Image Credits: Freeman Technology

Powder characterisation specialists, Freeman Technology, have expanded their global operations with the establishment of an office in Germany.

We have been working with businesses in Germany since the company was founded. It has long been a region with a significant number of powder processing companies across a range of industries. The region’s economic status is supported by competence in engineering and manufacturing. Following our recent expansions into other countries and the diversification of our product line, Germany was the obvious next step for Freeman Technology.

Tim Freeman, Managing Director, Freeman Technology

Headquartered in the UK, the company has specialised in the characterisation of powders since the late 1990s with the introduction of its flagship product, the FT4 Powder Rheometer®.

I am confident that the increased local support provided by our new operation, will further enable customers to benefit from the technologies and experience that Freeman Technology have developed over the last 17 years.

Tim Freeman, Managing Director, Freeman Technology

Daniel Weber joins the team as Product Manager and will be based in the region to provide sales and customer support.

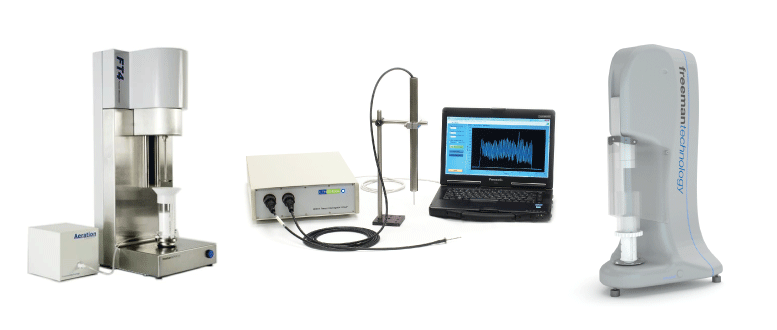

Freeman Technology’s solutions include the FT4 Powder Rheometer, a unique and comprehensive powder tester, which uses patented dynamic methodology, automated shear cells (in accordance with ASTM D7891) and a series of bulk property tests to quantify powder behaviour in terms of flow and processability. This is complemented by the Uniaxial Powder Tester, which provides an accurate and repeatable measure of the uniaxial unconfined yield strength (uUYS) of a powder to assess and rank flowability. The company also offers in-line, real-time flow measurement capabilities via an exclusive partnership with Lenterra Inc, manufacturers of optical flow sensor technology.

With nearly two decades of experience in powder flow and powder characterisation, expert teams assist users around the world to address their individual powder challenges, focusing on delivering the most relevant information for their processes. The result is world-leading solutions for understanding powder behaviour in development, formulation, scale-up, processing, quality control, or any area where powders are utilised.