to the platinum coating via the sea of electrons shared between them. The platinum created energetic electrons and positively charged holes—charge carriers that could then move forward to cause chemical reactions on its surface.

Platinum is widely thought to be "the emperor of all catalysts," which makes this material a clear choice for Researchers fascinated with plasmonic catalysis, Aslam said.

However, no one has been able to achieve it before because it is very challenging to coax a thin film of platinum onto silver. Under most circumstances, the silver tends to discolor, Aslam said. So he and Chavez modified the reaction conditions so that the platinum coating took place much faster than the tarnishing.

The team showed that the catalyst almost doubled the rate at which carbon monoxide contaminants in hydrogen converted into carbon dioxide when the light was on—compared to the reaction in the dark, which depends on the platinum alone. This conversion is crucial in the manufacture of hydrogen from methane, as waste carbon monoxide gunges up the catalysts in hydrogen fuel cells.

They exposed that neither the silver nanocubes alone—nor the cubic platinum shells remaining when the silver was removed by acid—could perform like the platinum-coated cubes. Still, Linic and Aslam state that these new catalysts are not yet forerunners of a revolution in industrial chemistry.

Right now, plasmonic catalysis is a nascent field. It costs more to prepare a catalyst like this compared to conventional catalysts.

Umar Aslam, U-M Doctoral Student in Chemical Engineering

But with continuing progresses in nanoparticle creation and ideas to additionally increase the efficiency gains offered by plasmonic catalysts, they may make the chemical sector greener in the days to come.

The research paper is titled, "Controlling energy flow in multimetallic nanostructures for plasmonic catalysis." The research was mainly supported by the National Science Foundation, with extra support from the U.S. Department of Energy and U-M College of Engineering.